HRCEA (hybrid of rules and compression-extensive algorithm)-based steel making-continuous casting production scheduling method for special steel mill

A production scheduling and continuous casting technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problem of not considering the key factors of the production mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

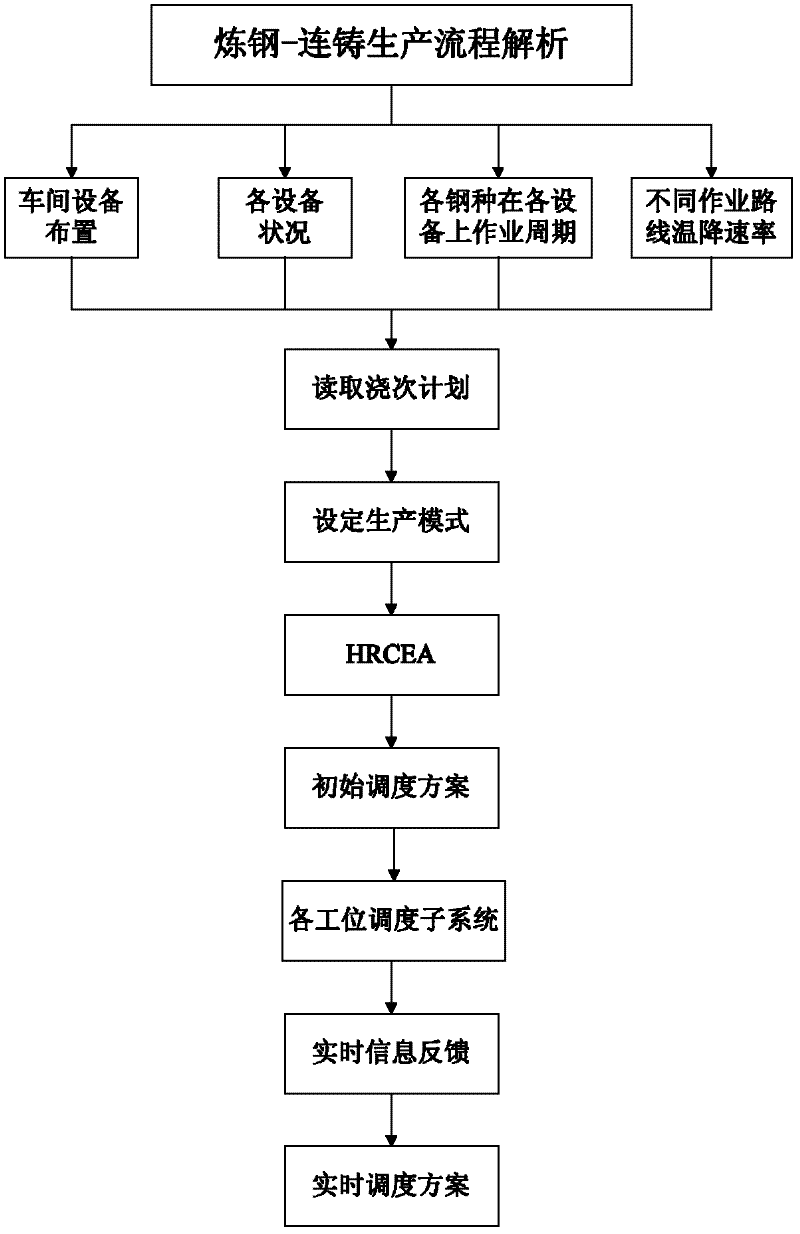

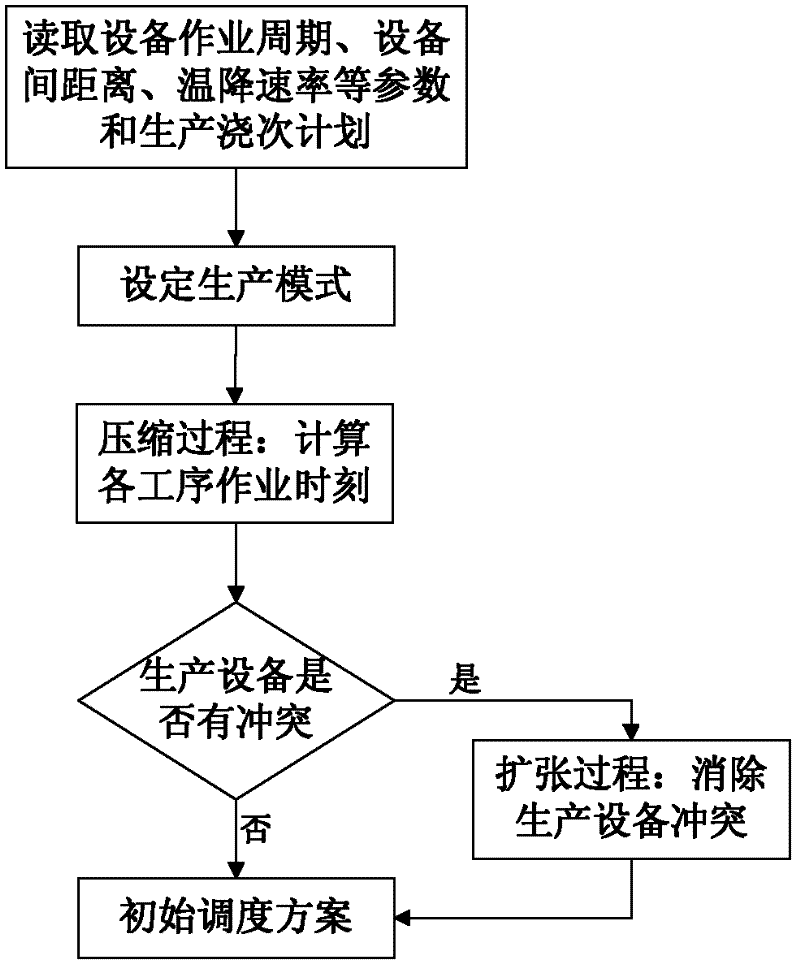

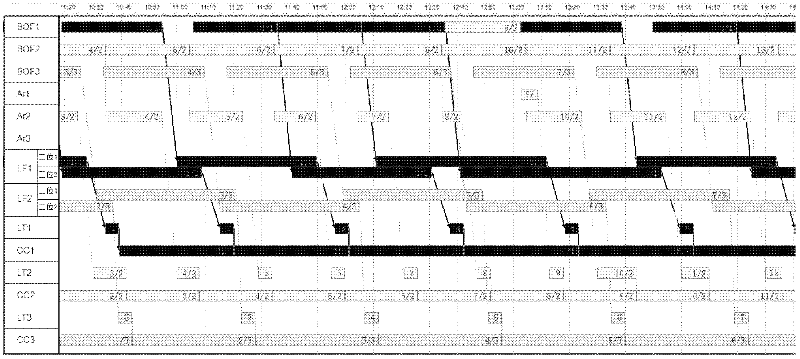

[0092] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0093] Steelmaking-continuous casting production scheduling in steel mills refers to determining the start-up time of each pouring plan on the corresponding continuous casting machine and the start and end time of each furnace plan on the corresponding equipment according to the production plan, that is, the production scheduling plan; at the same time , Execute the production scheduling plan and reschedule it according to the uncertain factors in the actual production process. The scheduling implementation process designed by the present invention includes analyzing the production process, establishing a scheduling model, designing a solution algorithm, and realizing dynamic scheduling, such as figure 1 shown.

[0094] The core of the present invention is to establish a steelmaking-continuous casting production scheduling model with the goal of shortening the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com