Tungsten crucible double-sleeve hoisting frame

A double-sleeve, hoisting frame technology, applied in the direction of single crystal growth, crystal growth, polycrystalline material growth, etc., can solve the problems of crucible falling off and breaking, tungsten crucible is highly brittle, easy to be crushed, etc., to achieve long-term reliable work, The effect of precise positioning control and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

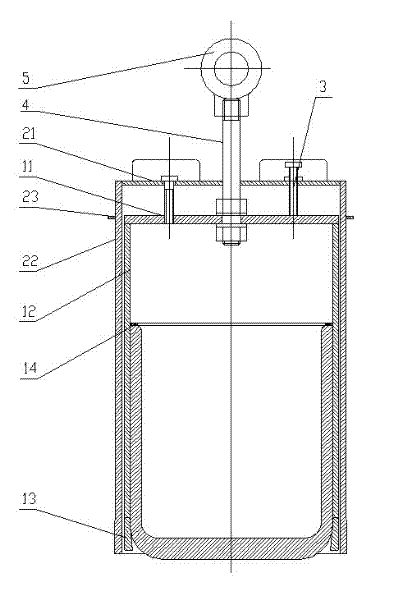

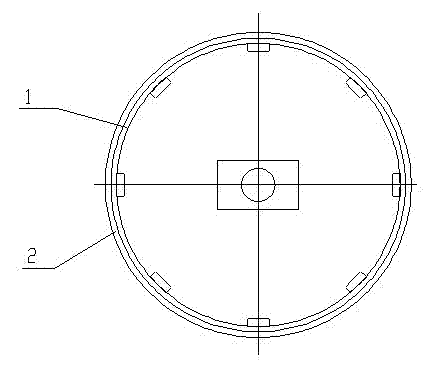

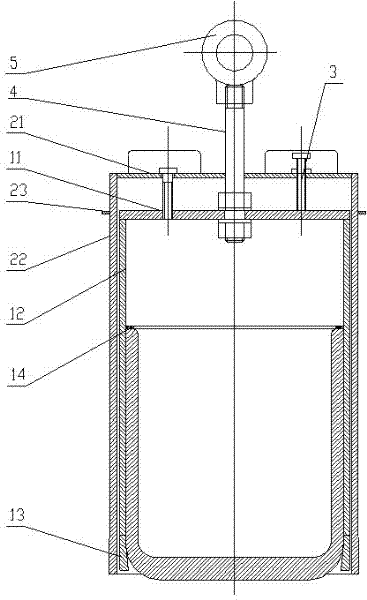

[0029] see figure 1 , a tungsten crucible double-sleeve hoisting frame related to the present invention, including an inner sleeve 1 and an outer sleeve 2, the outer sleeve 2 is placed outside the inner sleeve 1, and the inner sleeve 1 includes eight pieces Arranged on the arc plate 12 on the same circumference and the lifting plate 11 connected to the top of the arc plate 12, the arc plate 12 is 2mm thick and 40mm wide, and the bottom of the arc plate 12 is provided with There is an inward hook 13, in order to ensure that the hook 13 accurately extends into the bottom arc area of the tungsten crucible, an inner sleeve positioning ring 14 is welded on the upper inner wall of the arc plate 12, and the outer sleeve 2 includes The cylinder 22 and the support plate 21 fixedly connected to the top of the cylinder 22, the cylinder 22 is 2.5mm thick, and also for the convenience of positioning when the bottom of the tungsten crucible cannot be seen, the outer wall of the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com