Climbing film type multi-effect water distillator

A technology of distilled water machine and membrane evaporator, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve the problem of increasing energy consumption, increasing steam consumption, and large equipment structure and other problems, to achieve the effect of accelerating condensation, increasing yield, and evenly distributing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

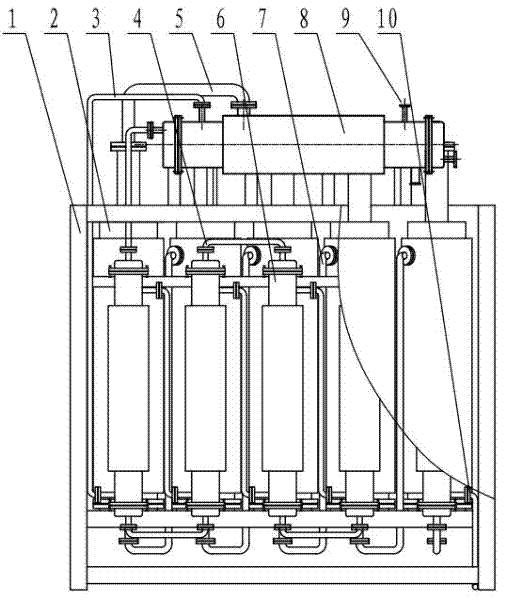

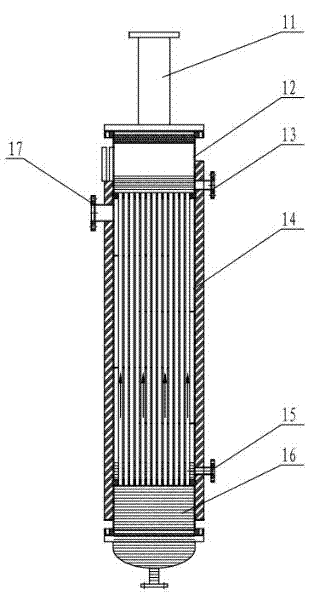

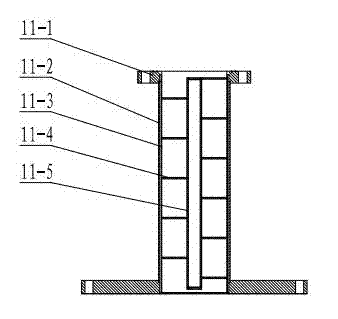

[0024] According to attached figure 1 It can be seen that the present invention specifically relates to a rising-film multi-effect distilled water machine, comprising a frame 1, on which an evaporator 2 sequentially connected through a raw water pipeline 4 is arranged, and a condensing device 8 is arranged above the evaporator 2, and the condensing device 8 is arranged on the top of the evaporator 2, and The device 8 and the evaporator 2 are connected to the preheater 6 through the pure steam pipeline 5 and the injection water pipeline 3, and the feed water inlet of the evaporator 2 is connected to the preheater 6, and the evaporator 2 is a rising film evaporator, The structure of the rising film evaporator is divided into four sections. From top to bottom, it is the steam-water separation section 11, the reflux defoaming section 12, the evaporation section 14 and the water storage chamber 16. The evaporation section 14 is equipped with longitudinally arranged The evaporating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com