Preparation method of metal-semiconductor electromagnetic wave absorption type nano composite material

A nanocomposite material and technology of composite materials, applied in the field of electromagnetic wave absorbing materials, can solve the problem that nanocomposite materials do not have multiple resonance absorption, and achieve the effects of being beneficial to large-scale industrial production, simple process and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First, in the glove box, 65wt% of analytically pure iron oxide, 35wt% of analytically pure titanium powder, and about 10% of the total weight of the former two TiO 2 Put the powder and stainless steel balls into a ball mill tank, take it out from the glove box after sealing, and mill it in a high-energy ball mill for 30 hours. The mass ratio of stainless steel balls to raw materials in the ball mill is 15-20, and perform a mechanochemical reaction; Place in a vacuum annealing furnace and anneal at 950°C for 30 minutes. The atmosphere in the annealing furnace and the ball milling tank is argon, which protects the iron nanoparticles from being oxidized by air at high temperature.

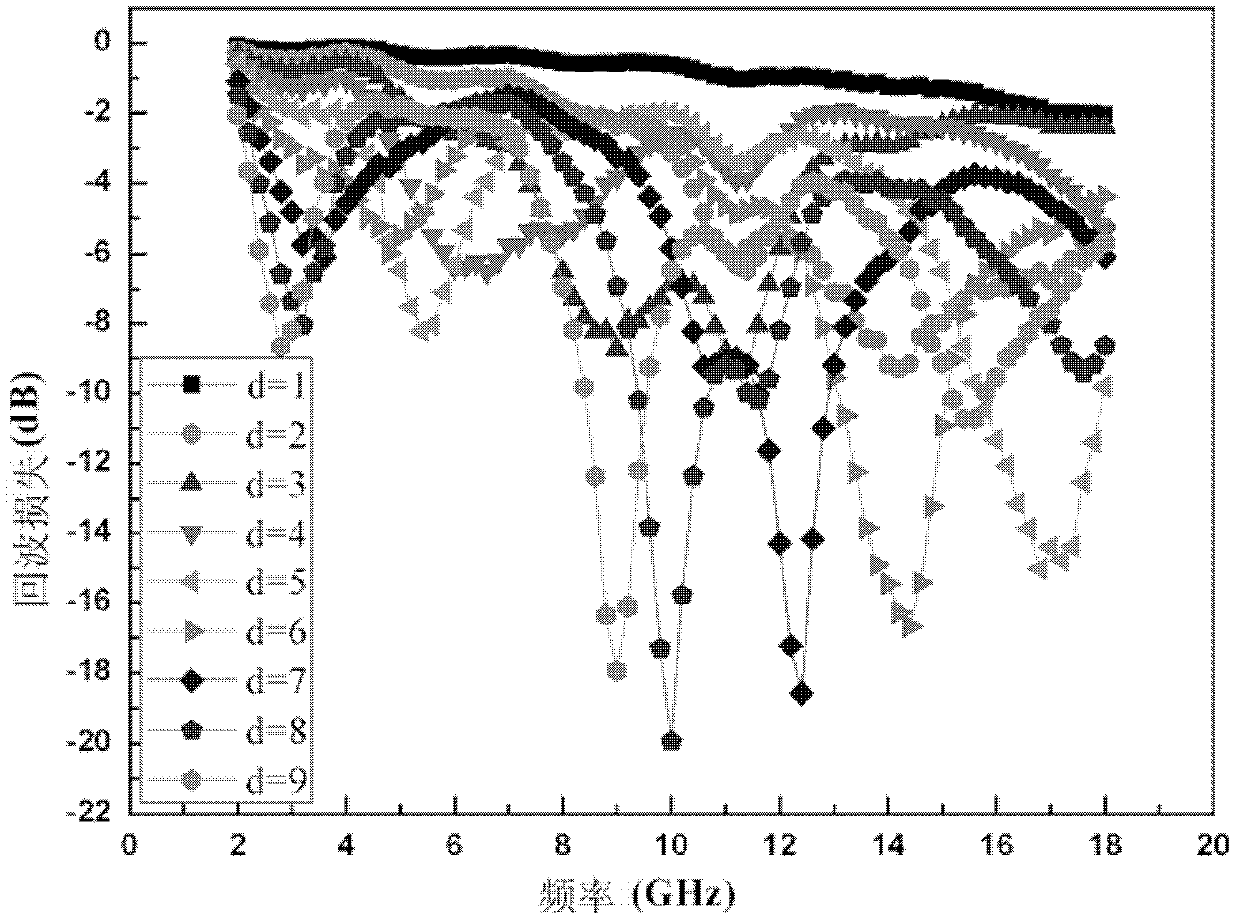

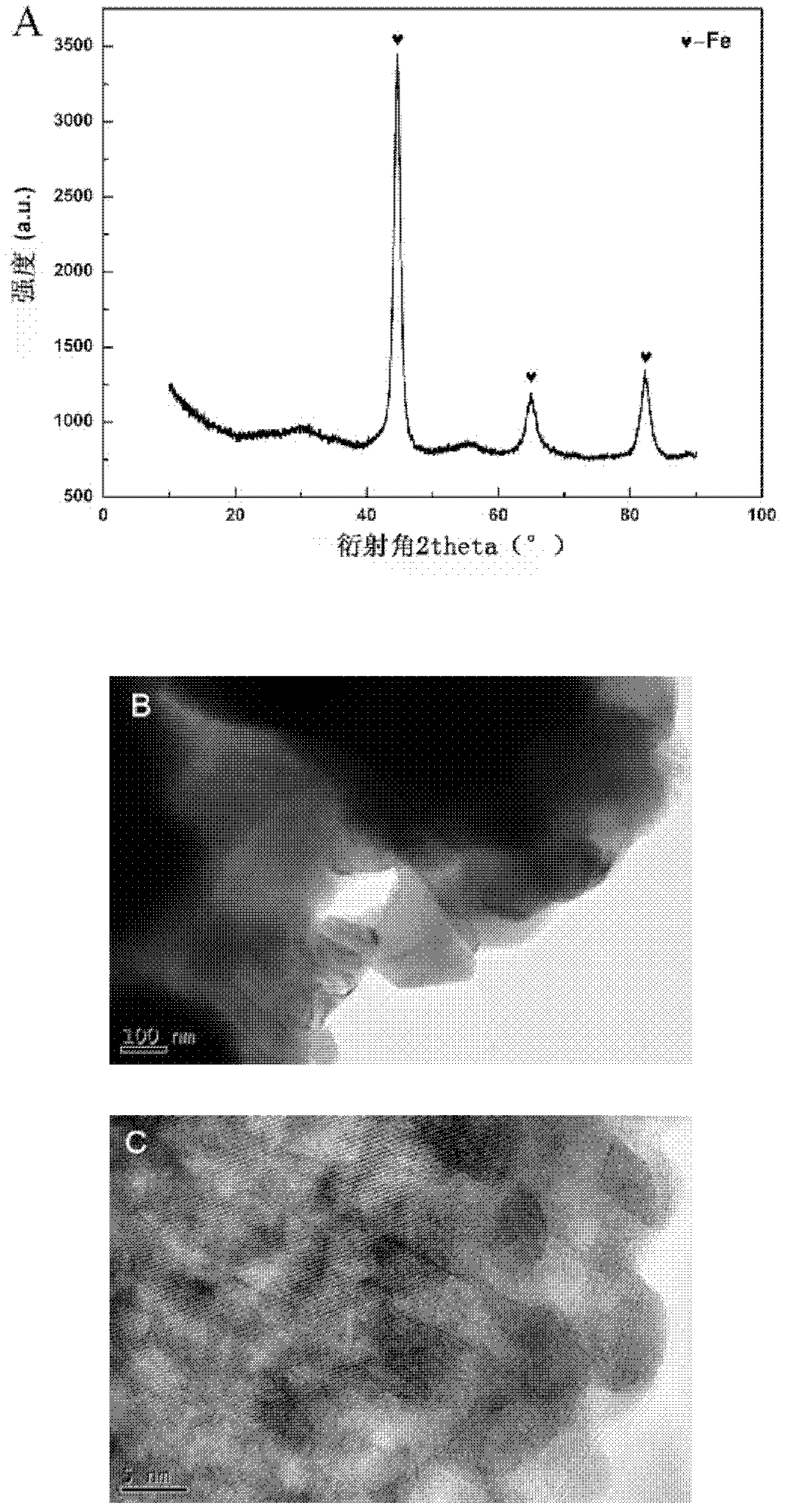

[0030] After the sample was cooled to room temperature (morphology as figure 1 shown), the electromagnetic properties of the sample were tested with an Agilent8722ES network analyzer, and the results are as follows figure 2 shown. Among them, TiO 2 The function of the powder is to lower the...

Embodiment 2

[0033] In the glove box, 63wt% of analytically pure iron oxide, 37wt% of analytically pure titanium powder, and about 10% of the total weight of the former two TiO 2 Put the powder and stainless steel balls into a ball mill jar, take it out from the glove box after sealing, and mill it in a high-energy ball mill for 40 hours. The mass ratio of stainless steel balls and raw materials in the ball mill is 15-20, and carry out mechanochemical reaction; Place in a vacuum annealing furnace and anneal at 350°C for 50 minutes. The atmosphere in the annealing furnace and the ball milling tank is argon, which protects the iron nanoparticles from being oxidized by air at high temperature.

[0034] After the sample was cooled to room temperature (morphology as image 3 shown), the electromagnetic properties of the sample were tested with an Agilent8722ES network analyzer, and the results are as follows Figure 4 shown. This embodiment obtains the metal-semiconductor type electromagnetic...

Embodiment 3

[0037] First, in the glove box, 64wt% of analytically pure iron oxide, 36wt% of analytically pure titanium powder, and about 12% of the total weight of the former two TiO 2Put the powder and stainless steel balls into a ball mill jar, take it out from the glove box after sealing, and mill it in a high-energy ball mill for 35 hours. The mass ratio of stainless steel balls to raw materials in the ball mill is 15-20, and carry out mechanochemical reaction; Place in a vacuum annealing furnace and anneal at 800°C for 40 minutes. The atmosphere in the annealing furnace and the ball milling tank is argon, which protects the iron nanoparticles from being oxidized by air at high temperature.

[0038] This embodiment obtains the metal-semiconductor type electromagnetic wave absorbing nanocomposite material, and its structure and performance are as follows: The gained composite material is Fe / TiO 2 , the two phases are closely connected, in which the average grain size of Fe is about 35-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com