Plunger pneumatic quick-change coupler

A technology of plunger type and head, which is applied in the field of quick connection of gas pipelines, can solve the problems of many parts, large radial size, and short service life, and achieves improved service life, small radial size, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

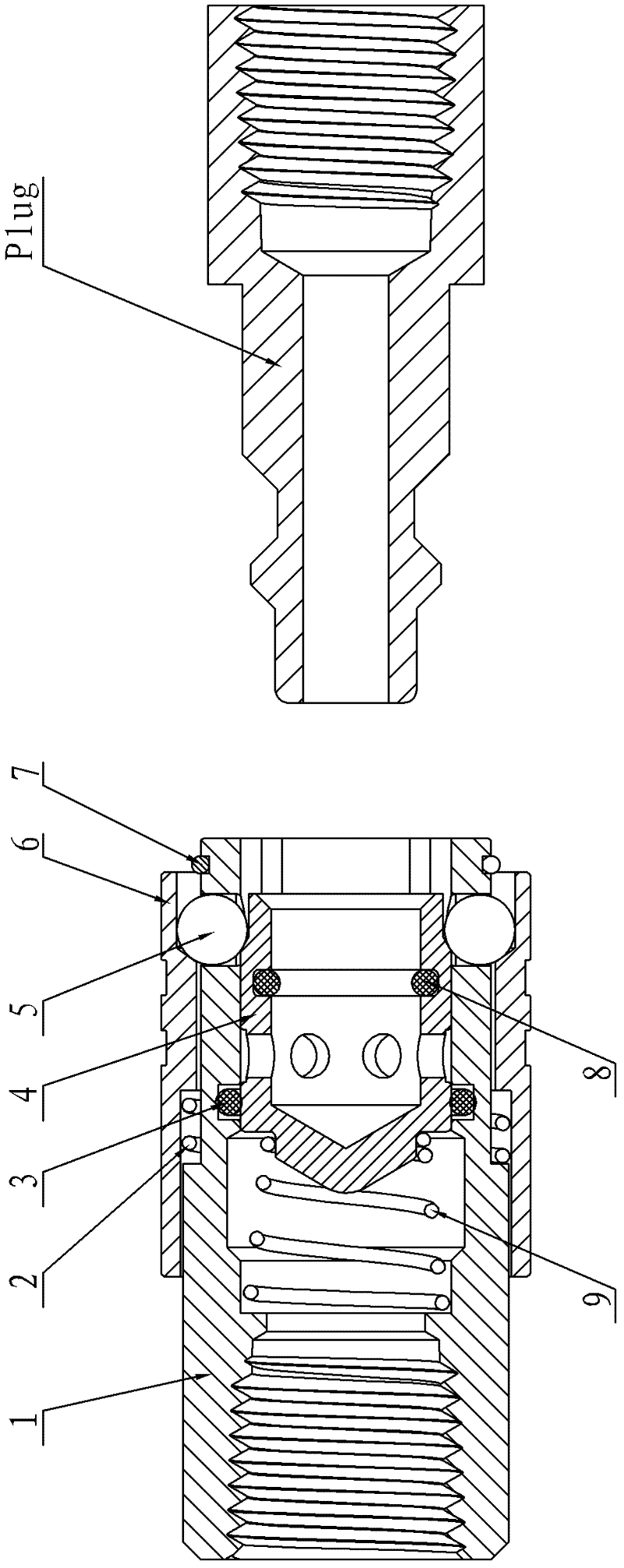

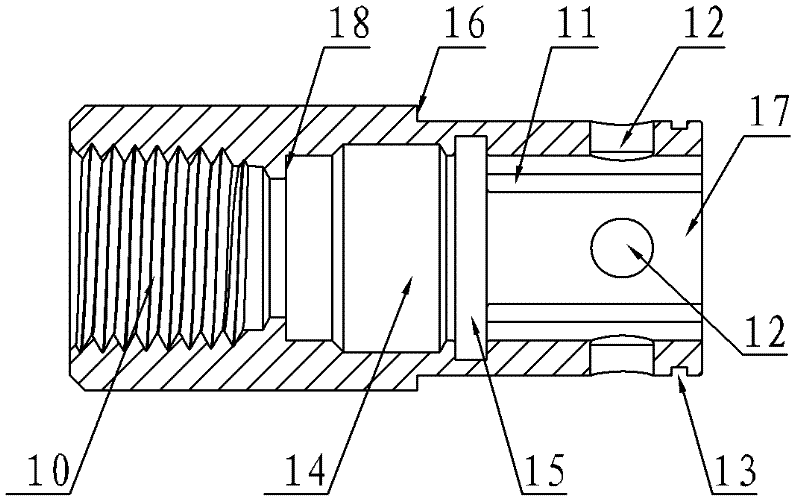

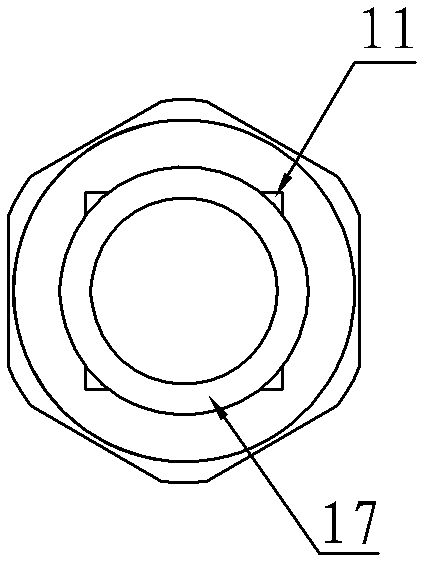

[0024] Embodiment 1: A kind of plunger type pneumatic quick-change joint, such as figure 1 As shown, it includes intake joint 1, sliding sleeve spring 2, intake sealing ring 3, valve core 4, locking steel ball 5, moving sliding sleeve 6, sliding sleeve limiter 7, air outlet sealing ring 8 and valve core Spring 9, the sliding sleeve limiter 7 is a retaining ring for the shaft; the air intake sleeve 1 is a sleeve structure, such as figure 2 , image 3 As shown, the left section is the connecting section, and the right section is the matching section. Four pressure relief grooves 11 are uniformly arranged in the circumferential direction on the inner hole wall of the matching section of the intake joint 1. The function of the pressure relief grooves 11 is When the air-inducing plug Plug is inserted, it produces a pressure relief effect, which is more conducive to the easy insertion of the air-inducing plug Plug. Four locking steel ball holes 12 are evenly arranged on the outer ...

Embodiment 2

[0025] Embodiment 2: A kind of plunger type pneumatic quick-change joint, such as Figure 6 As shown, its structure is similar to that of Embodiment 1, the difference is that the sliding sleeve limiter 7 set between the moving sliding sleeve 6 and the intake joint 1 is changed from a shaft retaining ring to a stepped shaft with a shaft shoulder In this example, the inner hole of the stepped bushing fits with the outer circle of the right end of the air intake sleeve 1, and the two are fixedly connected. A protective step is provided at the right end of the stepped bushing. The outer diameter of the protective step is in line with the movement The maximum external diameter of sliding sleeve 6 right ends is identical. The function of the stepped sleeve can not only limit the axial position of the movable sliding sleeve 6, but also prevent the operator from directly touching the movable sliding sleeve 6 during the working process, so that the movable sliding sleeve 6 can move to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com