Method for preparing SmS thin film by solvothermal method

A solvothermal method, a thin-film technology, applied in chemical instruments and methods, solutions of liquid solvents at room temperature, and single crystal growth, etc., can solve the problems of difficult process control, expensive equipment, and high cost, improve the quality of the film, avoid Curl, good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

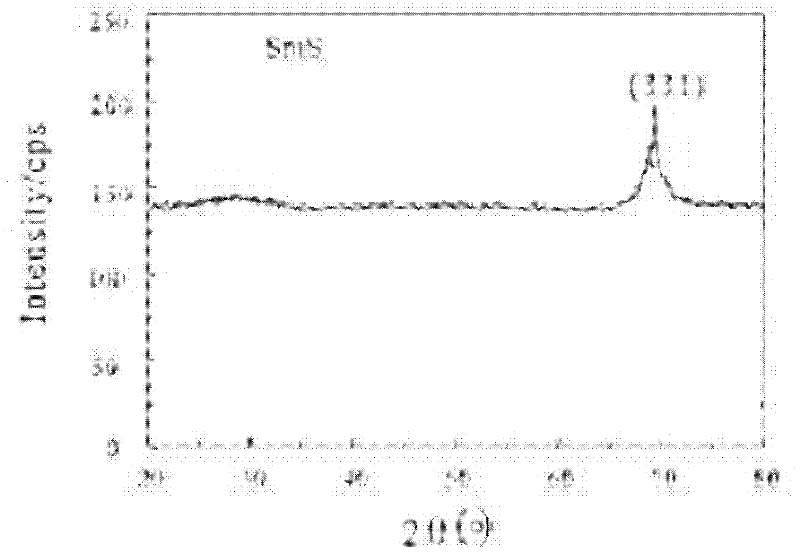

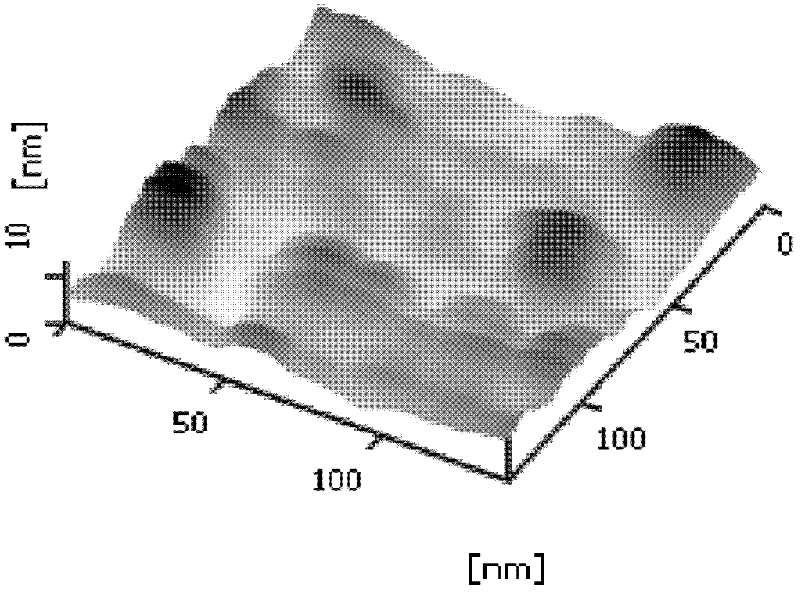

Image

Examples

Embodiment 1

[0019] Example 1: Step 1: Introducing Ar gas into deionized water to remove O in water 2 ;

[0020] Step two: the analytically pure SmCl 3 ·6H 2 O is dissolved in deionized water with Ar gas and configured as SmCl with a concentration of 0.03mol / L 3 Solution, labeled A;

[0021] Analytical pure thioacetamide (H 3 CCSNH 2 ) was dissolved in absolute ethanol, and configured as a 0.2mol / L ethanol solution of thioacetamide, marked as B;

[0022] Step 3: Mix solutions A and B according to the volume ratio of 2:1 and stir evenly, adjust the pH value to 2.00 with 0.05mol / L HCl solution, and mark it as C;

[0023] Step 4: Pour solution C into the hydrothermal kettle, control the filling degree at 50%, put the cleaned substrate, seal the hydrothermal kettle, put it into the DHG-9075A electric vacuum drying oven, control the water The heat temperature is 120°C and the pressure is 20MPa for 48 hours;

[0024] Step 5: Cool down to room temperature naturally after the reaction, tur...

Embodiment 2

[0025] Example 2: Step 1: Introducing Ar gas into deionized water to remove O in water 2 ;

[0026] Step two: the analytically pure SmCl 3 ·6H 2 O is dissolved in deionized water fed with Ar gas to form SmCl with a concentration of 0.06mol / L 3 Solution, labeled A;

[0027] Analytical pure thioacetamide (H 3 CCSNH 2) is dissolved in absolute ethanol, and is configured into a 0.3mol / L ethanol solution of thioacetamide, marked as B;

[0028] Step 3: Mix and stir solutions A and B evenly according to the volume ratio of 1:6, adjust the pH value to 2.40 with 0.05mol / L HCl solution, and mark it as C;

[0029] Step 4: Pour solution C into the hydrothermal kettle, control the filling degree at 52%, put the cleaned substrate, seal the hydrothermal kettle, put it into the DHG-9075A electric vacuum drying oven, control the water The heat temperature is 150°C and the pressure is 10MPa for 30 hours;

[0030] Step 5: Cool down to room temperature naturally after the reaction, turn o...

Embodiment 3

[0031] Example 3: Step 1: Introducing Ar gas into deionized water to remove O in water 2 ;

[0032] Step two: the analytically pure SmCl 3 ·6H 2 O is dissolved in deionized water filled with Ar gas, and configured as SmCl with a concentration of 0.2mol / L 3 Solution, labeled A;

[0033] Analytical pure thioacetamide (H 3 CCSNH 2 ) was dissolved in absolute ethanol, and configured as a 0.03mol / L ethanol solution of thioacetamide, marked as B;

[0034] Step 3: Mix solutions A and B according to the volume ratio of 1:3 and stir evenly, adjust the pH value to 2.80 with 0.05mol / L HCl solution, and mark it as C;

[0035] Step 4: Pour solution C into the hydrothermal kettle, control the filling degree at 58%, put the cleaned substrate, seal the hydrothermal kettle, put it into the DHG-9075A electric vacuum drying oven, control the water The heat temperature is 130°C and the pressure is 15MPa for 40 hours;

[0036] Step 5: Cool down to room temperature naturally after the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com