Shape memory alloy sealing gasket and production technology thereof

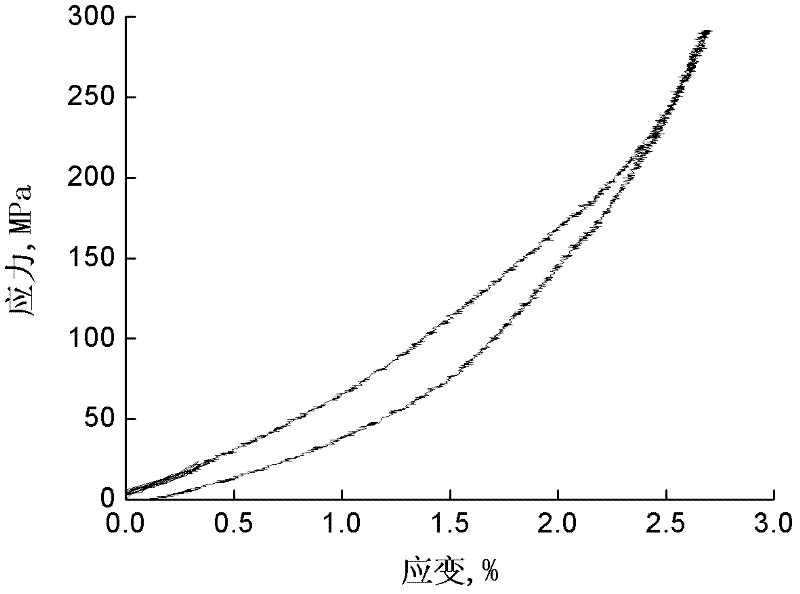

A technology for sealing gaskets and memory alloys, which is applied in flange connections, pipes/pipe joints/fittings, passing components, etc., can solve the problem that the stress-strain curve does not show a phase transition platform, and optimize the manufacturing process of unsealed gaskets Or in-depth research, performance impact and other issues to achieve the effect of ensuring long-term sealing effect, high pressure and prolonging the life of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

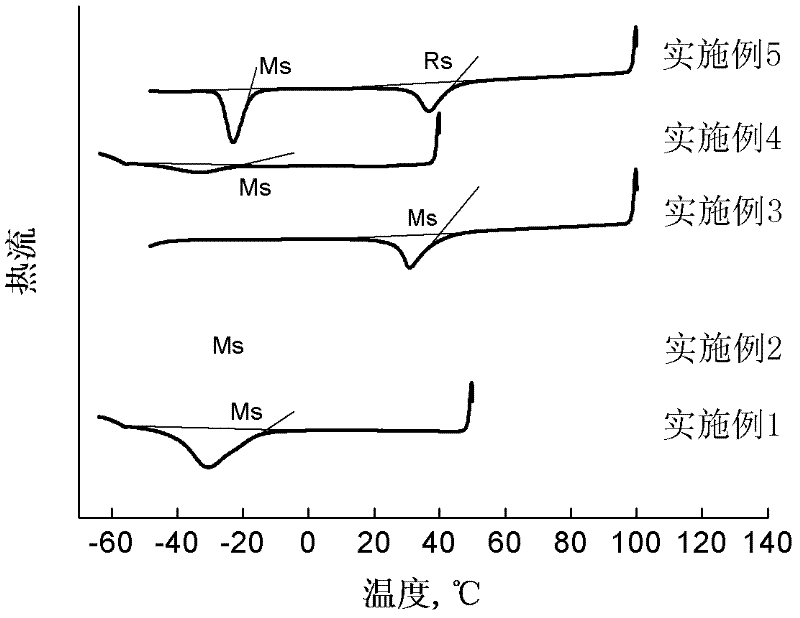

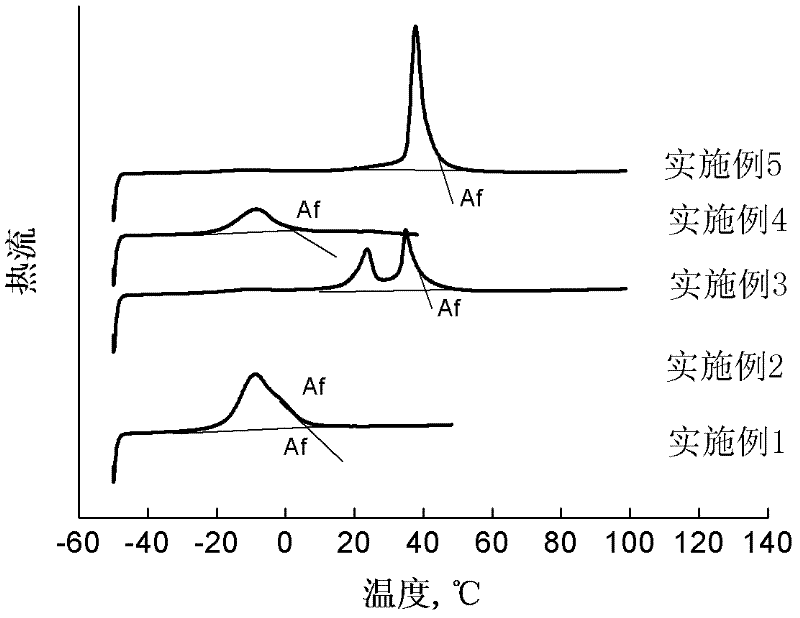

Embodiment 1

[0032] The composition of the material in the present invention is as follows: Ni-58.25, Ti-41.45, Al-0.168, Cu-0.0256, V-0.106.

[0033] Production technology of the present invention is as follows:

[0034] (1) Prepare to be hot-rolled into a plate, the composition of the plate is as required above, and the thickness of the plate material is about 2mm;

[0035] (2) According to the size requirements of the gasket in the ASME B16.47 standard, cut the plate wire into a flat gasket with an inner diameter of 48mm and an outer diameter of 52.12mm, and grind both sides to 1.45mm;

[0036] (3) Solid solution treatment of the gasket: heat preservation at 850°C for 30 minutes;

[0037] (4) Perform superelastic training on the gasket, in which the aging temperature is 250°C and the duration is 60 minutes;

[0038] (5) Clean the surface of the gasket and put it into use.

Embodiment 2

[0040] The composition of the material in the present invention is as follows: Ni-58.25, Ti-41.45, Al-0.168, Cu-0.0256, V-0.106.

[0041] Production technology of the present invention is as follows:

[0042] (1) Prepare to be hot-rolled into a plate, the composition of the plate is as required above, and the thickness of the plate material is about 2mm;

[0043] (2) According to the size requirements of the gasket in the ASME B16.47 standard, cut the plate wire into a flat gasket with an inner diameter of 48mm and an outer diameter of 52.12mm, and grind both sides to 1.45mm;

[0044] (3) Solid solution treatment of the gasket: heat preservation at 850°C for 30 minutes;

[0045] (4) Perform superelastic training on the gasket, wherein the pre-deformation rate is 0.2%, the aging temperature is 250°C, and the duration is 180min;

[0046] (5) Clean the surface of the gasket and put it into use.

Embodiment 3

[0048] The composition of the material in the present invention is as follows: Ni-58.25, Ti-41.45, Al-0.168, Cu-0.0256, V-0.106.

[0049] Production technology of the present invention is as follows:

[0050] (1) Prepare to be hot-rolled into a plate, the composition of the plate is as required above, and the thickness of the plate material is about 2mm;

[0051] (2) According to the size requirements of the gasket in the ASME B16.47 standard, cut the plate wire into a flat gasket with an inner diameter of 48mm and an outer diameter of 52.12mm, and grind both sides to 1.45mm;

[0052] (3) Solid solution treatment of the gasket: heat preservation at 850°C for 30 minutes;

[0053] (4) Perform superelastic training on the gasket, in which the pre-deformation rate is 0.2%, the aging temperature is 400°C, and the duration is 60 minutes;

[0054] (5) Clean the surface of the gasket and put it into use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com