Method for preparing semisolid alloy through centrifuging and chilling

A semi-solid and semi-solid slurry technology, which is applied in the field of centrifugal chilling to prepare semi-solid alloys, can solve the problems of short service life of the mixing chamber and stirring rods, which have not yet been put into industrial production, and affect the uniformity of the slurry. Remarkable refinement effect, flexible production mode, and the effect of avoiding air suction and slag inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

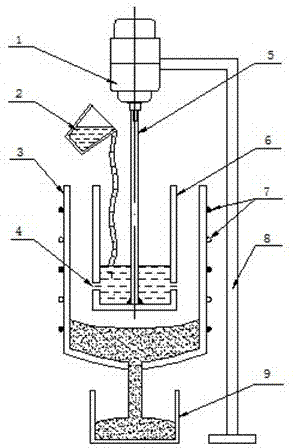

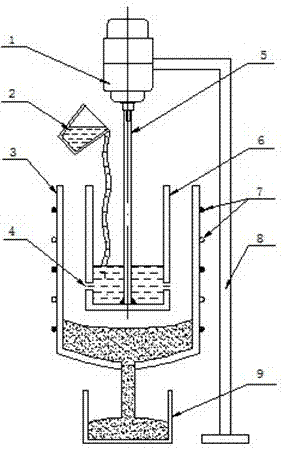

Method used

Image

Examples

Embodiment 1

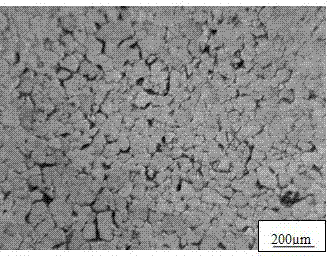

[0030] Example 1: Melt the commercial ZL203 alloy, and preheat the chilled bucket and centrifugal bucket to 250°C and 600°C respectively; when the melt temperature drops to 700°C, pour it into the centrifugal bucket, turn on the motor, and adjust the centrifugal Rotate to 1000r / min to prepare semi-solid alloy. The prepared slurry was collected in a crucible and cooled to room temperature. Depend on figure 2 It can be seen that the microstructure of the ingot prepared by the centrifugal chilling method is a fine, uniform granular non-dendritic structure.

Embodiment 2

[0031] Example 2: Melt the AZ91D magnesium alloy, preheat the chilled barrel to 230°C, and preheat the centrifugal barrel to 600°C; when the temperature of the melt drops to 680°C, pour it into the centrifugal barrel, turn on the speed regulating motor, and adjust The rotation speed was 800r / min, and the collected slurry was collected in a crucible and then cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com