Preparation method of water-expandable single-component polyurethane sealant

A polyurethane sealant, water-swellable technology, applied in polyurea/polyurethane adhesives, chemical instruments and methods, adhesives, etc., can solve the problems of slow water absorption rate, low expansion rate, slow expansion rate, etc., to achieve bonding The effect of good performance, adjustable expansion ratio and excellent expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

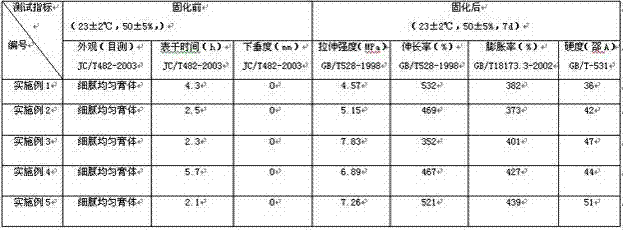

Examples

Embodiment 1

[0058] A preparation method for water-swellable one-component polyurethane sealant, comprising the following steps:

[0059] Step 1: Preparation of water-swellable polyurethane prepolymer: 600 g of difunctional ethylene oxide and propylene oxide copolymerized diol with a molecular weight of 2000 and polyoxypropylene triol with a molecular weight of 1000 Add 30g into the reaction kettle, stir and adjust the temperature of the reaction kettle to 100°C. After mixing evenly, remove water for 2.5h under the condition of vacuum degree of 0.095Mpa, and lower the temperature to 80°C. After the temperature is constant, add to the reaction Add 181.2 g of diphenylmethane-4,4'-diisocyanate and 0.001% of dibutyltin dilaurate to the total mass of the above mixture, and react for 2.5 hours to obtain a water-swellable polyurethane prepolymer.

[0060] Step 2: Preparation of water-swellable one-component polyurethane sealant: combine 550 g of the prepared water-swellable polyurethane prepolyme...

Embodiment 2

[0062] A preparation method for water-swellable one-component polyurethane sealant, comprising the following steps:

[0063] Step 1, preparation of water-swellable polyurethane prepolymer: 500 g of polyoxyethylene polyol with a molecular weight of 2000 and 125 g of trifunctional polyoxypropylene triol with a molecular weight of 5000 are added to the reactor, stirred and adjusted for reaction The temperature of the kettle is 110°C. After mixing evenly, remove water for 2.0 hours under the condition of a vacuum of 0.097Mpa, and cool down to 65°C. After the temperature is constant, add 145.2g of diphenylmethane-4 , 4'-diisocyanate, and stannous octoate accounting for 0.002% of the total mass of the above mixture, after reacting for 3.0 hours, a water-swellable polyurethane prepolymer was obtained.

[0064] Step 2, preparation of water-swellable one-component polyurethane sealant: 300 g of the prepared water-swellable polyurethane prepolymer, 200 g of diisodecyl phthalate, 379 g o...

Embodiment 3

[0066] A preparation method for water-swellable one-component polyurethane sealant, comprising the following steps:

[0067] Step 1, preparation of water-swellable polyurethane prepolymer: 600 g of ethylene oxide and tetrahydrofuran copolymerized glycol with a molecular weight of 5000 and 120 g of trifunctional polyoxypropylene triol with a molecular weight of 3000 are added to the reactor, and stirred And adjust the temperature of the reaction kettle to 95°C. After mixing evenly, remove water for 4.5 hours under the condition of vacuum degree of 0.094Mpa, and lower the temperature to 75°C. After the temperature is constant, add 68.9g of toluene diisocyanate to the reaction kettle , and stannous octoate accounting for 0.005% of the total mass of the above mixture, after reacting for 4.5 hours, a water-swellable polyurethane prepolymer was obtained.

[0068] Step 2: Preparation of water-swellable one-component polyurethane sealant: combine 450 g of the prepared water-swellable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com