Construction method for improving fatigue strength of welding joint of orthotropic steel bridge deck

A steel bridge deck, orthotropic technology, used in welding equipment, welding equipment, welding accessories, etc., can solve the problem of uncontrollable fatigue cracks, achieve stable and reliable quality of remelted welds, and reduce uncontrollable human interference factors. , easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

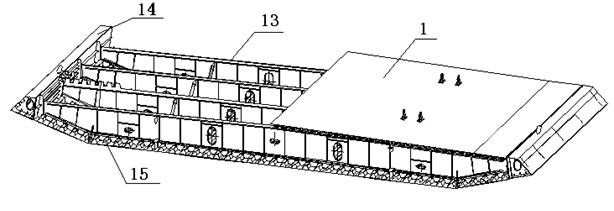

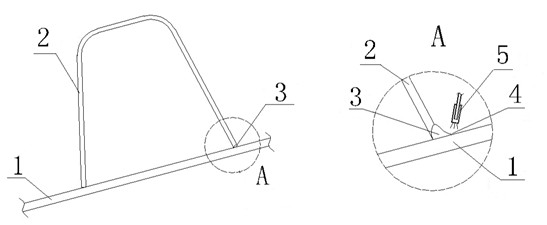

[0034] Embodiment 1: construction method of the present invention is applied in bridge construction, and the typical structure of the orthotropic steel bridge that the present invention is aimed at is as figure 1 As shown, the structures involved in the bridge construction include a bridge deck 1 , a diaphragm 13 , an air nozzle 14 , and a bridge bottom plate 15 . The implementation site of the tungsten argon arc welding remelting process without welding wire described in the present invention is the longitudinal connection fillet weld 3 between the U-shaped longitudinal rib 2 of the orthotropic steel bridge and the bridge deck 1, see figure 2 , figure 2 The picture on the right in the middle is the enlarged weld 3, weld toe 4 and argon tungsten arc welding torch 5.

[0035] A construction method for improving the fatigue strength of welded joints of orthotropic steel bridge decks of the present invention is constructed according to the following steps:

[0036] (1) Prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com