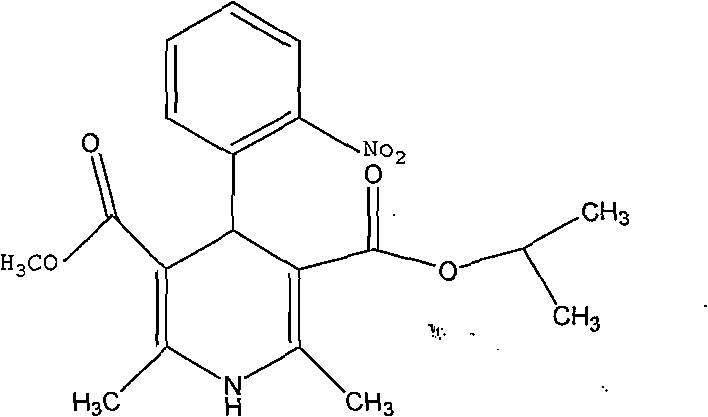

Nisoldipine liposome solid preparation

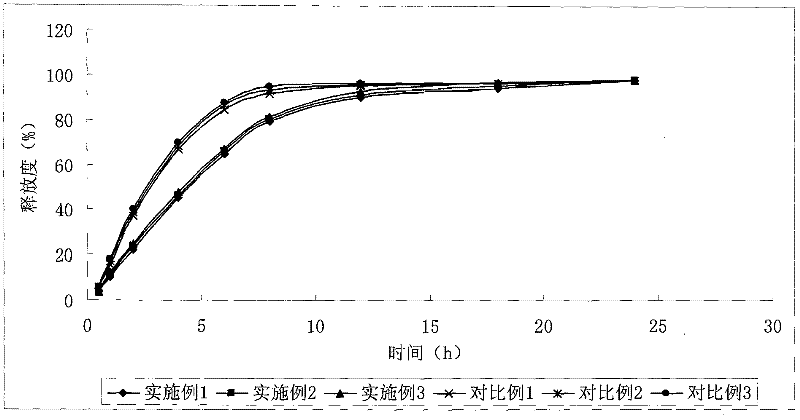

A solid preparation, dipine fat technology, applied in the field of medicine, can solve the problems of low bioavailability, long dissolution time, many times of taking medicine, etc., and achieve the effects of high bioavailability, good sustained-release effect, and excellent dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Example 1 Nisoldipine liposome tablet

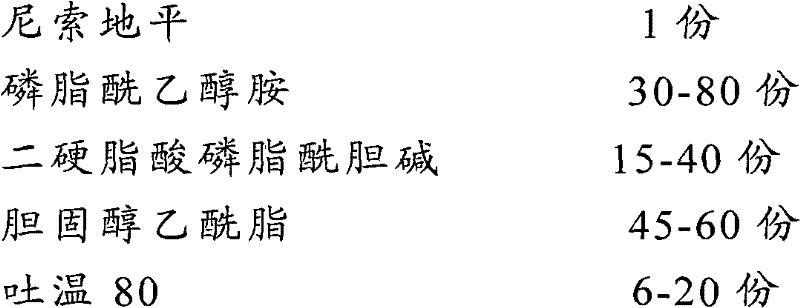

[0078] The raw and auxiliary materials used are as follows:

[0079]

[0080] Adopt following production process to prepare nisoldipine liposome tablet:

[0081] (1) Accurately weigh 5g nisoldipine, 200g phosphatidylethanolamine, 100g phosphatidylcholine distearate, 230g cholesterol acetyl ester, 50g Tween 80, dissolve in 1200ml volume ratio of dichloromethane and In a mixed solvent of isopropanol, stir to dissolve;

[0082] (2) Place the above solution in an eggplant-shaped bottle, remove methylene chloride and isopropanol under reduced pressure in a 45°C water bath, and form a uniform transparent film on the wall of the bottle;

[0083] (3) Add 1200ml of phosphate buffer solution with a pH value of 7.0 to the eggplant-shaped bottle, and continue to rotate in a water bath at 45°C under normal pressure to swell and hydrate the film;

[0084] (4) The above solution is filtered with a 0.45 μm microporous membrane, the filtrate...

Embodiment 2

[0088] Example 2 Nisoldipine liposome tablet

[0089] The raw and auxiliary materials used are as follows:

[0090]

[0091] Adopt following production process to prepare nisoldipine liposome tablet:

[0092] (1) Accurately weigh 10g nisoldipine, 300g phosphatidylethanolamine, 150g phosphatidylcholine distearate, 225g cholesterol acetyl ester, 80g Tween 80, dissolve in 1500ml volume ratio of dichloromethane and In a mixed solvent of isopropanol, stir to dissolve;

[0093] (2) Place the above solution in an eggplant-shaped bottle, remove methylene chloride and isopropanol under reduced pressure in a 45°C water bath, and form a uniform transparent film on the wall of the bottle;

[0094] (3) Add 1500ml of phosphate buffer solution with a pH value of 7.0 to the eggplant-shaped bottle, and continue to rotate in a 45°C water bath under normal pressure to swell and hydrate the film;

[0095] (4) The above solution is filtered with a 0.45 μm microporous membrane, the filtrate...

Embodiment 3

[0099] Example 3 Nisoldipine liposome capsules

[0100] The raw and auxiliary materials used are as follows:

[0101]

[0102]

[0103] Adopt following production process to prepare nisoldipine liposome capsules:

[0104] (1) Accurately weigh 10g nisoldipine, 300g phosphatidylethanolamine, 150g phosphatidylcholine distearate, 250g cholesterol acetyl ester, 120g Tween 80 and dissolve in 2000ml volume ratio of 2:1 dichloromethane and iso In the mixed solvent of propanol, stir to make it dissolve;

[0105] (2) Place the above solution in an eggplant-shaped bottle, remove methylene chloride and isopropanol under reduced pressure in a 45°C water bath, and form a uniform transparent film on the wall of the bottle;

[0106] (3) Add 2000ml of phosphate buffer solution with a pH value of 7.0 to the eggplant-shaped bottle, and continue to rotate in a water bath at 45°C under normal pressure to swell and hydrate the film;

[0107] (4) The above solution is filtered with a 0.45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com