Vibration tobacco stem sorting machine

A vibrating, finishing machine technology, applied in the direction of tobacco, tobacco processing, conveyor objects, etc., can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

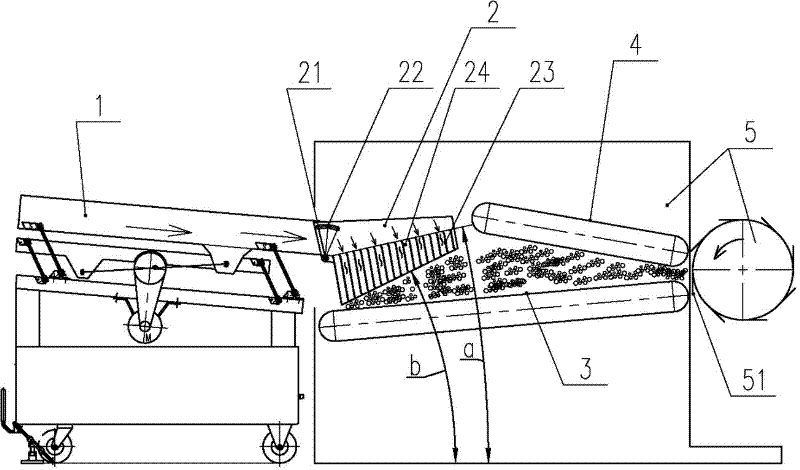

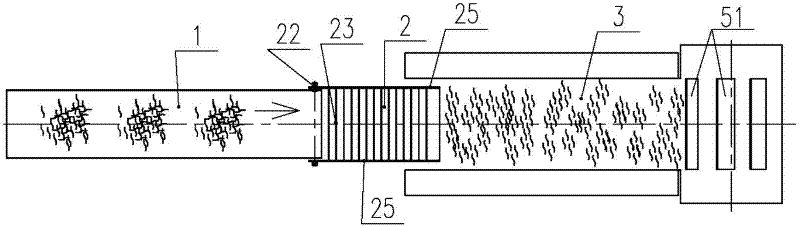

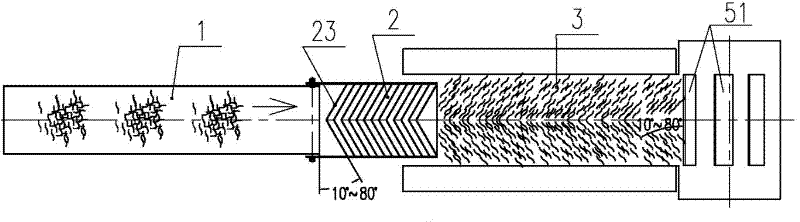

[0017] As shown in the figure, the present invention includes a vibrating conveying trough body 1 and a vibrating grid type chute 2 connected in sequence. Between the feeding ends of the row chain 3; the vibrating grating chute 2 is formed by connecting the separators 23 arranged at continuous equal intervals or gradually widening along the material flow direction to the side plates 25 on both sides, and the separators 23 and the two sides The side plates 25 separate and form continuous grid drains 24 . The upper edges of the continuously arranged partitions 23 rise block by block along the material flow direction to form a warping head on the top surface. The head-up angle a of the warping head on the top surface is 0-25°. The lower edges of the continuously arranged partitions 23 are also raised block by block along the material flow direction to form warps on the bottom. The head-up angle b of the warping head on the bottom surface is 5-45°. The separator 23 of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com