Small molecule polypeptide Ca-chelate of fishbone and preparation method

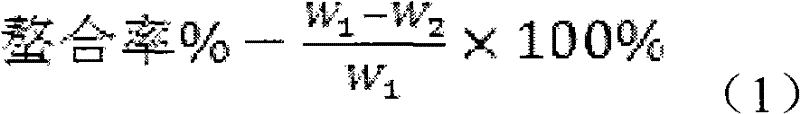

A small molecule polypeptide, chelated calcium technology, applied in food preparation, application, food science and other directions, can solve the problem of calcium absorption effect and application scope limitation, no reports of fish bone small molecule polypeptide chelated calcium powder, etc. The preparation method is simple and feasible, the cost is low, and the calcium chelation rate is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 fishbone small molecule polypeptide chelated calcium powder

[0031] (1) Take 1,000 grams of flounder bones, thaw, remove the residual fish meat on the surface, wash, cook the fish bones for 20 minutes at a pressure of 0.165Mpa and a temperature of 120°C, and then use a tissue masher at 12,000 rpm Beat, cool, and drain to obtain 380 grams of fish bone paste, freeze to -10°C, and set aside;

[0032] (2) Add 760 mL of water to the frozen fish bone paste to thaw, then stir for 5 minutes, add 2.5 grams of compound protease (mixed with flavor protease and papain at a mass ratio of 1:1), and carry out at 60°C and pH 7.0. Enzymolysis reaction was carried out for 20 minutes, and then incubated at 95°C for 3 minutes to inactivate the enzyme. After cooling to room temperature, centrifuge at 6000g for 4 minutes to remove fat and obtain supernatant and precipitate.

[0033] (3) The supernatant obtained in step (2) was ultrafiltered twice through a f...

Embodiment 2

[0047] The preparation of embodiment 2 fishbone small molecule polypeptide chelated calcium powder

[0048] (1) Take 2,000 grams of flounder bones, thaw, remove the residual fish meat on the surface, wash, cook the fish bones at 120°C for 15 minutes, beat the fish bones at 12,000 rpm, cool, and drain to obtain 780 grams. Gram fish bone paste, frozen to -10°C, set aside;

[0049] (2) Add 1250 mL of water to the frozen fish bone paste to thaw, then stir for 5 minutes, add 4.5 grams of compound protease (flavor protease and papain are mixed at a mass ratio of 1:1), and carry out at 60°C and pH 7.0. Enzymolysis reaction was carried out for 30 minutes, then incubated at 95°C for 3 minutes to inactivate the enzyme, cooled to room temperature and centrifuged at 6000g for 5 minutes to remove fat and obtain supernatant and precipitate.

[0050] (3) The supernatant obtained in step (2) is ultrafiltered twice through a filter membrane with a molecular weight of 3 ku to obtain 800 ml of ...

Embodiment 3

[0054] The preparation of embodiment 3 fishbone small molecule polypeptide chelated calcium powder

[0055] (1) Take 1500 grams of flounder bones, thaw, remove the remaining fish meat on the surface, wash, cook the fish bones at a pressure of 0.160Mpa and 115°C for 20min, beat with a tissue masher at 12000rpm, cool and drain , to obtain 580 grams of fish bone paste, frozen to -10 ℃;

[0056] (2) Add 1050 mL of water to the frozen fish bone paste to thaw, then stir for 4 minutes, and add 3.3 grams of compound protease (mixture of flavor protease and papain at a mass ratio of 1:1). Then carry out enzymatic hydrolysis reaction at 55°C and pH 7.2 for 25 minutes, then incubate at 95°C for 3 minutes to inactivate the enzyme, cool to room temperature and centrifuge at 6000g for 5 minutes to remove fat and obtain supernatant and precipitate.

[0057] (3) The supernatant obtained in step (2) was ultrafiltered twice through a filter membrane with a molecular weight of 3 ku to obtain 65...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com