Manufacturing method and device of channel double-diffusion metal oxide semiconductor

A technology for oxidizing semiconductors and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] By adding a heat treatment step in the process of the backside of the wafer, the probability of soft breakdown failure of the trench (trench) double diffused metal oxide semiconductor (Double Metal Oxide Semiconductor DMOS) is reduced or does not occur through heat treatment, and then Obtain high quality wafer products.

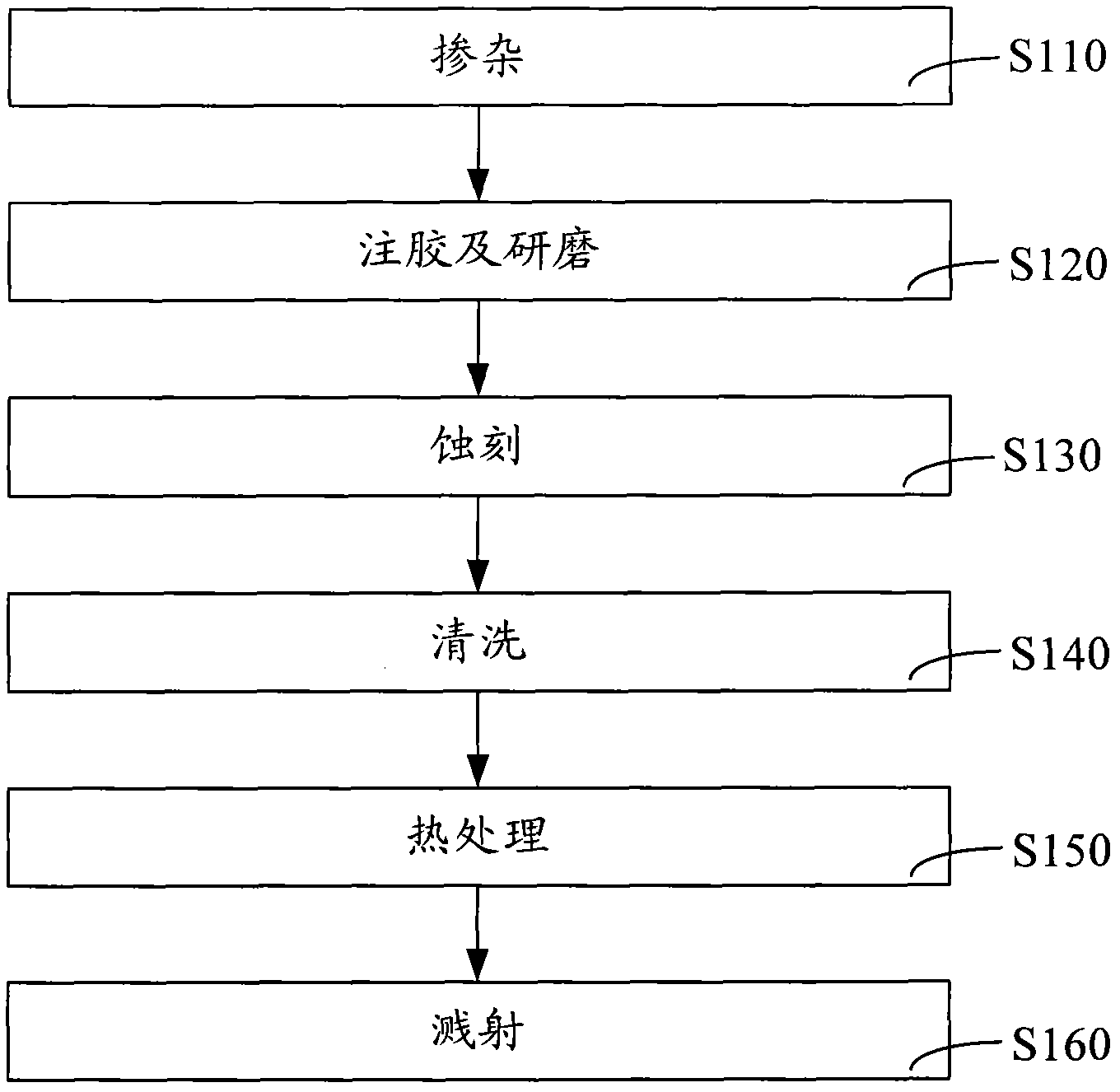

[0028] like Figure 1-7 As shown, a trench double-diffused metal oxide semiconductor manufacturing method includes the following steps:

[0029] First, step S110, doping the back of the wafer, controlling a certain energy to implant atoms or ions into the back of the wafer, so as to form a surface layer with special properties in the selected area to achieve the purpose of doping.

[0030] Step S120 , sticking a protective tape on the front side of the wafer, the thickness of the protective tape is greater than or equal to the difference between the minimum grinding thickness limit of the grinding device and the predetermined wafer thickness. The bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com