A mid-pressure hydrocracking method for producing jet fuel

A hydrocracking and jet fuel technology, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problem of unqualified smoke point of kerosene products, and achieve low operating cost, low equipment investment and low BMCI value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

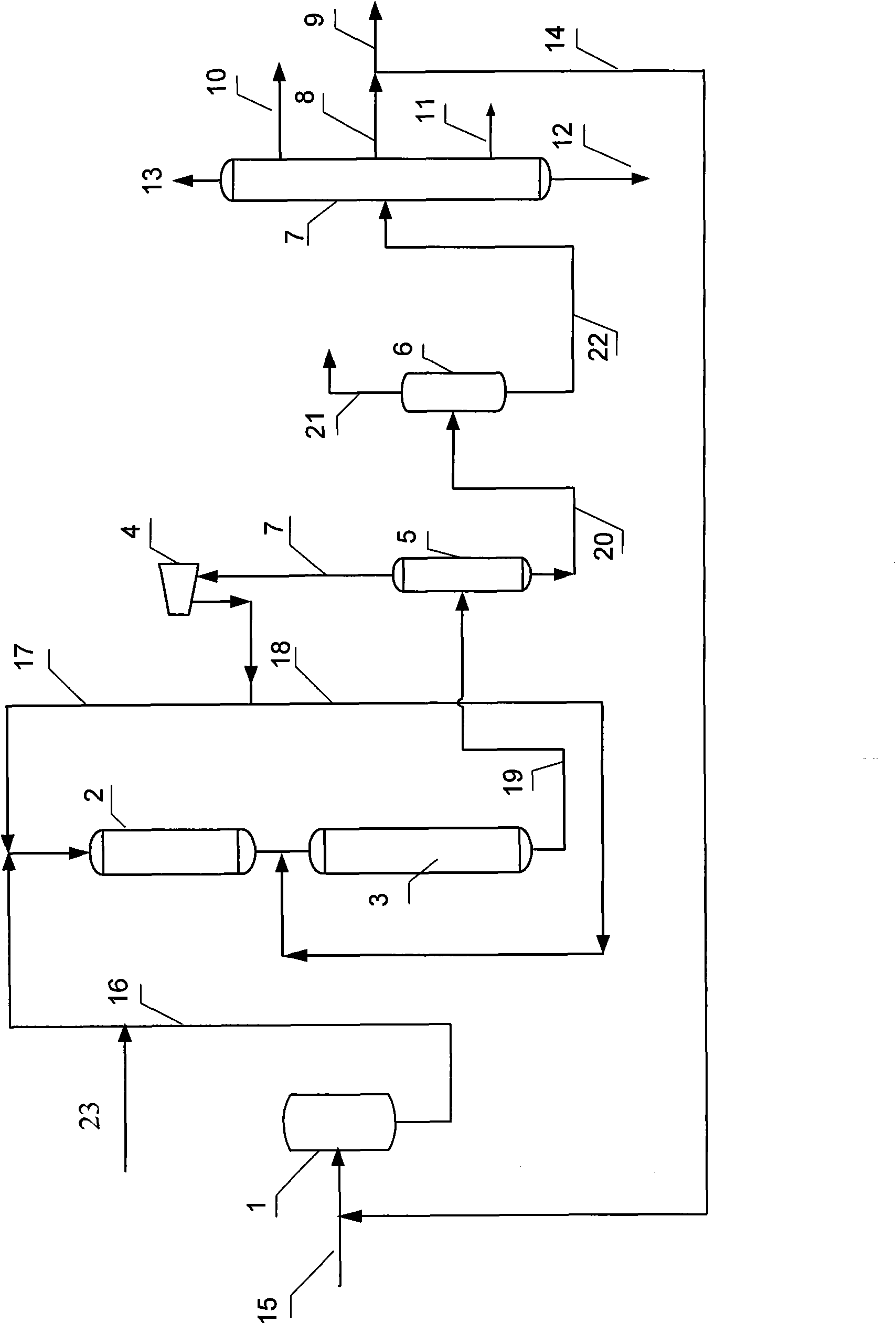

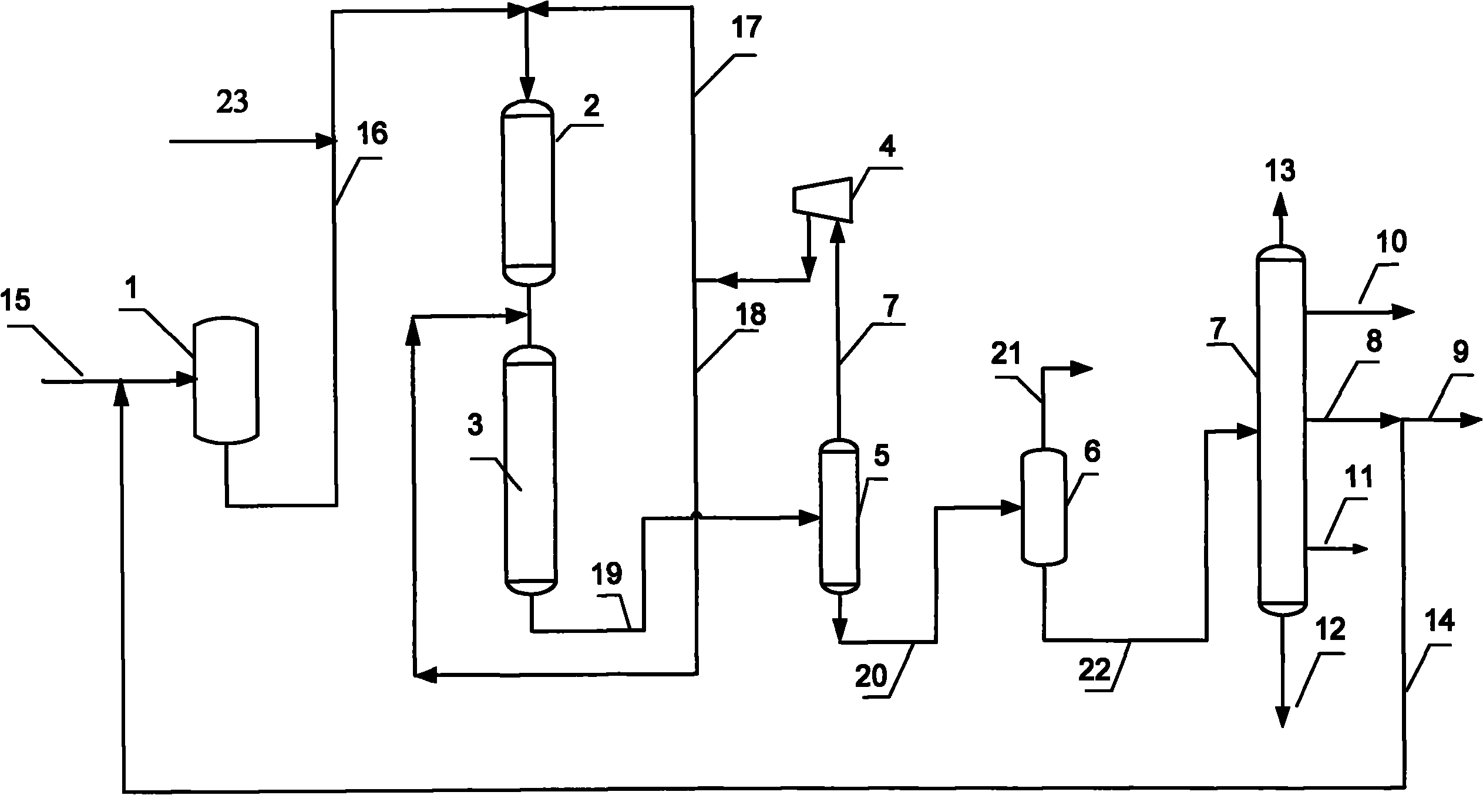

Method used

Image

Examples

Embodiment 1

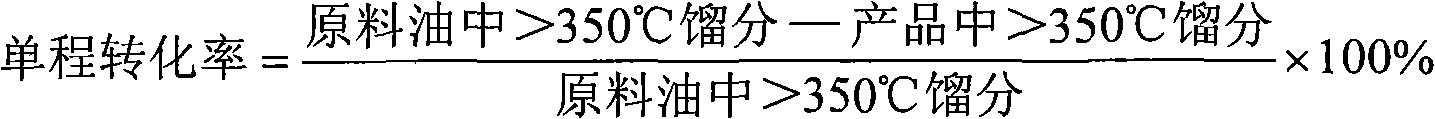

[0033] Using raw material A, the reaction pressure is 10.5MPa, the refining section is 373°C, and the refining / cracking volume space velocity is 1.2h respectively -1 、2.0h -1 , under the reaction conditions that the volume ratio of hydrogen to oil is 1200, using the method provided by the invention, a hydrocracking test of 30% kerosene fraction circulation is carried out, and the single-pass conversion rate of the >350 ° C fraction is controlled to be about 65%. The test results are shown in Table 2 and shown in Table 3. Table 2 lists the distribution data based on liquid products, and Table 3 lists the distribution data based on raw oil. As can be seen from Table 2, by the method provided by the invention, the yield of kerosene fraction is 13% by weight, and the smoke point is 25.0mm, which can satisfy the index of No. 3 jet fuel (No. 3 jet fuel smoke point is not less than 25.0mm), The yield of light naphtha is 4.92% by weight, the yield of tail oil is 37.20% by weight, an...

Embodiment 2

[0039] Using raw material A, the reaction pressure is 10.5MPa, the refining section is 373°C, and the refining / cracking volume space velocity is 1.2h -1 / 2.0h -1 , under the reaction conditions that the volume ratio of hydrogen to oil is 1200. Using the method provided by the present invention, a hydrocracking test of 50% kerosene fraction circulation was carried out, and the single-pass conversion rate of the >350°C fraction was controlled to be about 65%. The test results are shown in Table 6. As can be seen from Table 6, through the method provided by the present invention, the yield of kerosene fraction is 9.47% by weight, and the smoke point is 26.0mm, which can meet the index of 3 jet fuel. The yield of light naphtha is 5.10% by weight, the yield of tail oil is 37.2% by weight, and the BMCI values are 5.2 and 11.9 respectively, all of which are high-quality steam cracking raw materials for ethylene production.

[0040] Table 1

[0041] Raw oil number

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Smoke point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com