Preparation method of medicinal calcium folinate

A technology of calcium folinate and folic acid, which is applied in the field of preparation of calcium folinate for medicine, can solve the problems of high temperature and pH value, the need to improve the yield and purity, and the low yield of calcium folinate, so as to improve the yield, The effect of reducing impurities and improving yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

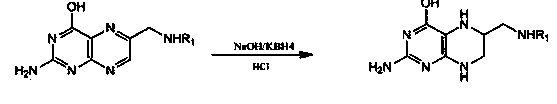

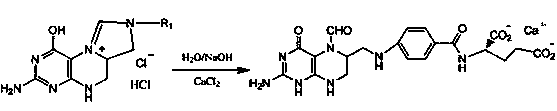

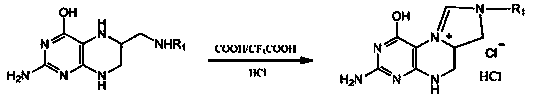

Method used

Image

Examples

Embodiment 1

[0025] Put 10kg of water in the metering tank, put it into the hydrogenation kettle after metering, stir, add 1kg of folic acid, stir well, add catalyst zinc citrate 0.01kg, potassium borohydride 1kg, after adding potassium borohydride, the temperature is controlled at 45 ~50°C, stirring and reacting for 2-3 hours, adding 0.3 kg of disodium ethylenediaminetetraacetic acid, adjusting the pH of the feed solution to 4.2-4.5 with hydrochloric acid, and centrifuging to obtain tetrahydrofolate.

[0026] Put the obtained tetrahydrofolate into the acylation kettle, then add 7kg of formic acid and 1.5kg of trifluoroacetic acid, stir, react at a temperature of 60-70°C for 2 hours, recover formic acid by distillation, and centrifuge to obtain formyltetrahydrofolate hydrochloride .

[0027] Put the obtained formyl tetrahydrofolate hydrochloride into a hydrolysis kettle, then add 16kg of water, and hydrolyze at a temperature of 70-75°C and a pH of 7.5-8.0 for 2 hours. Add an appropriate a...

Embodiment 2

[0029] Put 10kg of water in the metering tank, put it into the hydrogenation kettle after metering, stir, add 1kg of folic acid, stir well, add catalyst zinc citrate 0.01kg, potassium borohydride 1kg, after adding potassium borohydride, the temperature is controlled at 45 ~50°C, stirring and reacting for 2-3 hours, adding 0.3 kg of disodium edetate, adjusting the pH of the feed solution to 4.2-4.5 with hydrochloric acid, and centrifuging to obtain tetrahydrofolate.

[0030] Put the obtained tetrahydrofolate into an acylation kettle, then add 6kg of formic acid and 1.1kg of trifluoroacetic acid, stir, react at a temperature of 55-60°C for 1.5 hours, recover formic acid by distillation, and centrifuge to obtain formyltetrahydrofolate hydrochloride .

[0031] Put the obtained formyl tetrahydrofolate hydrochloride into a hydrolysis kettle, then add 14kg of water, hydrolyze at a temperature of 65-70°C and a pH of 7.2-7.5 for 1.5 hours; add an appropriate amount of activated carbon ...

Embodiment 3

[0033] Put 8kg of water in the metering tank, put it into the hydrogenation kettle after metering, stir, add 1kg of folic acid, stir well, add catalyst zinc stearate 0.005kg, potassium borohydride 0.8kg, after adding potassium borohydride, the temperature is controlled at 40-45°C, stirring and reacting for 1-2 hours, adding 0.25-0.3 kg of organic amine carboxylate, adjusting the pH of the feed solution to 3-4 with hydrochloric acid, and centrifuging to obtain tetrahydrofolate;

[0034] Put the obtained tetrahydrofolate into the acylation kettle, then add 7kg of formic acid and 1.5kg of trifluoroacetic acid, stir, react at a temperature of 60-70°C for 2 hours, recover formic acid by distillation, and centrifuge to obtain formyltetrahydrofolate hydrochloride .

[0035] Put the obtained formyl tetrahydrofolate hydrochloride into a hydrolysis kettle, then add 19kg of water, and hydrolyze for 2.5 hours at a temperature of 75-80°C and a pH of 8.3-8.5; add an appropriate amount of ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com