Method and device for treating high-salt content water by hydro-power molecular membrane

A technology of molecular membrane and high salt water, which is applied in the direction of heating water/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the constraints of large-scale engineering application of membrane distillation, no high-quality products have been launched, and membrane wetting cannot be solved and other problems, to achieve the effect of excellent and stable effluent water quality, good effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

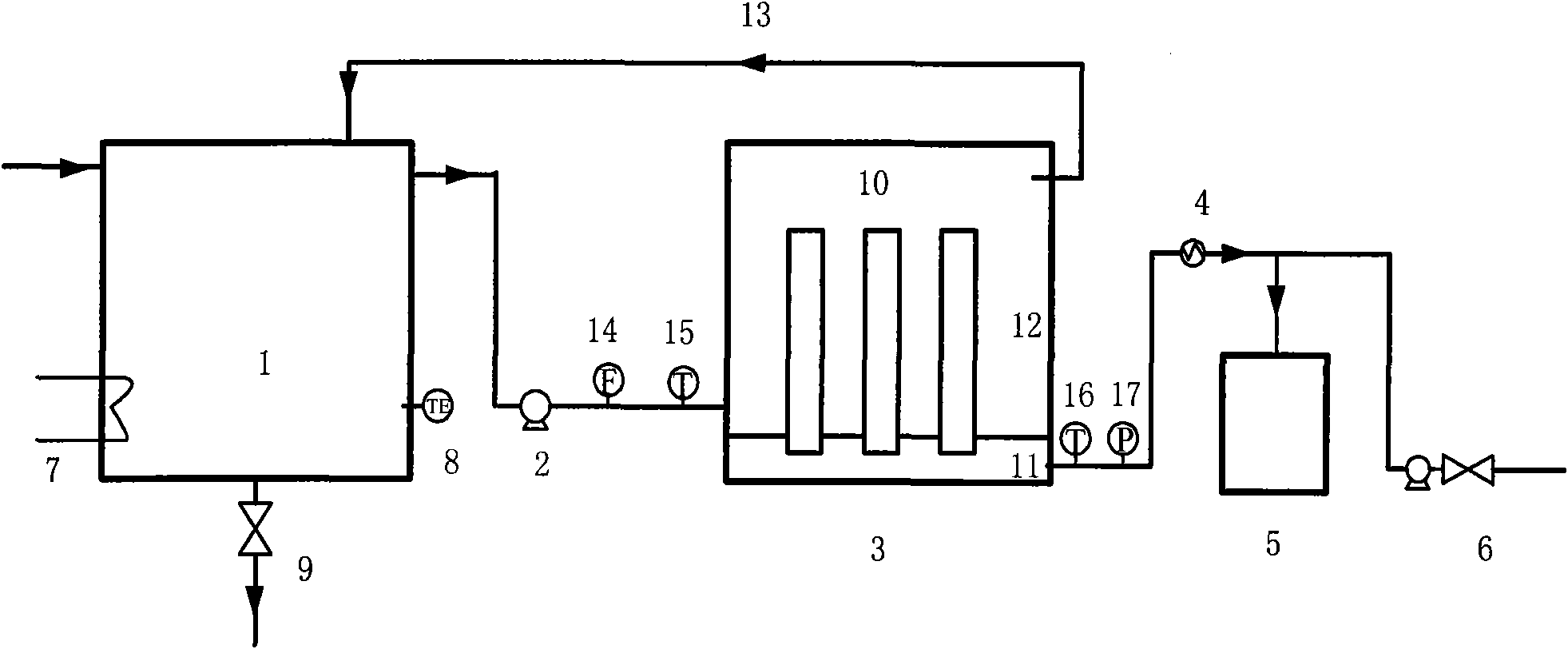

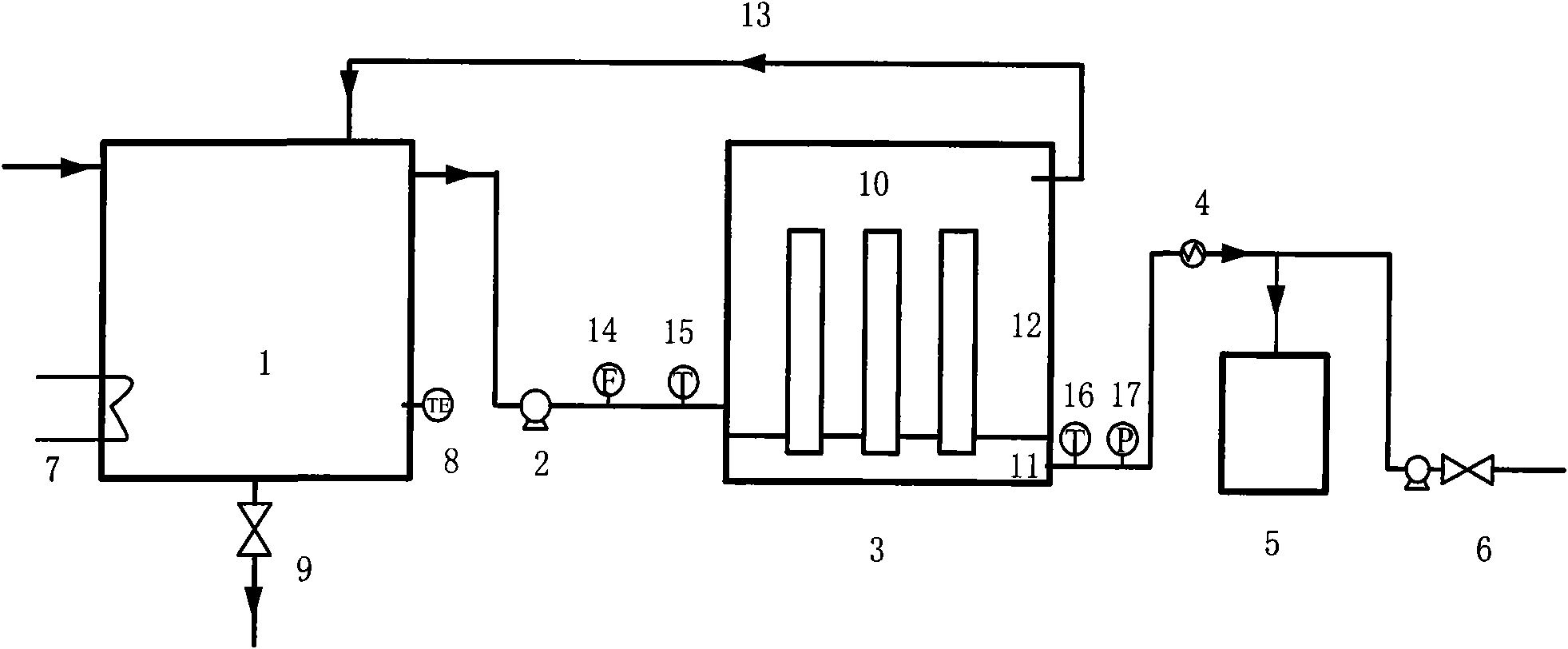

Image

Examples

example 1

[0029] Example 1: The concentrated brine produced by the RO system from the sewage source, the water quality conditions are: conductivity 100000μs / cm, chromaticity 80. The device for treating high brine with hydroelectric molecular membrane is used to treat wastewater. The membrane group adopts a tubular hydroelectric molecular membrane membrane, the temperature of the feed liquid is 40°C, and the vacuum degree is -0.1MPa. The final effluent conductivity is 53μs / cm, no color, the desalination rate reaches 99.9%, the chroma removal rate is 100%, and the average flux of membrane produced water has been maintained at 10L / m 2 .h;

example 2

[0030] Example 2: The source of sewage is the effluent of the biochemical system of a coking plant, and the water quality condition is: COD Cr The content is 680mg / L, the SS is 600mg / L, the conductivity is 8900μs / cm, and the chromaticity is 500; the device for treating high salt water with hydroelectric molecular membrane is used to treat the wastewater. The inlet water temperature is 80°C and the vacuum degree is -0.1MPa. Final effluent conductivity is 90μs / cm, COD Cr 50mg / L, no color, the total nitrogen concentration is less than 10mg / L, that is, the desalination rate is 99%, 100% removes chroma, and reaches the industry’s first-class discharge standard A. The average flux of membrane-produced water has been maintained at 100L / m 2 .h.

example 3

[0031]Example 3: The source of sewage is seawater, and the water quality conditions are: conductivity 32000μs / cm, chromaticity 30. The device for treating high brine with hydroelectric molecular membrane is used to treat wastewater. The membrane group adopts 14 pipe-type hydroelectric molecular membrane membranes. The feed water temperature is 60°C and the vacuum degree is -0.1MPa. The final conductivity of the effluent is 3.0μs / cm, no color, the desalination rate reaches 99.99%, 100% removes the color, and the average flux of the membrane produced water has been maintained at 25L / m 2 .h;

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com