Mineral dressing method for separating Cu-Pb-Zn-Fe multi-metal sulfide mineral

A beneficiation method and multi-metal technology, applied in solid separation, flotation, etc., can solve the problems of poor product quality, mutual inclusion, low metal recovery rate, etc., to improve recovery rate, reduce pyrite content, and good selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

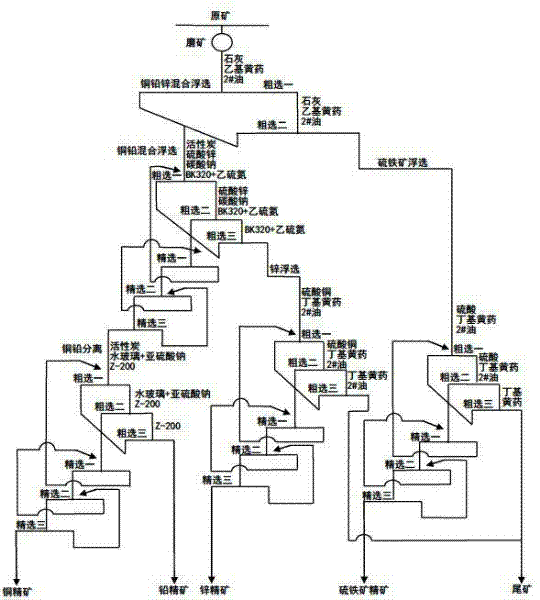

Image

Examples

Embodiment 1

[0018] Grind 1 ton of raw ore until the fineness is -74μm and the content is 70%, add 12kg of lime, and add 100g of ethyl xanthate after 5 minutes to carry out mixed flotation of copper, lead and zinc, which is divided into two roughing; Add 200g of activated carbon to the mixed concentrate after selection, add 1000g of zinc sulfate and 500g of sodium carbonate after 5 minutes, add 100g of BK320 and 100g of ethyl disulfide after 3 minutes for mixed flotation of copper and lead, including three times of roughing and three times of beneficiation Add 150g of activated carbon to the mixed concentrate after copper-lead flotation to remove the drug, add 300g of water glass and 300g of sodium sulfite to suppress lead minerals after 5 minutes, add 150g of Z-200 after 3 minutes, and pass three times of roughing and three times of refining Copper concentrate and lead concentrate are obtained by selection; 8kg sulfuric acid is added to the tailings after copper-lead-zinc mixed flotation t...

Embodiment 2

[0020] Grind 1 ton of raw ore until the fineness is -74μm and the content is 85%, add 4kg of lime, and add 150g of ethyl xanthate after 5 minutes to carry out mixed flotation of copper, lead and zinc, which is divided into two roughing; First add 80g of activated carbon to the mixed concentrate after selection, add 600g of zinc sulfate and 300g of sodium carbonate after 5 minutes, add 60g of BK320 and 60g of ethylsulfite after 3 minutes for mixed flotation of copper and lead, including three times of roughing and three times of beneficiation Add 50g of activated carbon to the mixed concentrate after copper-lead flotation to remove the drug, add 200g of water glass and 200g of sodium sulfite to suppress lead minerals after 5 minutes, add 100g of Z-200 after 3 minutes, and pass three times of roughing and three times of refining Copper concentrate and lead concentrate are obtained by selection; 7kg of sulfuric acid is added to the tailings after copper-lead-zinc mixed flotation t...

Embodiment 3

[0022] After grinding 1 ton of raw ore to a fineness of -74μm and a content of 90%, add 8kg of lime and 5 minutes later add 200g of ethyl xanthate to carry out mixed flotation of copper, lead and zinc, which is divided into two roughings; First add 100g of activated carbon to the mixed concentrate after selection, add 1200g of zinc sulfate and 600g of sodium carbonate after 5 minutes, add 120g of BK320 and 120g of ethyl disulfide after 3 minutes for mixed flotation of copper and lead, including three times of roughing and three times of beneficiation Add 100g of active carbon to the mixed concentrate after copper-lead flotation to remove the drug, add 400g of water glass and 400g of sodium sulfite to suppress lead minerals after 5 minutes, add 80g of Z-200 after 3 minutes, and pass three times of roughing and three times of refining Copper concentrate and lead concentrate are obtained by selection; 4kg of sulfuric acid is added to the tailings of copper-lead-zinc mixed flotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com