Blast furnace coal gas overlong pulse bag type dust collector

A bag-type dust collector and blast furnace gas technology, used in dust collectors, chemical instruments and methods, dispersed particle filtration, etc., can solve the processing and transportation difficulties of dust removal equipment, the increase in the area of the dust removal system, and the unstable processing quality. problems, to achieve the effect of shortening the processing cycle of the equipment, good economic benefits, and optimizing the structure and size of the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

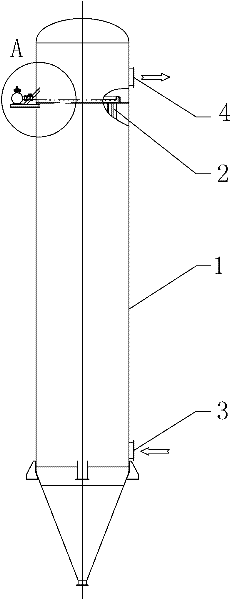

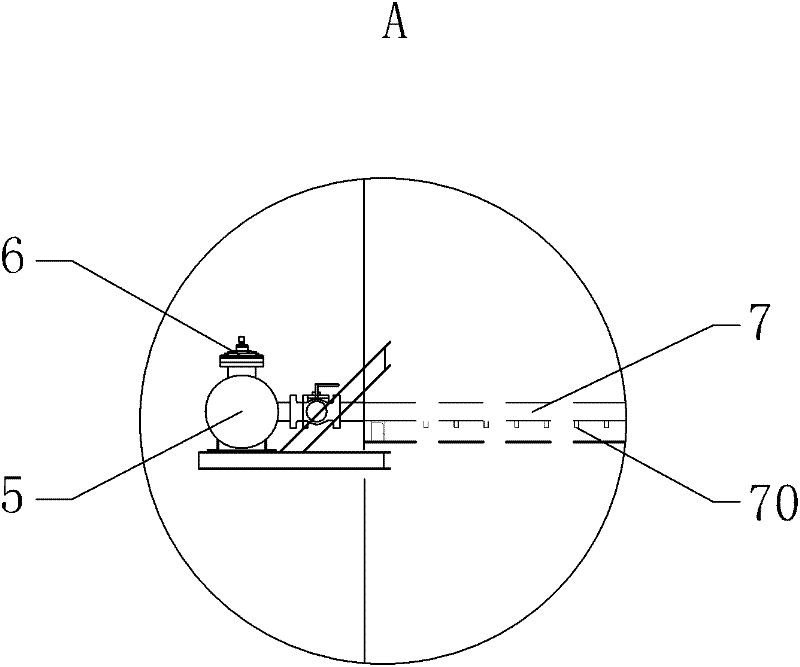

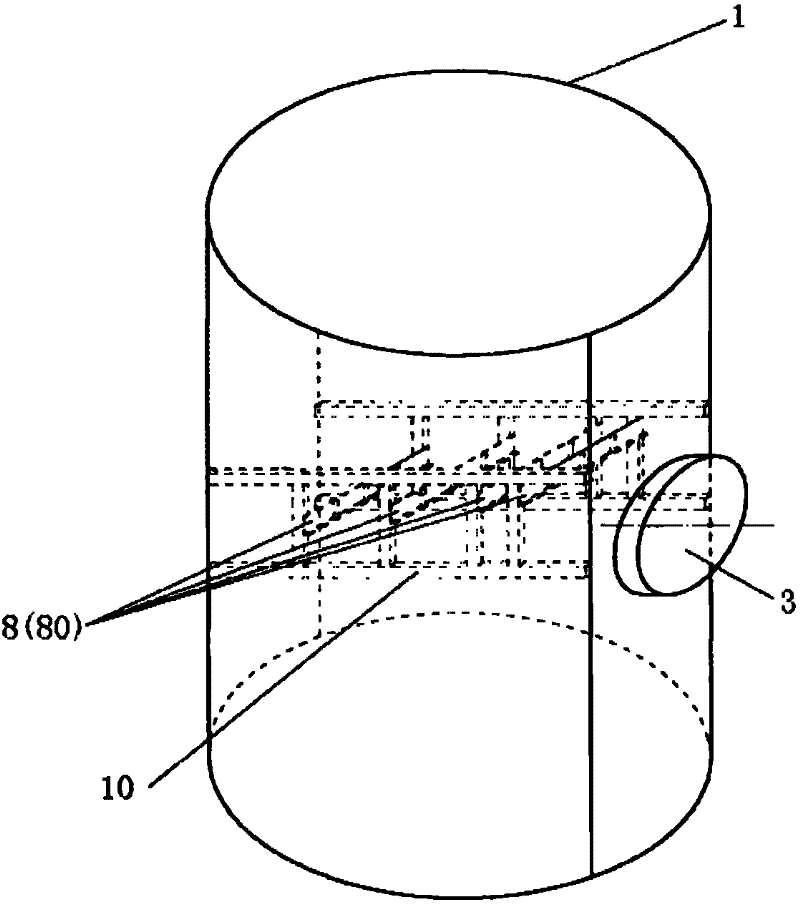

[0025] like figure 1 The shown ultra-long pulse bag-type dust collector for blast furnace gas includes a dust collector cylinder 1, a filter bag 2, an injection device and an air intake and diversion combined device. Wherein: an air inlet 3 and an air outlet 4 are opened on the side wall of the cylinder body 1 , and the filter bag 2 is arranged in the cylinder body 1 above the air inlet 3 and below the air outlet 4 . The selection of various components in the dust collector is as follows:

[0026] Cylinder 1: Its diameter is between 2600-5000mm.

[0027] Filter bag 2: The length is 12~16m, and the diameter is 130~180mm. The filter material of filter bag 2 can be the traditional filter material, such as glass fiber needle felt, glass fiber P84 composite needle felt (Flumet ) or glass fiber coated filter material, etc.; metal filter material, such as metal sintered wire mesh or metal fiber felt or sintered metal powder, etc.; ceramic filter material, such as ceramic fib...

Embodiment 2

[0036] This embodiment is basically the same as the first embodiment, the difference is that this embodiment adopts the following Figure 5 The shown air inlet guide is mainly a ash guide plate 11, the ash guide plate 11 is arranged in the cylinder 1 on the upper part of the air inlet 3, and the bottom of the ash guide plate 11 is composed of a grid plate 110, so that from When the dust-laden airflow entered by the air inlet 3 passes through the grid plate 110 , some large-sized dust particles that cannot pass through the grid plate can be filtered.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com