Plasma deposition

一种等离子体、氮等离子体的技术,应用在等离子体、晶体生长、来自化学反应性气体等方向,能够解决影响薄膜性质等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

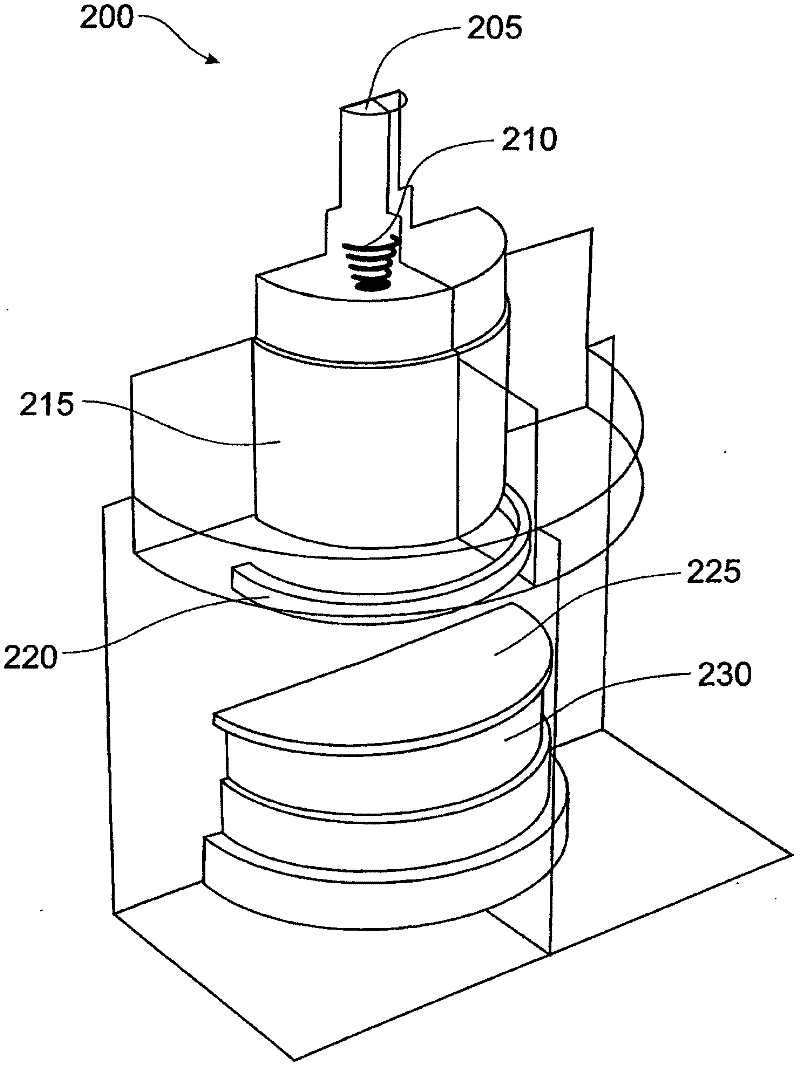

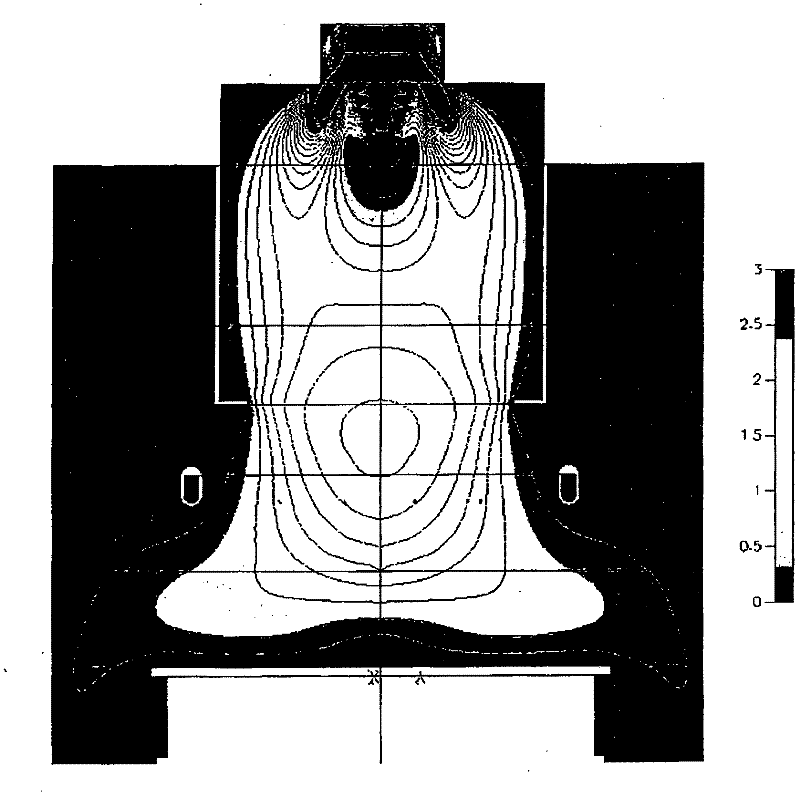

[0048] The present inventors have identified a specific apparatus for producing Group III metal nitride thin films that substantially reduces substrate and / or thin film damage due to collisions of unwanted high energy reactive nitrogen species, At the same time, it advantageously promotes the uniform growth of high-quality Group III metal nitride films.

[0049] The inventors have further determined the importance of varying one or more distances within the reaction chamber and introducing a purge gas and / or a surfactant into the reaction environment in the production of high quality thin films in an industrially efficient process. value.

[0050] figure 1 A schematic diagram of one embodiment of an apparatus 100 for depositing Group III metal nitride thin films on a substrate is shown. figure 1They are shown only for the purpose of representing the general layout of the various components required. Apparatus 100 includes a reaction chamber 105 containing a substrate holder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com