Transportation of object of micro-size and retrieval of mechanical work by means of constant electric field

A mechanical work, micron-level technology, applied in micro manipulators, manipulators, electrostatic motors, etc., can solve problems such as inability to move in two dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

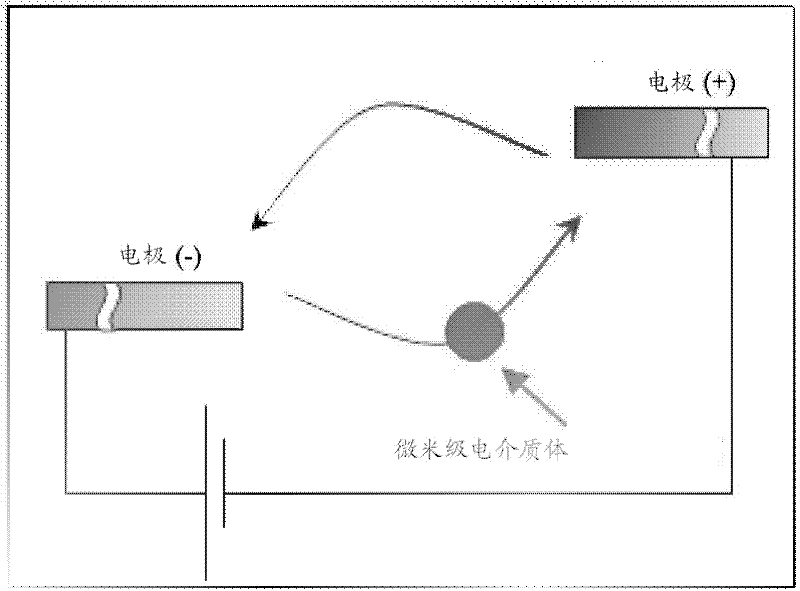

[0263] In this example, using an anode and a cathode, oil used as an insulating fluid, and water droplets used as a dielectric body, it was demonstrated whether rotational motion occurs. The materials and methods are as follows:

[0264] (Materials and Methods)

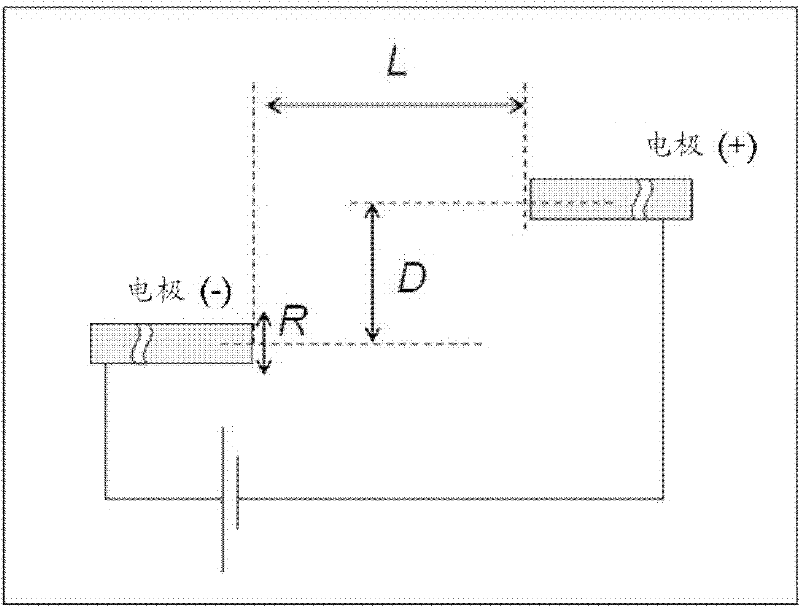

[0265] (about figure 2 )

[0266] Anode: made of tungsten (manufactured by NPS co., LTD.)

[0267] Cathode: made of tungsten (manufactured by NPS co., LTD.)

[0268] Oil: Mineral oil (produced by Nacalai Tesque)

[0269] Water droplet: prepared from phospholipid DOPC (manufactured by Wako Pure Chemical Industries, Ltd.)

[0270] Electrode Arrangement: The anode and cathode were arranged 50 microns apart from each other in the direction parallel to the central axis and in the direction perpendicular to the central axis.

[0271] The way of applying voltage: 100V constant voltage

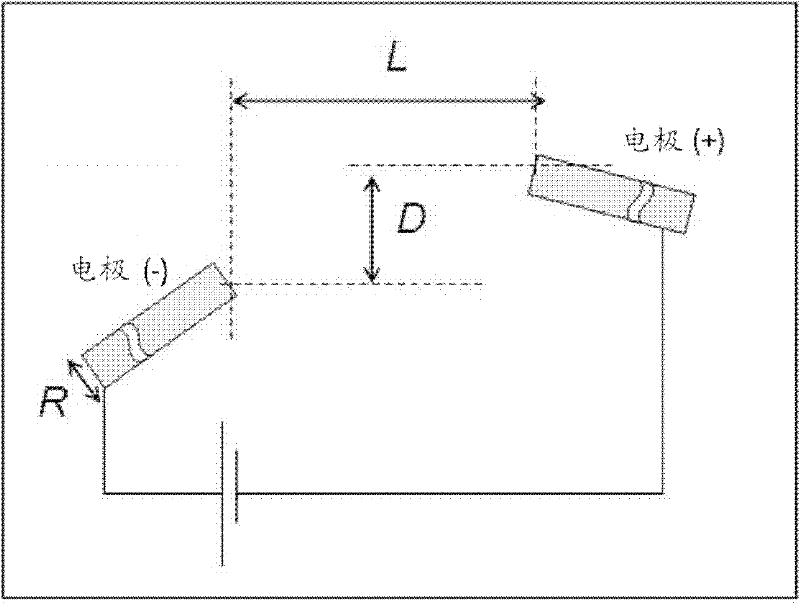

[0272] (about image 3 )

[0273] Anode: made of tungsten carbide (manufactured by NPS co., LTD.)

[0274] Cathode: made of tungs...

example 2

[0310] (Example 2: Material of Dielectric Body)

[0311] In this example, it was shown that various conditions were tested and the results revealed the following features. Basic experimental techniques were performed according to Example 1.

[0312] (material of dielectric body)

[0313] In this example, it was confirmed that the dielectric body may be of any material, and it was confirmed that, in addition to minute water droplets, movable polyethylene beads, glass beads, etc. also perform similar motions.

example 3

[0314] (Example 3: Electrode material)

[0315] In this example, it was shown that various conditions were tested and the results revealed the following characteristics. Basic experimental techniques were performed according to Example 1.

[0316] In this example, confirm that the material of the electrodes is not relevant (only conductivity is required). That is, confirmed by tungsten, tungsten carbide and gold. image 3 is an instance of tungsten, Figure 4 is an example of tungsten carbide, gold has also been confirmed to have a similar effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com