Aluminium alloy armored parallel assignment intelligent composite power cable and manufacture method thereof

A technology of parallel arrangement of power cables, which is applied in the field of intelligent composite power cables and its manufacturing, can solve the problems of consuming manpower and material resources, reduce electric field strength, reduce electromagnetic radiation and electrochemical corrosion, and simplify the manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

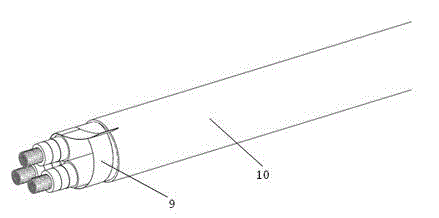

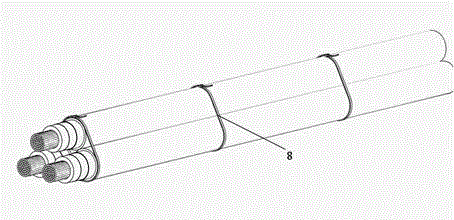

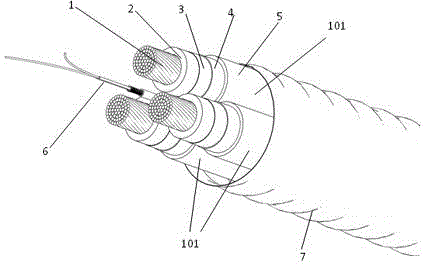

[0024] The following combination Figure 3 to Figure 5 , a preferred embodiment of the present invention is described in detail.

[0025] like image 3 and Figure 4 As shown, the aluminum alloy armored parallel arrangement intelligent composite power cable according to the present invention includes: three power cables 101 arranged in parallel with each other in a triangular cross-section, and the outermost insulating surfaces between the two are in tangential contact; The heat-sensitive optical fiber cable 6 arranged in the geometric space center 16 formed by the arrangement of the three power cables 101 and arranged parallel to the power cables 101; Tube 7.

[0026] Wherein, the aluminum alloy armored sheath pipe 7 is a corrugated pipe made by a corrugated molding die, without any plastic sheath layer on the outside.

[0027] The single power cable 101 includes: a conductor 1 formed by twisting multi-core pure aluminum wires, which is suitable for the transmission of AC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com