Method for indirectly measuring silicon content in defoaming agent through flame atomic absorption

A flame atomic absorption and silicon content technology, which is used in the preparation of test samples and the measurement of color/spectral properties. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Accurately weigh 0.5g of defoamer sample (T-20XP silicone food defoamer, produced by Tengda Auxiliary Factory in Funing County, Jiangsu Province) into a microwave digestion tube, add 10mL of concentrated nitric acid with a concentration of 69% by mass, and microwave After digestion, a clear digest solution was obtained.

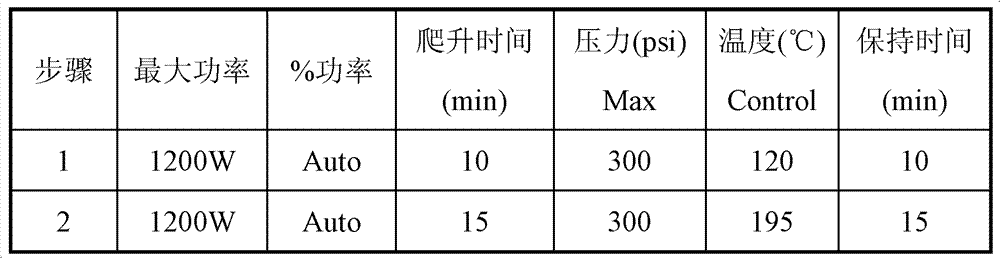

[0036] The heating program of microwave digestion is as follows:

[0037]

[0038] Among them, the maximum power should be adjusted appropriately depending on the specific amount of the digested sample. The best condition is to use pressure control or temperature control. Time control is not applicable. The optimal condition is temperature control. The digestion temperature and digestion time are suitable for complete digestion. , the optimal conditions are shown in the table above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com