Production method of solar energy level polysilicon ingot with crystalline grains arranged regularly

A technology of solar energy level and production method, which is applied in the field of crystalline silicon manufacturing, can solve problems affecting the photoelectric conversion efficiency and life of crystalline silicon solar cells, affecting the performance of photovoltaic devices, and reducing the diffusion length of minority carriers, so as to reduce the probability of cracking and increase Productivity and the effect of improving the lifespan of the few births

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

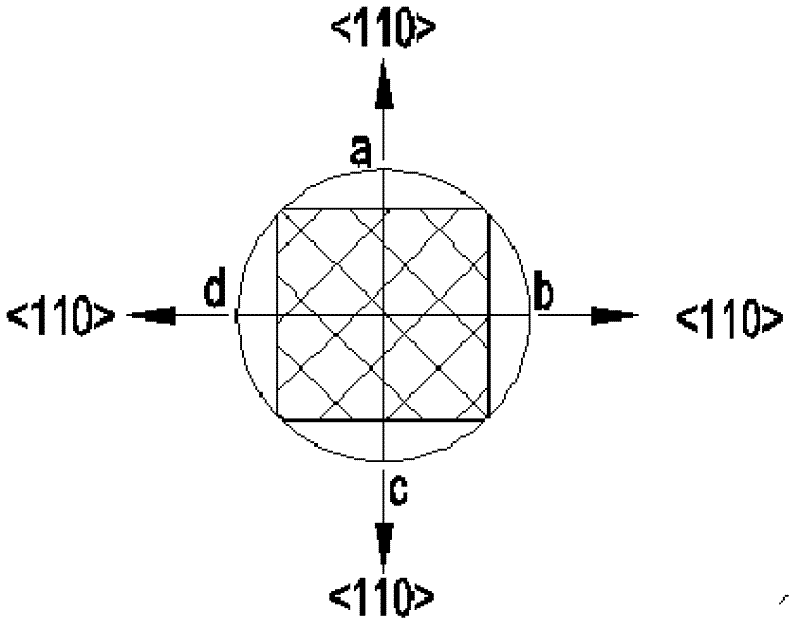

[0027] A 500 kg ingot is produced in a silicon ingot furnace, and a square flat-bottomed quartz crucible is used as a container for crystal growth. The accommodation size of the quartz crucible is 840mm (length) × 840mm (width) × 480mm (height). Place a seed layer on the bottom plane of the crucible, such as figure 2 As shown, the seed layer is composed of 49 115mm (length) × 115mm (width) × 30mm (height) seed crystals closely arranged, and any two adjacent seed crystals are respectively "+-type seed crystals" ( figure 2 "+" mark in the center) and "×-type seed crystal" ( figure 2Mark "×" in the center), the angle between the crystal directions of two adjacent seed crystals along the normal direction of the splicing surface (ie the contact surface) (also known as the crystal direction angle) is 45±3°, all the seeds The crystal orientation along the normal direction of the bottom plane of the crucible (ie, the crystal orientation along the vertical direction of the crucibl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Life expectancy | aaaaa | aaaaa |

| Life expectancy | aaaaa | aaaaa |

| Crack depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com