Etchant of molybdenum and/ or aluminum containing metal film for OLED (Organic Light Emitting Diode) and preparation method thereof

An etching solution, aluminum metal technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of difficulty in controlling the taper angle of molybdenum metal film at 20°-70°, easy to generate residues, affecting etching accuracy, etc. problems, to achieve the effect of improving the solid-liquid interfacial tension, improving the etching accuracy and stabilizing the etching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

[0030] 50 parts by weight of phosphoric acid aqueous solution with a mass percent concentration of 52%, 1 part by weight of an aqueous solution of nitric acid with a mass percent concentration of 65%, 1 part by weight of betaine amphoteric surfactant lauramide propyl hydroxysultaine and deionized After mixing 48 parts by weight of water, the etching solution provided by the present invention was obtained.

[0031] Following exactly the same steps as above, only the above raw materials were replaced as shown in Table 1 to obtain the etching solutions provided in Examples 2-11 and Comparative Examples 1-7.

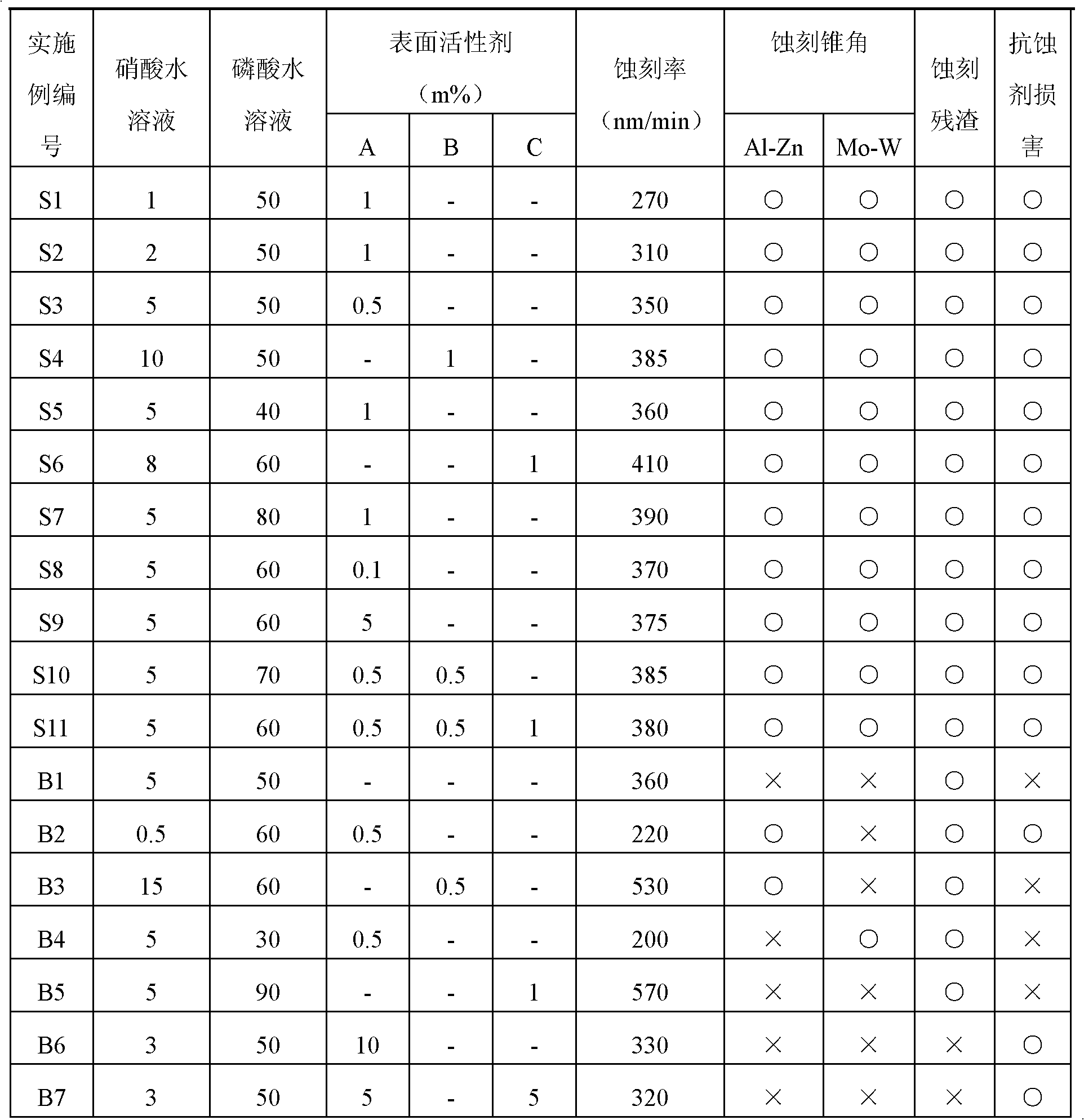

[0032] Table 1. Etching solution composition and etching effect list

[0033]

[0034] Surfactant A - lauryl amidopropyl hydroxysultaine

[0035] Surfactant B - lauryl amidopropyl betaine

[0036] Surfactant C - Cocamidopropyl Hydroxysultaine

[0037] Etching angle ○——cone angle is 20°-70°

[0038] Etching angle ×—cone angle is less than 20° or greater than 70°

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com