On-line rust-proof method for twisted steel

A technology of threaded steel bar and water vapor, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problem of easy rust on the surface of threaded steel bar, and achieve continuous production, good surface gloss, and increased production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Taking the threaded steel bar with a diameter of 32mm after waste heat treatment as an example, the rolled steel bar enters the step-by-step cooling bed at a speed of 7.2m / s. The temperature of the upper cooling bed is 620°C. Spray while walking, the spray time is 2 minutes, then cool naturally. The treated steel bar was sampled and compared with the untreated steel bar for anti-corrosion performance. The sample was placed in the open air and sprayed with rainwater twice a day. The untreated steel bar began to rust within 1 day, and the treated steel bar began to rust after 9 days. point, the anti-corrosion ability is obviously improved.

Embodiment 2

[0026] Taking the threaded steel bar with a diameter of 28mm after waste heat treatment as an example, the rolled steel bar enters the step-by-step cooling bed at a speed of 9.3m / s. The temperature of the upper cooling bed is 580°C. Spray while walking, and the spray time is 3.5 minutes, after which it cools down naturally. The treated steel bar was sampled and compared with the untreated steel bar for anti-corrosion performance. The sample was placed in the open air and sprayed with rainwater twice a day. The untreated steel bar began to rust within 1 day, and the treated steel bar began to rust after 10 days. point, the anti-corrosion ability is obviously improved.

Embodiment 3

[0028] Taking the threaded steel bar with a diameter of 40mm after waste heat treatment as an example, the rolled steel bar enters the step-by-step cooling bed at a speed of 3.5m / s. The temperature of the upper cooling bed is 650°C. Spray while walking, and the spray time is 3 minutes, after which it cools down naturally. The treated steel bar was sampled and compared with the untreated steel bar for anti-corrosion performance. The sample was placed in the open air and sprayed with rainwater twice a day. The untreated steel bar began to rust within 1 day, and the treated steel bar began to rust after 7 days. point, the anti-corrosion ability is obviously improved.

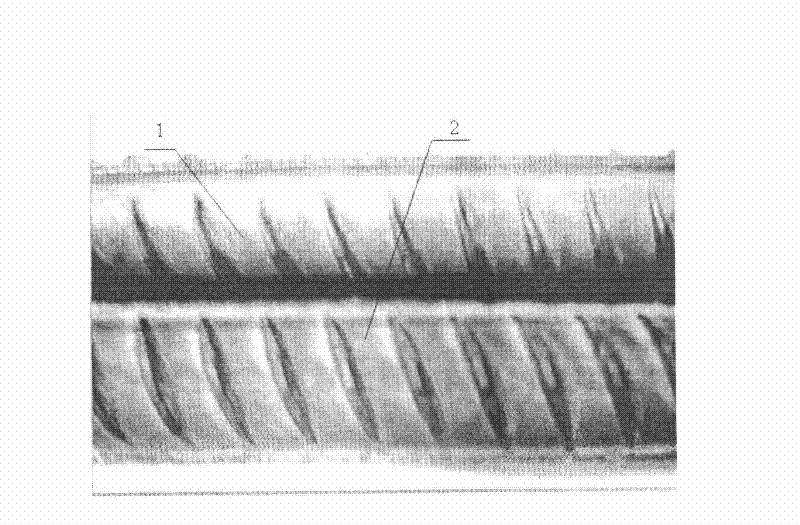

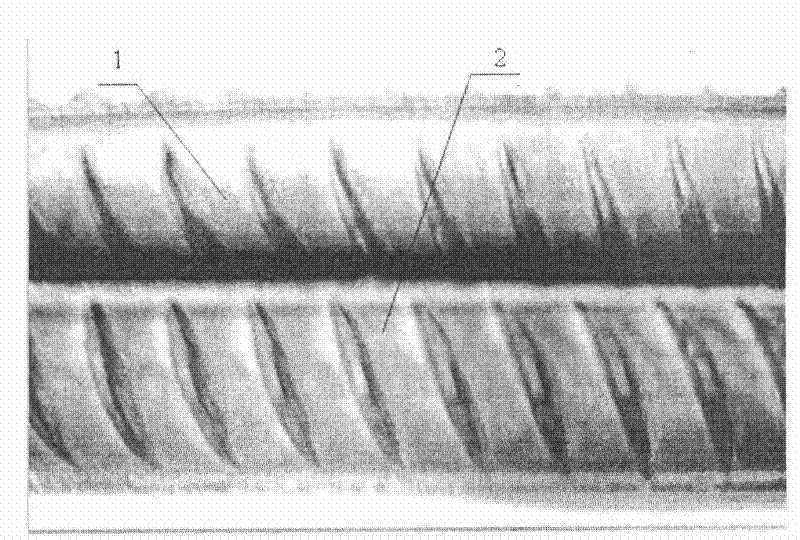

[0029] figure 1 The number 1 in shows the untreated rebar, figure 1 The symbol 2 in represents the threaded steel bar treated by the method of Embodiment 1 of the present invention. from figure 1 It can be seen from the figure that the surface gloss of the threaded steel bars treated by the anti-rust method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com