Technology for desorbing acid gas in methane

A technology of acid gas and biogas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of poor operation stability of the device, loss of effective components, poor operation stability, etc., achieve no corrosion of equipment, reduce consumption, and improve recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The raw material biogas 70 in the present embodiment is made up of the following components of volume percentage: 60% CH 4 , 39% CO 2 , the balance of other gases, the content of hydrogen sulfide is 1800mg / Nm 3 . The absorption solvent is composed of the following components in mass fraction: N-formylmorpholine 70%, N-acetylmorpholine 30%.

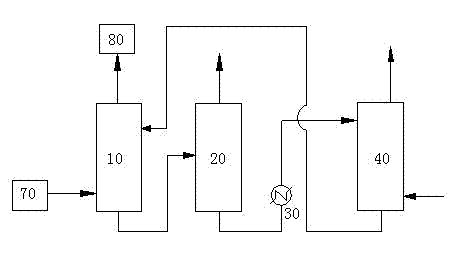

[0042] figure 1 It is a schematic flow chart of the method in this embodiment. First pass the raw material biogas 70 into the mixed absorption tower 10 for desulfurization and decarbonization. The pressure inside the mixed absorption tower 10 is 2.5MPa, the temperature is 25°C, and the volume ratio of the raw material biogas to the absorption solvent is 2-4:1. The obtained purified biogas 80 is drawn from the top of the mixed absorption tower 10 , while the absorbed absorption solvent is discharged from the bottom of the mixed absorption tower 10 . The absorbed absorption solvent first enters the atmospheric pressure gas-liquid...

Embodiment 2

[0045] The absorption solvent used in this embodiment is composed of the following components by mass fraction: 67-70% of N-formylmorpholine, 27-30% of N-acetylmorpholine, and 2-4% of water. The volume ratio of the raw biogas to the absorption solvent is 1-4:1, and the other conditions are the same as in Example 1. In the final purified and enriched product gas, CH 4 Content ≥ 96%, CO 2 Content ≤ 3%, H 2 S content≤5mg / Nm 3 , total sulfur content≤200mg / Nm 3 , Methane recovery rate ≥ 94%.

Embodiment 3

[0047] The absorption solvent used in this embodiment is composed of the following components in mass fraction: 96-98% of N-formylmorpholine, and 2-4% of water. The volume ratio of the raw biogas to the absorption solvent is 1-3:1, and the other conditions are the same as in Example 1. In the final purified and enriched product gas, CH 4 Content ≥ 96%, CO 2 Content ≤ 3%, H 2 S content≤5mg / Nm 3 , total sulfur content≤200mg / Nm 3 , Methane recovery rate ≥ 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com