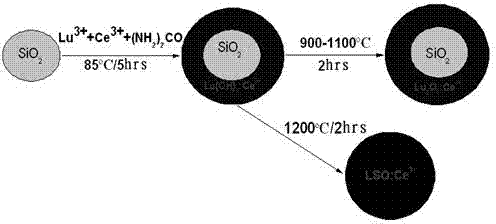

Preparation method of cerium ion-doped lutetium silicate powder by liquid phase package method at low temperature

A wrapping method, cerium ion technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of irregular morphology, low synthesis temperature and low calcination temperature of lutetium silicate, and achieve controllable particle size of powder, The effect of small powder particle size and low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

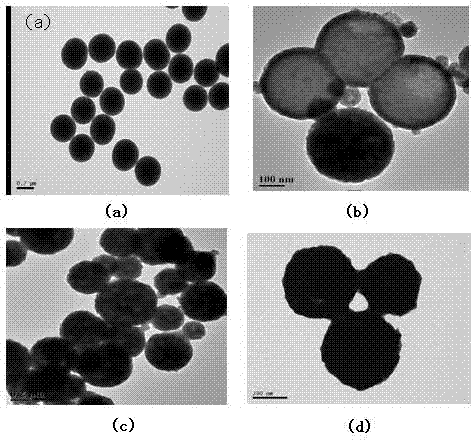

[0016] a. Add 250ml of absolute ethanol, 35ml of deionized water and 7ml of concentrated ammonia into a clean beaker in sequence. After mixing evenly, slowly drop into the mixed solution of 20ml tetraethyl orthosilicate and 200ml absolute ethanol, under stirring with a magnetic stirrer, seal the bottle mouth with a polyvinyl chloride film and react at a constant temperature of 85°C for 5h, then separate by centrifugation SiO in colloidal solution 2 The nanospheres were separated and dried in an oven at 100°C for 12 hours to obtain SiO with a particle size of 200nm. 2 Microspheres;

[0017] b. Weigh 0.1 g SiO2 2 Spherical particles were mixed with 500 ml deionized water and then ultrasonically dispersed for 15 min to obtain a sol-like liquid. Mix 1100 ml deionized water, 6.33 ml lutetium nitrate solution, 3.2 ml cerium nitrate solution and 38 g urea evenly. Pour the two solutions into a 3000 ml beaker, stir on a magnetic stirrer, and keep the solution temperature at 85°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com