Preparation method of octodecyl trimethyl ammonium bromide antibacterial solid paraffin

A technology of octadecyltrimethylammonium bromide and solid paraffin, which is applied in the directions of botanical equipment and methods, chemicals for biological control, biocides, etc., and can solve the problem of not finding octadecyltrimethylammonium Problems such as the preparation method of ammonium bromide antibacterial solid paraffin to achieve good antibacterial effect, less dosage and less toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

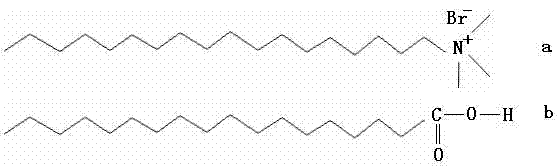

[0154] Example 1: a preparation method of octadecyltrimethylammonium bromide antibacterial paraffin wax (No. 50)

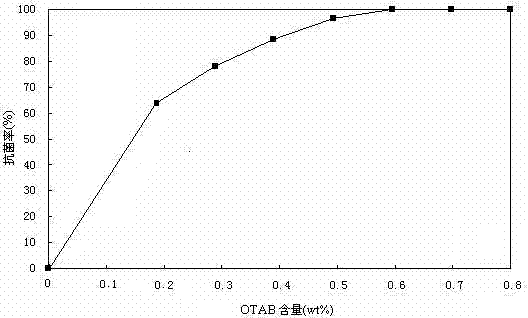

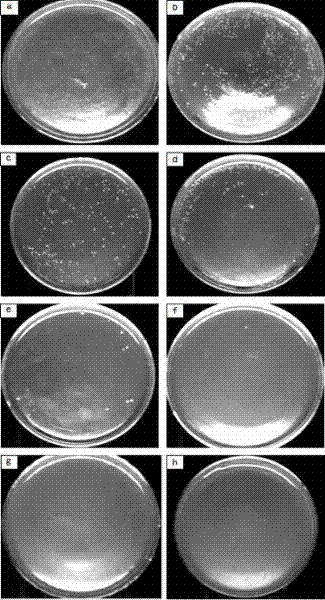

[0155] In this example, No. 50 solid paraffin was used as the raw material, octadecyltrimethylammonium bromide (OTAB) was used as the antibacterial agent, stearic acid was used as the OTAB dispersion modifier, and a two-step mixing method of low temperature and high temperature was adopted. OTAB is evenly dispersed in paraffin wax to prepare a kind of OTAB antibacterial paraffin wax (No. 50) with excellent antibacterial properties. The preparation process is carried out in the following 8 steps:

[0156] (1) Paraffin wax melting: Weigh a certain amount of solid paraffin and place it in a beaker. Use a universal electric furnace to slowly heat the solid paraffin until it melts, and finally effectively control and stabilize the melt temperature at 80-90°C. ;

[0157] (2) Weighing of stearic acid: according to the ratio of OTAB:stearic acid=1:5~10, w...

example 2

[0165] Example 2: A preparation method of octadecyltrimethylammonium bromide antibacterial paraffin wax (No. 52)

[0166] In this example, No. 52 paraffin wax is used as the raw material, and other reagents and preparation steps are exactly the same as those in Example 1.

[0167]

example 3

[0168] Example 3: A preparation method of octadecyltrimethylammonium bromide antibacterial paraffin wax (No. 54)

[0169] In this example, No. 54 solid paraffin is used as the raw material, and other reagents and preparation process steps are exactly the same as those in Example 1.

[0170]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com