Light-cured tetrahydrophthalic anhydridized tung oil acrylate resin and preparation method thereof

A technology of tetrahydrophthalic anhydride and acrylate, applied in the field of photocuring tetrahydrophthalic anhydride tung oil acrylate resin and its preparation, can solve the problem of limited application, adhesion, elasticity, gloss and weather resistance, no obvious advantages, and high toxicity of raw materials and other problems, to achieve the effect of improving curing speed, excellent weather resistance, and small curing volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

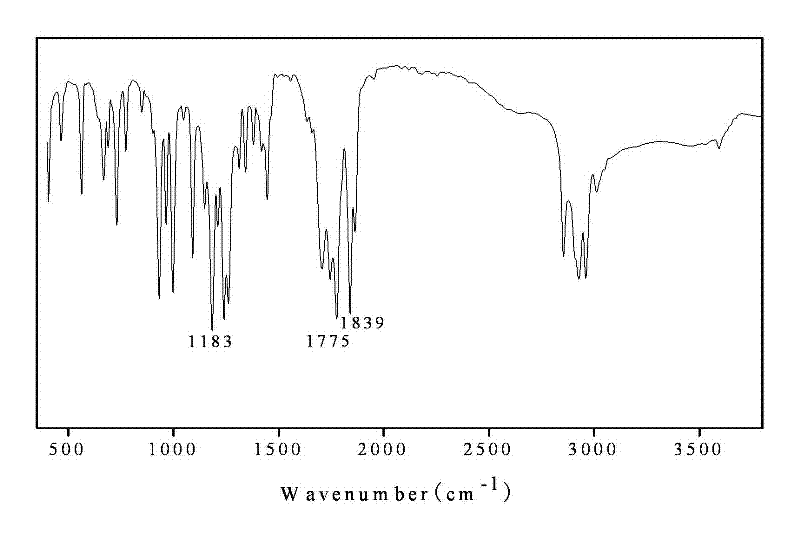

Examples

Embodiment 1

[0055] The preparation method of light-cured tetrahydrophthalic anhydride tung oil acrylate resin of the present invention, described preparation method comprises the following steps:

[0056] a. Using tung oil and tetrahydrophthalic anhydride as basic raw materials, the mass ratio between tung oil and tetrahydrophthalic anhydride is 100:45, first add 100g of tung oil weighed into the four-port reaction with agitator, thermometer and reflux condenser In the container, heat the oil bath to 65°C, then add 45g of tetrahydrophthalic anhydride weighed, raise the temperature to 180°C, and carry out the Diels-Alder reaction under this temperature condition, as the reaction proceeds, the intermediate product tetrahydrophthalic anhydride Tung oil, the intermediate product that generates is carried out along with reaction, and its acid value increases gradually, and when reacting to the acid value of intermediate product tetrahydrophthalic anhydride tung oil no longer changes, reaction f...

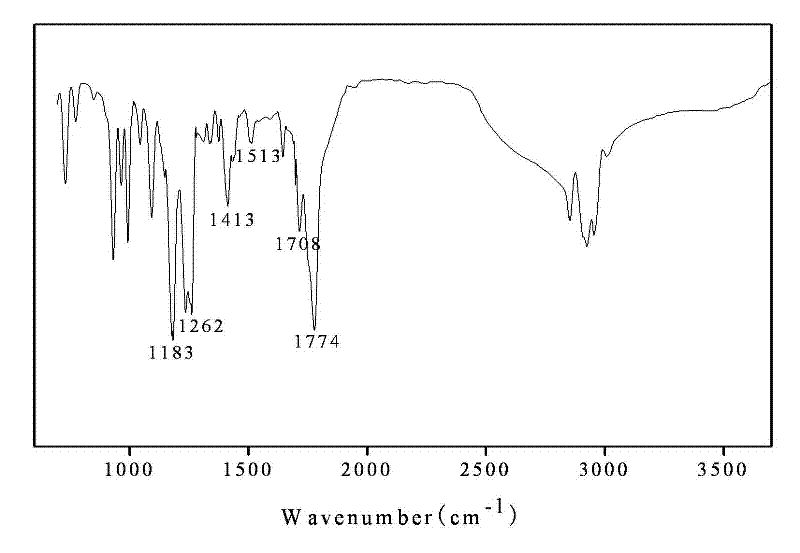

Embodiment 2

[0058] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0059] In step b: the reflux agent is 100 mL of xylene, the polymerization inhibitor is 0.1 g of p-methoxyphenol, 15 g of β-hydroxyethyl methacrylate is added, and the temperature is raised to 138 ° C for esterification reaction; 118.8 g of product are obtained : Tetrahydrophthalic anhydride tung oil methacrylate-β-hydroxyethyl ester resin (for the infrared analysis spectrum of this product, see image 3 ).

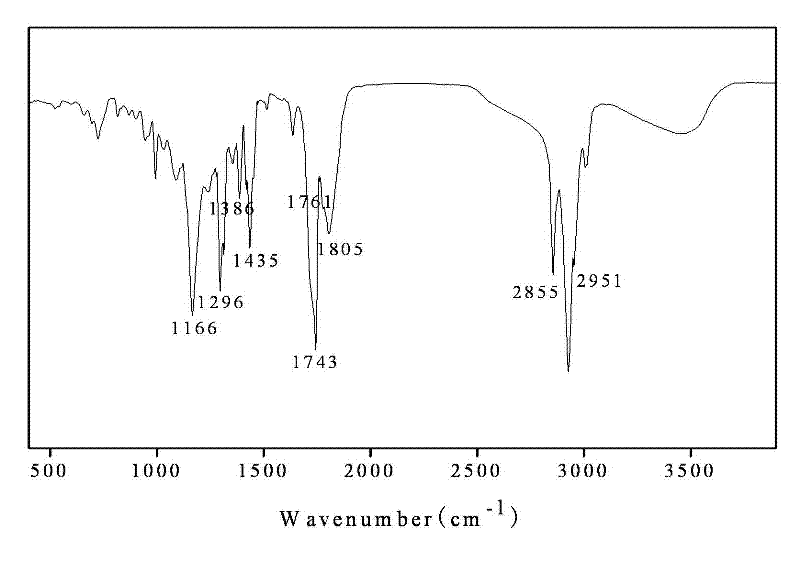

Embodiment 3

[0060] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0061] In step b: 100 mL of xylene as the refluxing agent, 0.1 g of nitrobenzene as the polymerization inhibitor, and 10 g of β-hydroxypropyl acrylate are added, and the temperature is raised to 138 ° C for esterification; 113.7 g of the product is obtained: tetrahydrophthalic anhydride Tung Oil Acrylate-β-Hydroxypropyl Ester Resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com