Method for preparing high-purity coenzyme Q10 in large scale

A high-purity, coenzyme technology, applied in quinone separation/purification, organic chemistry, bulk chemical production, etc., can solve the problems of low yield and purity, pending research, high cost, etc., to achieve high product quality, reduce production costs, Effect of production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

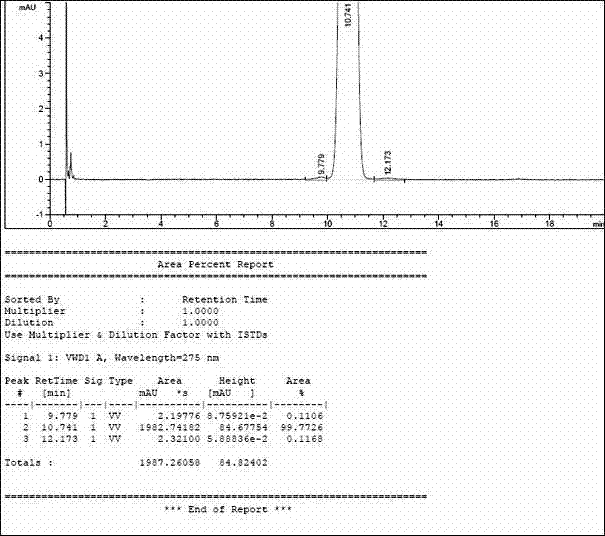

[0048] Coenzyme Q10 dried cells 10kg, content 26.81mg / g, particle size 80-120 mesh, moisture 5.6%. Under the pressure of 24.5Mpa, temperature of 35℃, and the amount of entrainer (n-hexane) 1.3ml / g, the 2 Supercritical extraction was performed for 45 minutes to obtain 2.5L of extract with a content of 106.54 mg / ml. Add 1.5L sodium hydroxide solution with a concentration of 0.35mol / L and stir for 40 min, let it stand for 2.5hr, after the layer is completely separated, let go of the lower layer, then add 2L of purified water and stir for 10 min, let it stand for 30 minutes, and let go of the lower layer , The upper layer is dehydrated by a desiccator (anhydrous sodium sulfate 25g) to obtain 2.3L of upper column liquid with a content of 113.30mg / ml. Apply the upper column liquid to a silica gel chromatography column at (effective amount: filler) 1:10, eluting with 2.5% (V / V) ethyl acetate in n-hexane, and obtain the main eluate by TLC chromatography. At the same time, the eluates ...

Embodiment 2

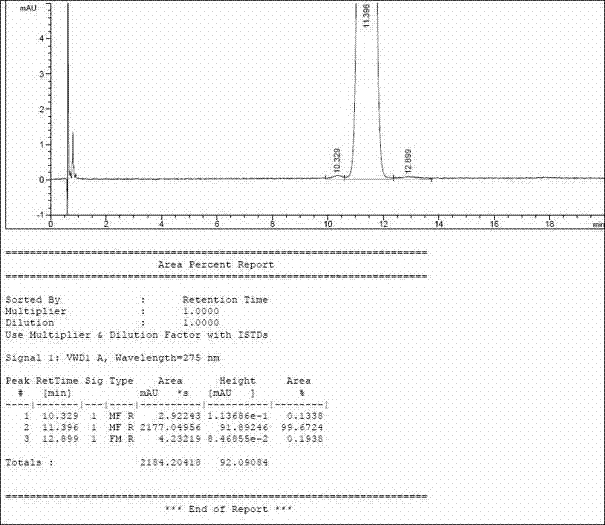

[0050] Coenzyme Q10 dry cell 100kg, content 30.13mg / g, particle size 130-200 mesh, moisture 5%. Under the pressure of 20.5Mpa, the temperature of 30℃, and the amount of entrainer (ether) 1.5ml / g through CO 2 Supercritical extraction for 30 minutes, 25.76L of extract was obtained, with a content of 115.65 mg / ml. Add 26.25L, 0.2mol / L sodium hydroxide solution and stir for 40 min, and let it stand for 2hr. After the layer is completely separated, let go of the lower layer, then add 20L purified water and stir for 10 min, let it stand for 30 minutes, let go of the lower and upper layers After dehydration in a desiccator (28g anhydrous sodium sulfate), 24.4L of upper column liquid was obtained, with a content of 119.70mg / ml. Put the upper column liquid on the column according to (effective amount: filler) 1:5, eluting with 1.5% (V / V) isopropyl ether in petroleum ether, and obtain the main eluate by TLC chromatography. At the same time, separately collect the eluates from the front ...

Embodiment 3

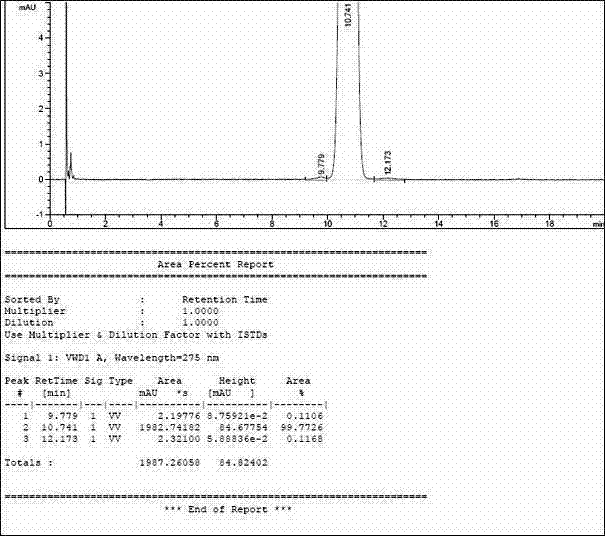

[0052] The chromatographic column of Example 1 was eluted with 2 to 3 times ethanol, and then equilibrated with 1 to 2 times petroleum ether, and set aside.

[0053] Coenzyme Q10 dried cells 20kg, content 16.50mg / g, particle size 60-100 mesh, moisture 6%. Under the pressure of 27.0Mpa, temperature of 33℃, and the amount of entrainer (petroleum ether) 1.0ml / g 2 Supercritical extraction was performed for 50 minutes to obtain 3.8L extract with a content of 85.79 mg / ml. Add 2.5L of sodium hydroxide solution with a concentration of 0.25mol / L and stir for 40 min, and let it stand for 2.5hr. After the layer is completely separated, let go of the lower layer, then add 2.5L of purified water and stir for 10 min, let it stand for 30 minutes, and let go The lower layer and the upper layer are dehydrated by a desiccator (38g anhydrous sodium sulfate) to obtain 3.7L of upper column liquid with a content of 86.10mg / ml. The upper column liquid is added to the chromatographic column that has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com