Method for forming aluminum coating on surface of neodymium iron boron magnet

A technology of neodymium iron boron and magnets, which is applied in the direction of surface coating liquid devices, coatings, special surfaces, etc., can solve the problem of no magnetic shielding effect, etc., and achieve the effect of low cost, simple process and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

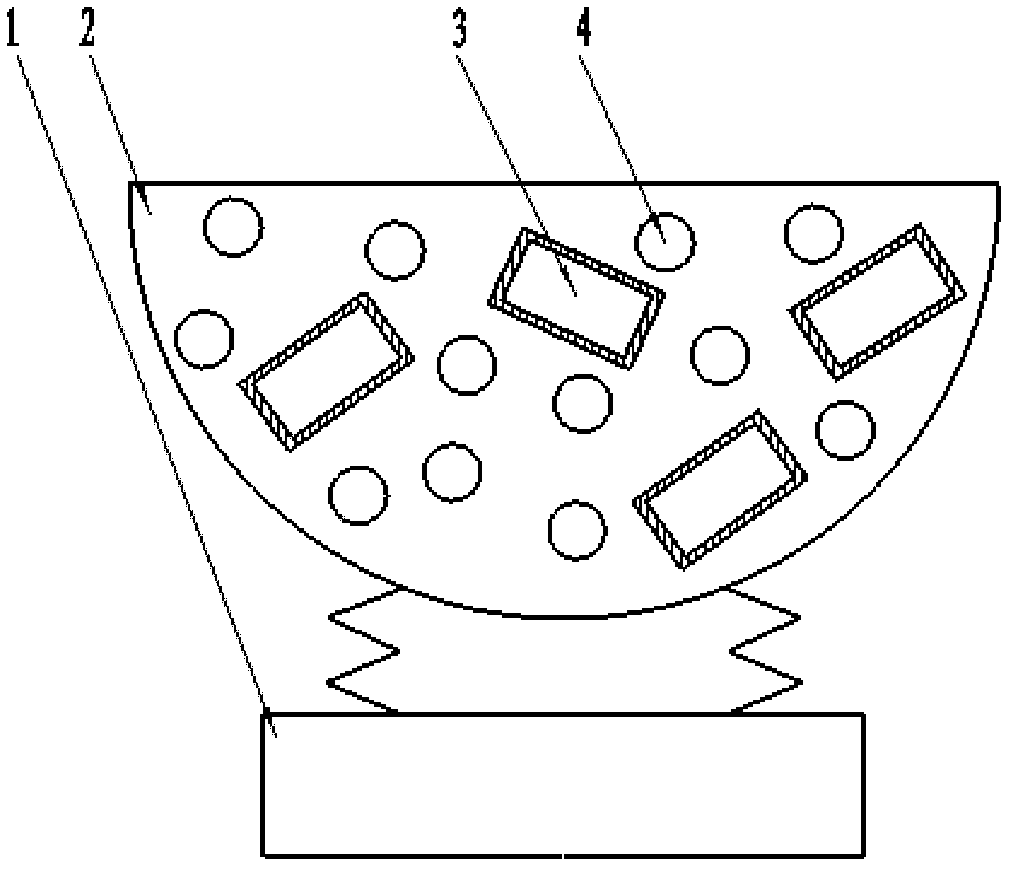

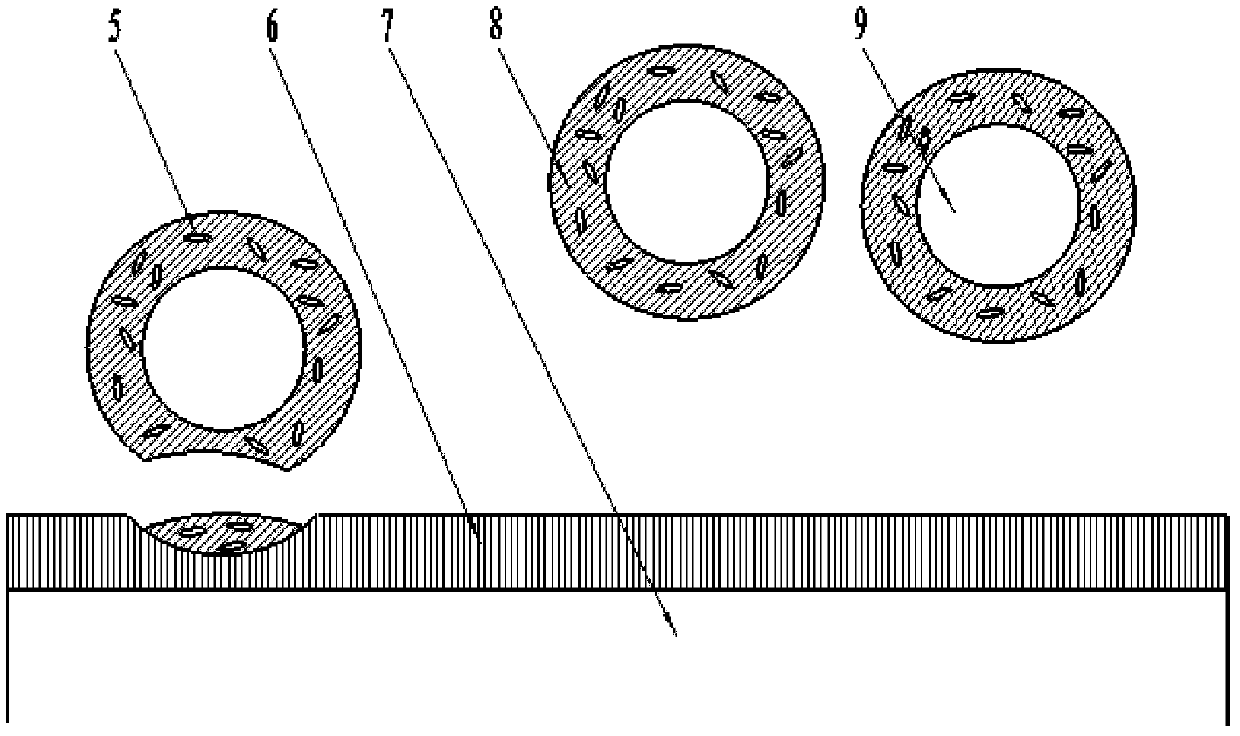

[0035] Take 1 kg of 5*3.5*2mm NdFeB magnet workpiece, chamfer it in the chamfering machine, and then perform rolling sandblasting in the sandblasting machine for 20 minutes. After the sample was taken out, it was simply cleaned, soaked in the phosphating solution for 30s, and then dried.

[0036] On the other hand, 30 kg of steel balls with a diameter of 1.5 mm were put into the vibration container. Weigh out 12g of epoxy resin and 28g of aluminum powder with an average particle size of 28μm with a balance, and mix them evenly. Start the power supply, and when the vibrating container and steel balls are in a vibrating state, slowly put in the mixed powder of epoxy resin and aluminum, and finally put in all of them. Continue to vibrate for about half an hour until the mixed powder is mixed with steel balls.

[0037] Use a balance to measure out 30g of acrylic resin and 180g of thinner (its composition is as above), pour into an empty container and mix and stir until the acryl...

Embodiment 2

[0041] Take 1 kg of 5*3.5*2mm NdFeB magnet workpiece, chamfer, sandblast, and phosphate according to the method in Example 1.

[0042] On the other hand, 40 kg of steel balls with a diameter of 1.5 mm were put into the vibration container. Weigh 28g of epoxy resin and 28g of aluminum powder with an average particle diameter of 10 microns with a balance, and mix them uniformly. According to the method in Example 1, the mixed powder and steel balls were mixed evenly.

[0043] In the same manner as in Example 1, a liquid resin solution was formulated and mechanically plated and baked for curing. Repeat the treatment process 3 times to finally obtain the aluminum powder coating.

[0044] The average thickness of the coating is about 15 microns, and it does not rust for 120 hours in the SST test, and does not rust for 48 hours in the PCT test.

Embodiment 3

[0046] Take 1 kg of 5*3.5*2mm NdFeB magnet workpiece, chamfer, sandblast, and phosphate according to the method in Example 1.

[0047] Put 50 kg of steel balls with a diameter of 0.8 mm into the vibrating container. Weigh 84g of epoxy resin and 28g of aluminum powder with an average particle diameter of 28 microns with a balance, and mix them uniformly. Mix the mixed powder and steel balls according to the method in Example 1.

[0048] Measure 20g of acrylic resin and 200g of thinner with a balance, mix and prepare the liquid resin in the same manner as in Example 1, and coat the magnet workpiece.

[0049] After performing mechanical plating in the same manner as in Example 1, bake in an oven at a temperature of 160° C. for half an hour. Carry out the same treatment process as above three times to the magnet workpiece, and finally obtain the aluminum powder coating.

[0050] The average thickness of the coating is about 10 microns. After the SST test, there is no rust in 72...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com