Manufacturing method of lithium iron phosphate-cobalt acid lithium composite anode plate of lithium ion battery

A lithium-ion battery and lithium iron phosphate technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as short cycle life, low specific capacity, and poor high-current discharge effect, and achieve short cycle life, prolongation, and improvement Discharge specific capacity, the effect of improving the effect of large current discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

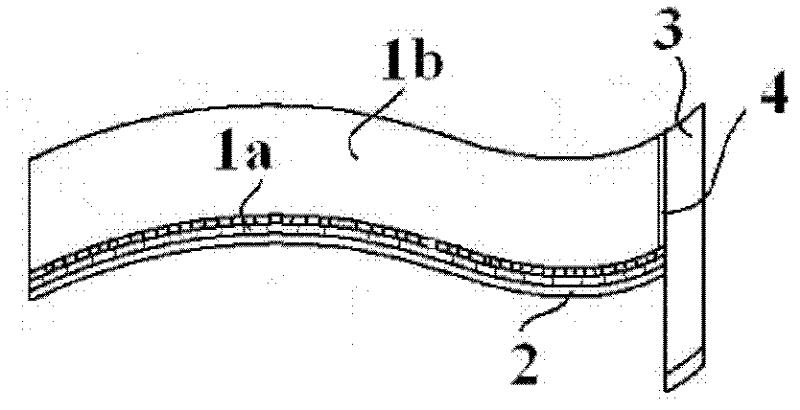

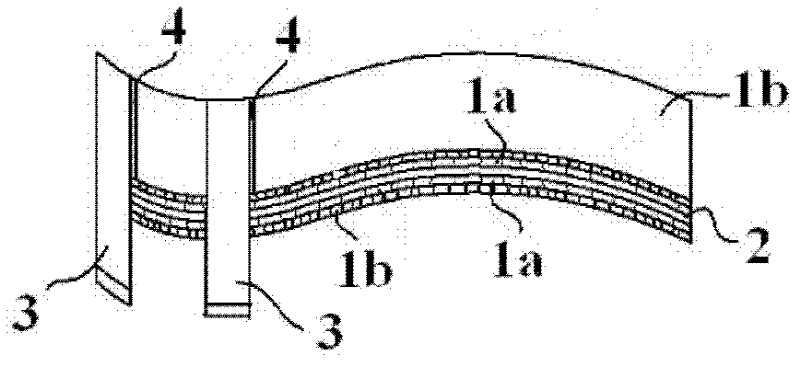

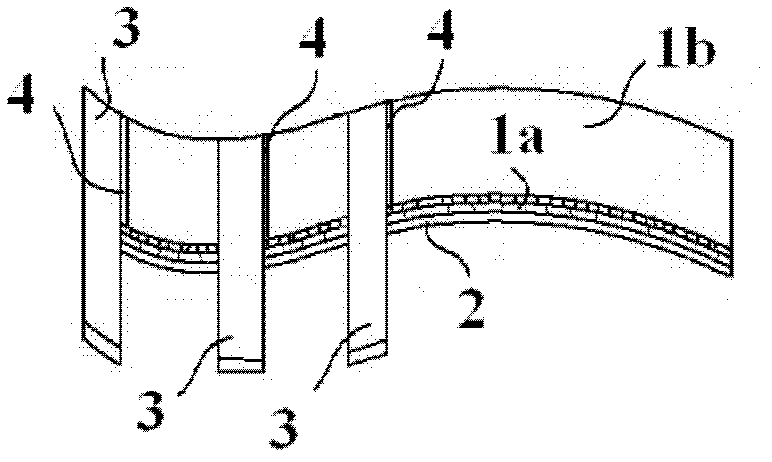

[0035] A method for manufacturing a lithium iron phosphate-lithium cobaltate composite positive pole piece for a lithium ion battery, the steps of which are:

[0036] A. The first layer of positive electrode active material slurry 1a is prepared by the following steps: Step 1: Mix the nano-lithium cobaltate positive electrode active material and the nano-Super-C conductive agent by ball milling at a mass ratio of 1:5 to obtain cobalt acid Lithium active material mixture; the second step, mix the mixture obtained in the first step with the polyvinylidene fluoride binder according to the mass ratio of 1:100; the third step, mix the mixture obtained in the second step with the content of 1% sodium carboxymethylcellulose (thickener) is mixed according to the mass ratio of 1:10 to 1:5, and N-methylpyrrolidone (NMP) solvent equivalent to 50% of the mass of polyvinylidene fluoride is added Ball milling and mixing uniformly; in the fourth step, adding 10% by mass percentage to the mix...

Embodiment 2

[0041] A method for manufacturing a lithium iron phosphate-lithium cobaltate composite positive pole piece for a lithium ion battery, the steps of which are:

[0042] A. The first layer of positive electrode active material slurry 1a is prepared by the following steps: Step 1: Mix the positive electrode active material of nano-lithium cobaltate and nano-Super-C conductive agent by ball milling in a mass ratio of 3:5 to obtain cobalt acid Lithium active material mixture; in the second step, the mixture obtained in the first step and the polyvinylidene fluoride binder are uniformly mixed in a ratio of 1.5:100 according to the mass ratio; in the third step, the content of the mixture obtained in the second step and 1% sodium carboxymethyl cellulose (thickener) is mixed according to the mass ratio of 1:66, and N-methylpyrrolidone (NMP) solvent equivalent to 50% of the mass of polyvinylidene fluoride is added and mixed uniformly; The fourth step is to add 15% by mass to the mixture...

Embodiment 3

[0047] A method for manufacturing a lithium iron phosphate-lithium cobaltate composite positive pole piece for a lithium ion battery, the steps of which are:

[0048] A. The first layer of positive electrode active material slurry 1a is prepared by the following steps: Step 1: Mix the positive electrode active material of nano-lithium cobaltate and nano-Super-C conductive agent by ball milling in a mass ratio of 4:5 to obtain cobalt acid Lithium active material mixture; the second step, the mixture obtained in the first step and the polyvinylidene fluoride binder are uniformly mixed in a ratio of 2.5:100 according to the mass ratio; the third step, the content of the mixture obtained in the second step and 1% sodium carboxymethyl cellulose (thickener) is mixed according to the mass ratio of 1.5:10, and N-methylpyrrolidone (NMP) solvent equivalent to 50% of the mass of polyvinylidene fluoride is added and mixed uniformly by ball milling; In the fourth step, add 20% by mass to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com