Flexible solar cell photovoltaic component made with flexible substrate

A technology for solar cells and photovoltaic modules, applied in photovoltaic power generation, electrical components, circuits, etc., can solve problems such as reducing fill factor, destroying battery electrical performance, increasing leakage current, etc., to reduce composite, photoelectric conversion efficiency and cost performance. Improved, high temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0049] Example 1 Process for preparing flexible amorphous silicon solar cells:

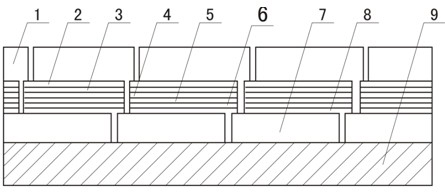

[0050] A 0.5 mm thick stainless steel sheet template (or template for short) is used, on which there are light-transmitting holes (not shown in the figure) distributed in the front electrode pattern, including current guiding holes (or drainage holes for short) and confluence holes ;

[0051] The polyamic acid slurry prepared according to the molar ratio formula;

[0052] The polyamic acid paste is screen-printed on the template, and treated at a high temperature of 350°C to obtain a uniform and transparent modified polyimide substrate with light-transmitting through holes, including current guiding holes and confluence holes;

[0053] Depositing a layer of resistivity on a modified polyimide substrate by magnetron sputtering at a temperature of 350°C

[0054] 15Ω / , ZnO transparent conductive film with light transmittance of 93%;

[0055] No need to scribe ZnO transparent conductive film wit...

example 2

[0063] A 0.5 mm thick stainless steel sheet template (or template for short) is used, on which there are light-transmitting through holes distributed in the front electrode pattern (not shown in the figure), including the preparation and modification of current guiding holes and confluence holes; manufacturing steps In the same example 1, only the modified PI substrate production formula, the deposition temperature of the amorphous silicon film and the thickness of each layer of film are changed:

[0064] According to 3,3`-trifluorodimethyl-4,4`diaminodiphenylmethane: N,N-dimethylacetamide: 2,3,3`,4`-biphenyltetracarboxylic dianhydride= Add the diamine monomer 3,3`-trifluorodimethyl-4,4`diaminodiphenylmethane into the N,N-dimethylacetamide DMAc solution at a molar ratio of 1.0 : 47 : 1.0. Into nitrogen, after stirring at room temperature for 5 minutes, began to add 2,3,3`,4`-biphenyltetracarboxylic dianhydride a-BPDA. Under nitrogen protection, stirred at room temperature for ...

example 3

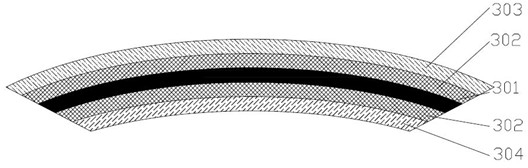

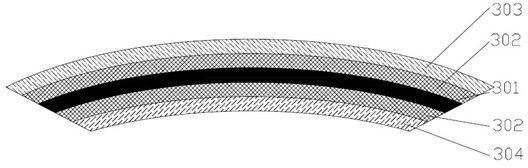

[0068] The stainless steel sheet template, the modified PI substrate are the same as Example 2, the manufacturing steps of the flexible amorphous silicon solar cell chip are the same as Example 1, and the packaging steps are as follows:

[0069] 1) Use a transparent flexible front plate polymer film (such as polyvinyl fluoride, fluorinated ethylene propylene copolymer, etc.) with a thickness of 25 μm to 75 μm and an adhesive (such as EVA, PE, etc.) layer plane.

[0070] 2) Press-bond the tin-coated copper tape to both ends of the battery chip.

[0071]3) The battery sheet coated with tin strip and the supporting adhesive / transparent flexible front plate polymer film are sent to the hot press. At the same time, the adhesive (such as EVA, PE, etc.) ), with a thickness of 25 μm to 75 μm flexible backplane polymer film (one layer of polymer film or multi-layer organic-inorganic composite material). According to the design requirements of the BIPV module length, the upper two lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com