Condensing device

A technology for condensing devices and condensers, which is applied in the field of ammonia condensing devices and condensing devices, can solve the problems of unsuitable condensers, high cost of improvement, and large medium flow rate, etc., to delay corrosion speed, avoid vibration and erosion, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

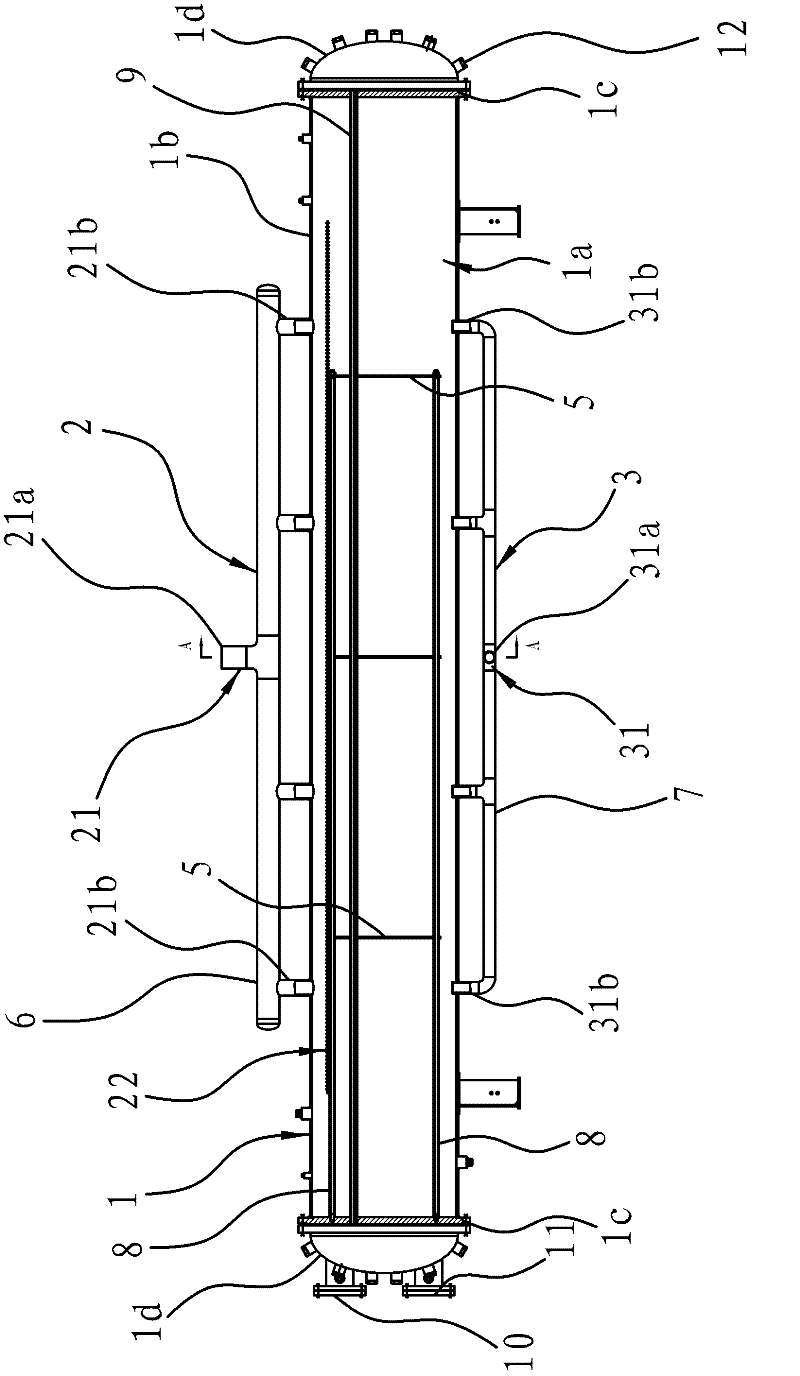

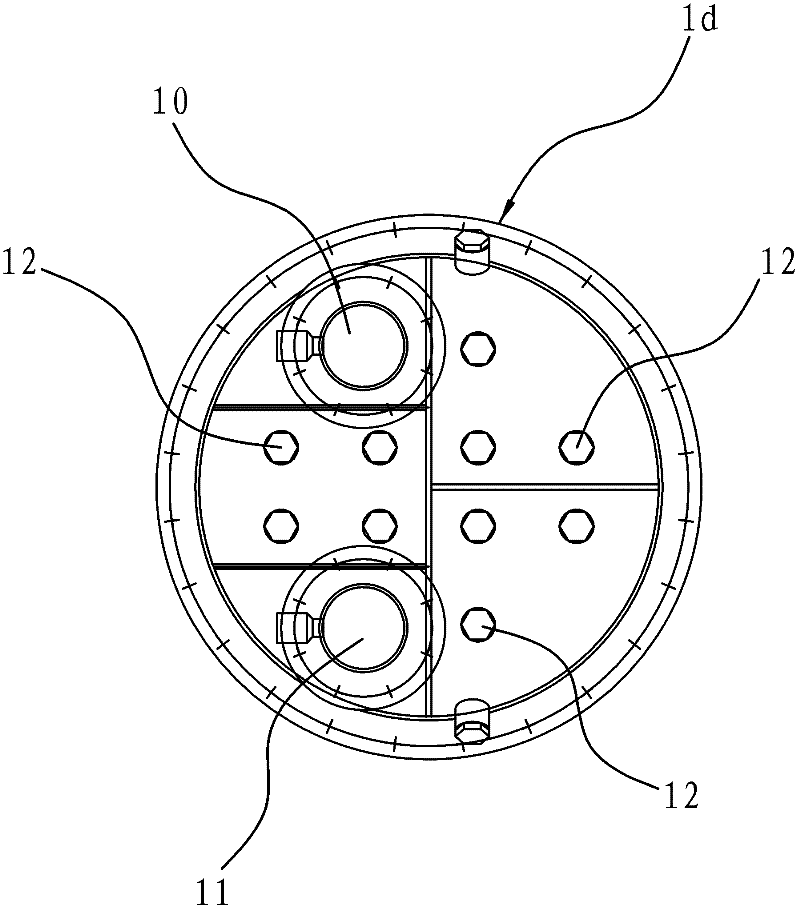

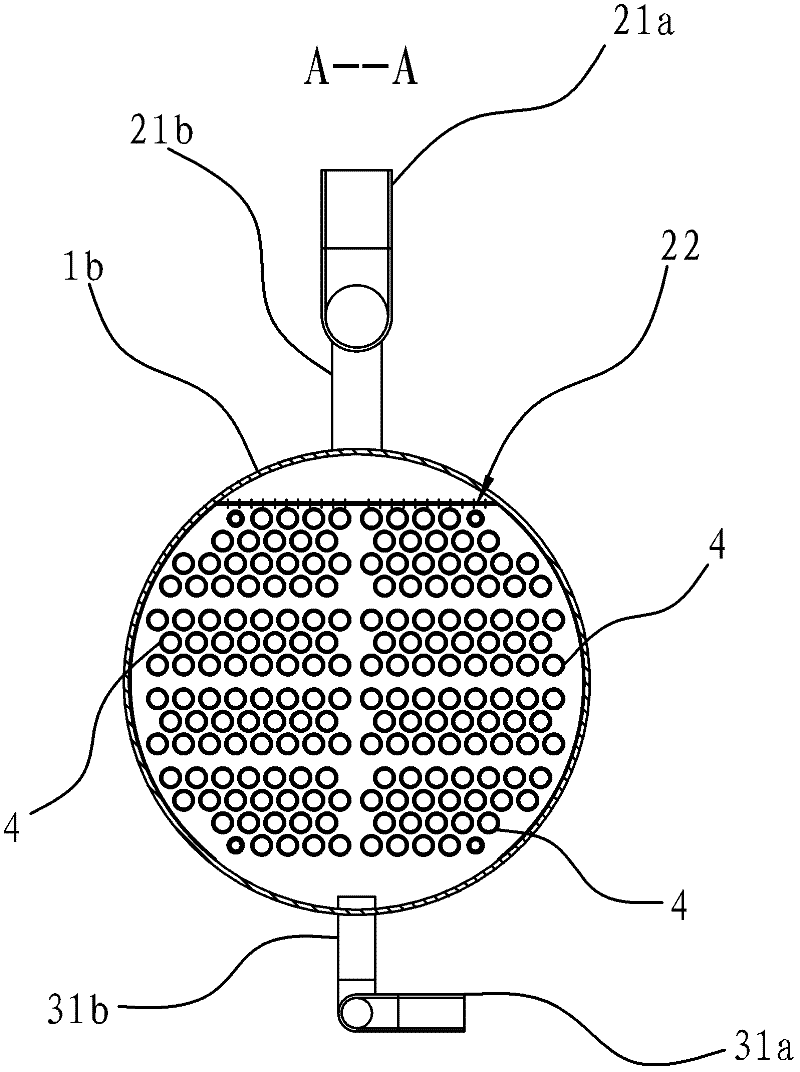

[0037] Such as figure 1 , figure 2 with image 3 As shown, the condensing device includes a condenser body 1 with a cavity 1a inside, an air intake mechanism 2 connected to the air inlet on the upper side of the body 1 , and a liquid outlet mechanism 3 connected to the liquid outlet on the lower side of the body 1 . The body 1 includes a cylindrical shell 1b, a tube plate 1c fixedly connected to both ends of the shell 1b, and a front tube box 1d and a rear tube box 1d respectively connected to the outer sides of the two tube plates 1c. The cavity 1a in the body 1 is provided with several heat exchange tubes 4 and support plates 5 for supporting the heat exchange tubes 4, wherein the axial direction of the heat exchange t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com