Drying system for flexible circuit board

A flexible circuit board and drying system technology, applied in the field of drying systems, can solve problems such as surface indentation or discount, gold surface scratches, and decline in yield rate, so as to achieve the effect of improving connectivity and ensuring drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

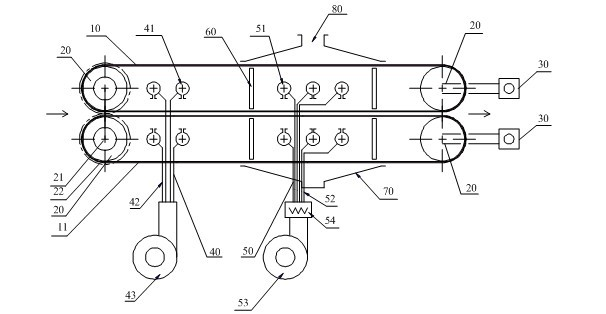

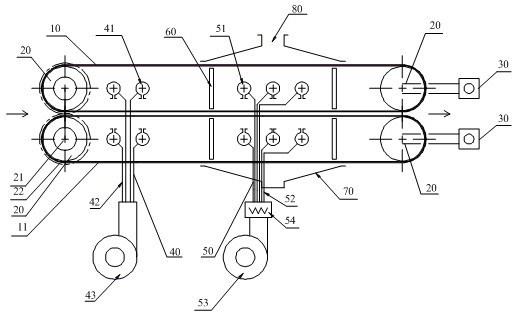

[0023] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

[0024] like figure 1 As shown, a drying system for flexible circuit boards, including:

[0025] Two conveying devices are made of polytetrafluoroethylene material, including: an upper conveyor belt 10 and a lower conveyor belt 11 that are close to each other and parallel;

[0026] Four rotating shafts 20 are respectively arranged at both ends of the conveyor belt for driving the transmission of the conveyor;

[0027] The deviation mechanism 30 is arranged on the rotating shaft 20 and is used to adjust the tension of the upper conveyor belt 10 and the lower conveyor belt 11;

[0028] The cold air device 40 is used to blow out cold air, including: a cold air blower 43 and a cold air knife 41, which are connected with a cold air blower hose 42 between the cold air blower 43 and the cold air knife 41;

[0029] Hot air device 50, is used for blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com