Turbocharger and working method thereof

Technology of a turbocharger, working method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

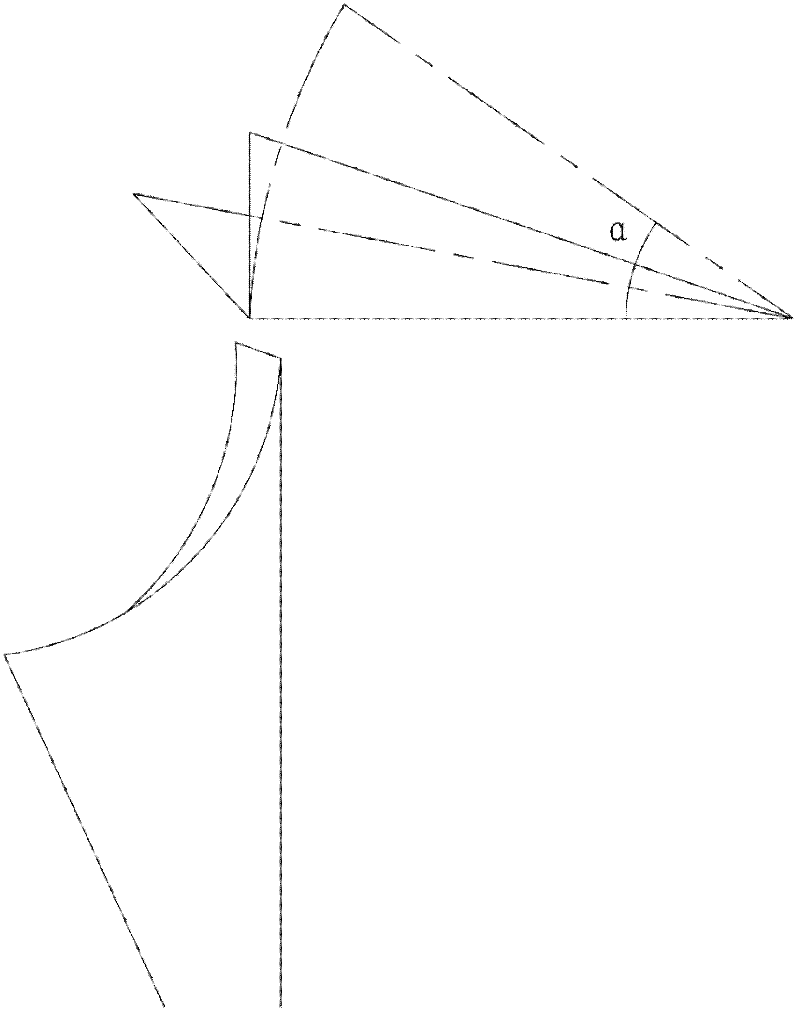

[0027] See Figure 4-8 The turbocharger of the present embodiment includes: a volute 1 arranged in the turbine casing, a volute fixed in the volute 1 and set on the outer periphery of the turbine impeller 10 for automatically controlling the nozzle cut-off according to the working conditions of the engine. area of the nozzle ring assembly.

[0028] The nozzle ring assembly includes: a nozzle ring 4, a plurality of long nozzle blades 2 symmetrically distributed on the outer surface of the nozzle ring 4, and a pair of adjacent long nozzle blades arranged on the nozzle ring 4. The chute 11 between the nozzle blades 2, the movable short blade 3 arranged in the chute 11 and suitable for moving back and forth in a straight line along the nozzle airflow direction, the linkage ring 5 concentrically arranged on the inner surface of the nozzle ring 4, The chute holes 51 corresponding to the chute 11 distributed on the linkage ring 5, the three arc-shaped guide grooves 52 distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com