Method for manufacturing low-cost high-toughness X70 steel spiral submerged arc welded pipe

A technology of submerged arc welded pipe and manufacturing method, which is applied in the field of low-cost and high-toughness X70 steel spiral submerged arc welded pipe manufacturing, can solve the problems of high cost and high alloy content of pipeline steel, and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

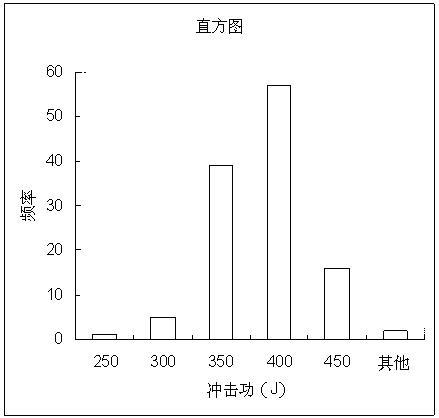

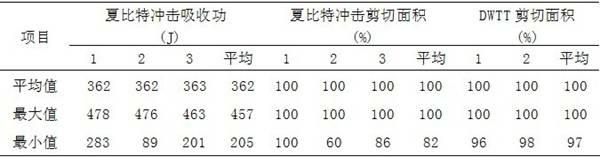

Image

Examples

Embodiment

[0017] The pipe diameter is Φ914mm, the wall thickness is 14.3mm, and the chemical composition is C 0.05~0.07%, Si 0.16~0.21%, Mn 1.49~1.59%, Cr 0.20~0.23%, Ni 0.014~0.019%, Al 0.029~0.054% , Cu 0.007~0.024%, Nb 0.030~0.046%, V 0.015~0.049%, Ti 0.012~0.021%, P 0.005~0.012%, S 0.001~0.001%, B 0.0001~0.0003%, N 0.0024~0.0085%, The X70 controlled-rolled steel plate with the quantity of iron is used to manufacture spiral submerged arc welded pipes. The manufacturing process is as follows:

[0018] The coils are uncoiled and leveled.

[0019] Edge milling: first rough milling, milling off the width of the plate edge by 0-10mm; then fine milling X-shaped groove, that is, the two butt-joint edges of the steel plate are respectively cut out with a blunt edge size of 8±1mm and a groove angle of 35° °~40° groove, the two sides of the steel plate are butted to form an X-shaped groove of 70°~80°.

[0020] Pre-bending: Pre-bend the delivery side and free side of the coiled plate on the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com