Preparation method of chemical solution of terbium-doped tungsten molybdate green fluorescent microcrystalline

A technology of tungstomolybdate and green fluorescence, which is applied in chemical instruments and methods, luminescent materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

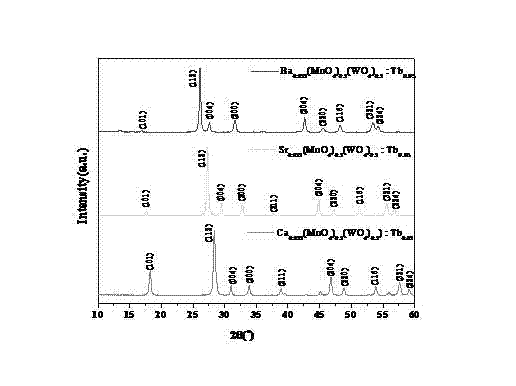

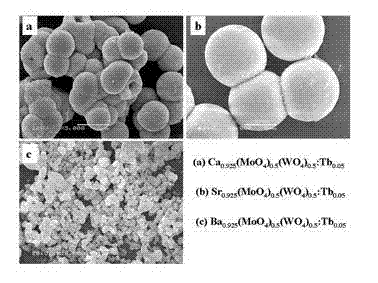

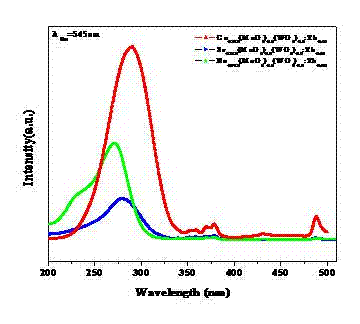

[0018] Example 1: Ca 0.975 (WO 4 ) 0.5 (MoO 4 ) 0.5 :Tb 3+ 0.05 Preparation of microcrystals

[0019] According to a certain amount of target system Ca 0.975 (WO 4 ) 0.5 (MoO 4 ) 0.5 :Tb 3+ 0.05 The molar ratio of the raw materials required for microcrystals, measure the corresponding volume of Ca(NO 3 ) 2 and TbCl 3 solution in a polytetrafluoroethylene beaker, and then add the corresponding amount of Na 2 WO 4 and Na 2 MoO 4 Solution, stirred at room temperature for 15-30 minutes, then put the polytetrafluoroethylene beaker into the autoclave. After hydrothermal reaction at 80-180° C. for 15-30 hours, naturally cool to room temperature. The precipitate is centrifuged, washed with deionized water, and then dried at 100-150°C to obtain Ca 0.975 (WO 4 ) 0.5 (MoO 4 ) 0.5 :Tb 3+ 0.05 Microcrystalline.

Embodiment 2

[0020] Example 2: Ba 0.975 (WO 4 ) 0.5 (MoO 4 ) 0.5 :Tb 3+ 0.05 Preparation of microcrystals

[0021] In addition to Ca(NO 3 ) 2 replaced by Ba(NO 3 ) 2 Outside, all the other press embodiment 1 technique, prepare Ba 0.975 (WO 4 ) 0.5 (MoO 4 ) 0.5 :Tb 3+ 0.05 Microcrystalline.

Embodiment 3

[0022] Example 3: Sr 0.975 (WO 4 ) 0.5 (MoO 4 ) 0.5 :Tb 3+ 0.05 Preparation of microcrystals

[0023] In addition to Ca(NO 3 ) 2 Replaced by Sr(NO 3 ) 2 Outside, all the other press embodiment 1 technique, prepare Sr 0.975 (WO 4 ) 0.5 (MoO 4 ) 0.5 :Tb 3+ 0.05 Microcrystalline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com