Silicate grout for deep water

A technology of cement slurry and cement, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems affecting the performance of cement slurry in the sealing section, accidents, and increased workload of cementing operations, so as to reduce the cementing time. Coagulation time, convenient cementing operation, controllable and adjustable thickening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, the preparation of portland cement slurry

[0031] The formula is: 1.20 Jiahua G-grade cement 100Kg, South China Sea deep sea water 100Kg, a mixture of ultra-fine slag powder and ultra-fine G-grade cement 25Kg (the mass-number ratio of ultra-fine slag powder and ultra-fine G-grade cement is 2 : 3), potassium tartrate 0.1Kg, calcium lignosulfonate (Jingzhou Jiahua Science and Technology Co., Ltd.) and sodium polystyrene sulfonate (number average molecular weight is 5000g / mol, Jingzhou Jiahua Science and Technology Co., Ltd.) mixture 3Kg (wherein , the mass fraction ratio of calcium lignosulfonate and sodium polystyrene sulfonate is 2:1), hollow calcium borosilicate microbeads (its density is 0.44g / cm 3 ) 34Kg, 2-acrylamide-2-methylpropanesulfonic acid-acrylamide copolymer (number average molecular weight is 100000g / mol) 5Kg.

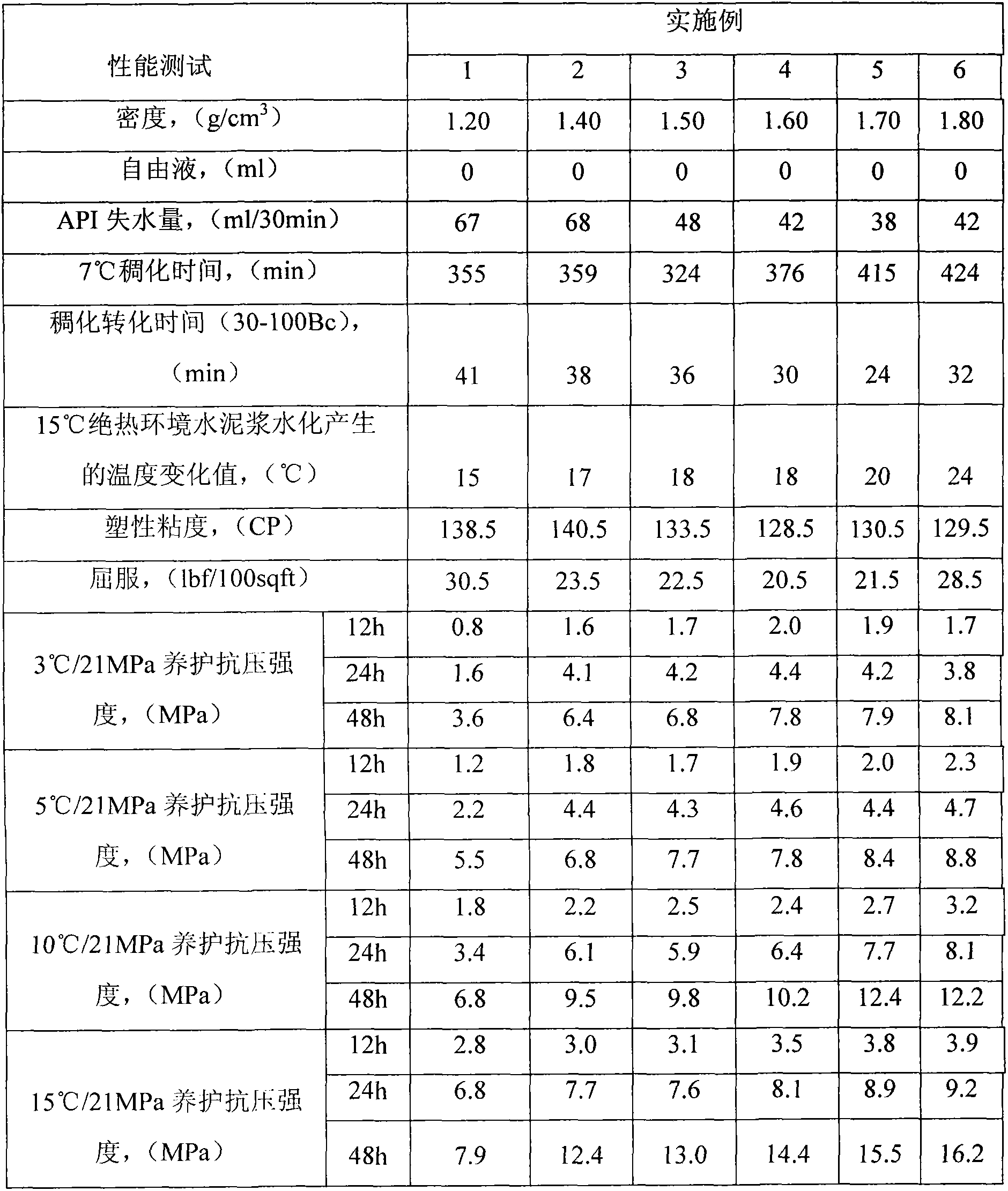

[0032] Mix the above-mentioned components evenly to obtain Portland cement slurry, and perform a performance test according to the ...

Embodiment 2

[0033] Embodiment 2, the preparation of portland cement slurry

[0034] The formula is: 100Kg of 1.40 Jiahua G-grade cement, 70Kg of China Bohai deep sea water, 20Kg of a mixture of ultra-fine slag powder, ultra-fine G-grade cement and sodium sulfate (among them, ultra-fine slag powder, ultra-fine G-grade The mass fraction ratio is 2: 3: 1), the mixture 2Kg of calcium lignosulfonate (Jingzhou Jiahua Technology Co., Ltd.) and sodium carbonate (wherein, the mass fraction ratio of calcium lignosulfonate and sodium carbonate is 1: 1), hollow calcium borate silicon borate microbeads (its density is 0.44g / cm 3 ) 18Kg, acrylamide-sodium acrylate copolymer (the number average molecular weight is 2000000g / mol) 4Kg.

[0035] Mix the above-mentioned components evenly to obtain Portland cement slurry, and perform a performance test according to the deep water cementing test standard API10B-3-2004. The performance test results are shown in Table 1.

Embodiment 3

[0036] Embodiment 3, the preparation of portland cement slurry

[0037] The formula is: 1.50 Jiahua G grade cement 100Kg, fresh water 60Kg, superfine slag powder, superfine G grade cement and potassium chloride mixture 10Kg (among them, the mass of superfine slag powder, superfine G grade cement and potassium chloride Parts ratio is 2: 3: 1), calcium lignosulfonate (Jingzhou Jiahua Technology Co., Ltd.) and sodium silicate mixture 1Kg (wherein, the mass-number ratio of calcium lignosulfonate and sodium silicate is 1 : 1), hollow calcium borosilicate microbeads (its density is 0.44g / cm 3 ) 13Kg, acrylamide-sodium acrylate copolymer (number average molecular weight 200000g / mol) 3Kg.

[0038] Mix the above-mentioned components evenly to obtain Portland cement slurry, and perform performance tests on it according to the deep water cementing test standard API10B-3-2004. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com