High-strength antistatic heat-conductive PPA (Polyphthalamide) material and preparation method of same

An anti-static, high-strength technology, applied in the field of high-strength anti-static and thermally conductive PPA materials and its preparation, can solve the problems of poor electrical properties, thermal properties, and strength of PPA, and achieve low cost, simple process, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

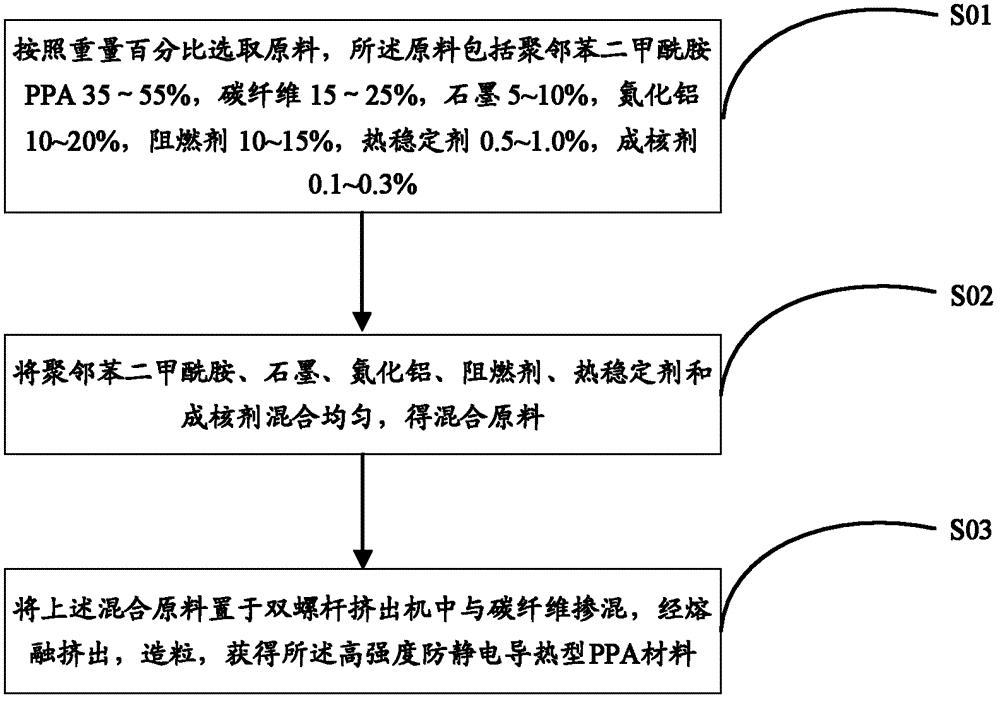

[0035] see figure 1 , showing a method for preparing a high-strength antistatic heat-conducting PPA material according to an embodiment of the present invention, the method comprising the following steps:

[0036] S01: Select raw materials according to weight percentage, the raw materials include polyphthalamide PPA35-55%, carbon fiber 15-25%, graphite 5-10%, aluminum nitride 10-20%, flame retardant 10-15% , heat stabilizer 0.5-1.0%, nucleating agent 0.1-0.3%;

[0037] S02: Mix polyphthalamide, graphite, aluminum nitride, flame retardant, heat stabilizer and nucleating agent uniformly to obtain mixed raw materials;

[0038] S03: Put the above-mentioned mixed raw materials in a twin-screw extruder to blend with carbon fibers, melt extrude, and granulate to obtain the high-strength antistatic and heat-conducting PPA material.

[0039] In step S01, all materials are accurately weighed to an accuracy of 0.001 kg, put into corresponding material bags and marked.

[0040] Step S0...

Embodiment 1

[0045] The components and weight percentages of the high-strength antistatic heat-conducting PPA material of the present embodiment are:

[0046] Polyphthalamide 35%;

[0047] Carbon fiber 25%;

[0048] Graphite 9%;

[0049] Aluminum nitride 20%;

[0050] Flame retardant 10%;

[0051] Heat stabilizer 0.8%;

[0052] Nucleating agent 0.2%.

[0053]Wherein, the polyphthalamide resin is produced by Solvay Company, the semi-crystalline resin of trade name A-1000; the carbon fiber is produced by Japan Toray Company, and the trade name is T300-T6 chopped length Chopped fibers at 5 to 8mm; the colloidal graphite produced by Qingdao Baichuan Co., Ltd. with a brand name of TF-1; type aluminum nitride; the flame retardant is a hypophosphite halogen-free flame retardant with a brand name of OP1230 produced by Clariant; The synergistic mixture of phenolic antioxidant and phosphate; Described nucleating agent is the calcium salt of carboxylate based on the long carbon chain compositi...

Embodiment 2

[0056] The components and weight percentages of the high-strength antistatic heat-conducting PPA material of the present embodiment are:

[0057] Polyphthalamide 45%;

[0058] Carbon fiber 20%;

[0059] graphite 7%;

[0060] Aluminum nitride 15%;

[0061] Flame retardant 12%;

[0062] Heat stabilizer 0.8%;

[0063] Nucleating agent 0.2%.

[0064] Wherein, the polyphthalamide resin is produced by Solvay Company, the semi-crystalline resin of trade name A-1000; the carbon fiber is produced by Japan Toray Company, and the trade name is T300-T6 chopped length Chopped fibers at 5 to 8mm; the colloidal graphite produced by Qingdao Baichuan Co., Ltd. with a brand name of TF-1; type aluminum nitride; the flame retardant is a hypophosphite halogen-free flame retardant with a brand name of OP1230 produced by Clariant; The synergistic mixture of phenolic antioxidant and phosphate; Described nucleating agent is the calcium salt of carboxylate based on the long carbon chain composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com