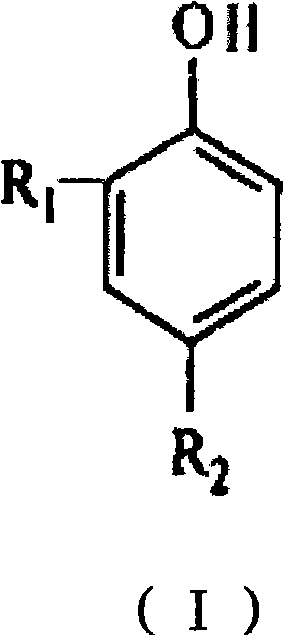

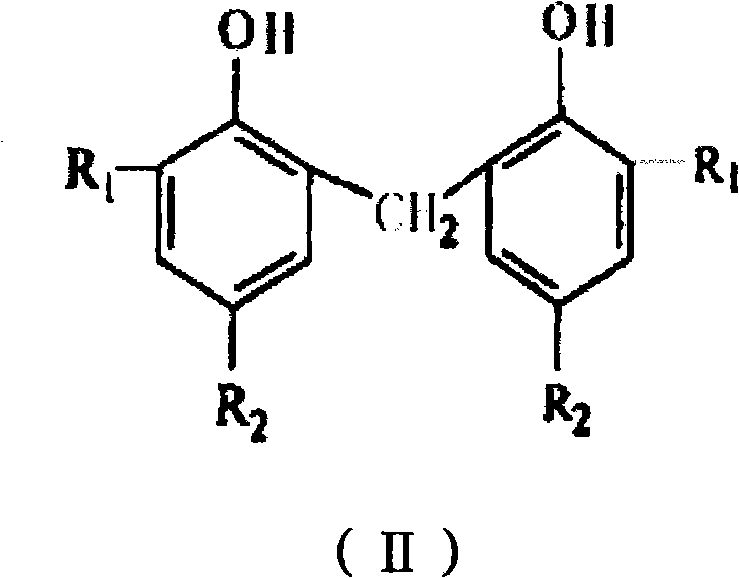

Preparation method of organic phosphate polypropylene nucleating agent

A polypropylene nucleating agent and organophosphate technology, applied in the petrochemical field, can solve problems such as unfavorable environmental protection, large exhaust gas smell, complicated operation, etc., and achieve the effects of easy operation, environmental protection, and overcoming many equipments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Add 250ml of water, 41.27g of 2,4-di-tert-butylphenol and 20ml of 37% formaldehyde into the reaction kettle, stir until the solid is fully dissolved, add 0.5g of sodium dodecylsulfonate at room temperature, and slowly add 98 % sulfuric acid 5ml, react at room temperature for 2 hours after the dropwise addition; then stir for 1.5 hours, then insert a suction filter tube with a mesh of 80 μm filter into the reactor to depressurize and extract water out of the reactor, and drain it. Then inject water into the reaction kettle, stir and wash, then insert the suction filter tube equipped with a filter into the reaction kettle to depressurize and extract the filtrate water out of the reaction kettle. Repeat several times until the pH is neutral. Stir and heat up to 80 degrees to dry.

[0068] After drying, add 160ml of toluene and 60ml of triethylamine into the original reaction kettle, stir until the solid is fully dissolved, slowly add 20ml of phosphorus oxychloride at room...

Embodiment 2

[0071] Add 250ml of water, 41.27 grams of 4-methyl-6-tert-butylphenol and 20ml of 37% formaldehyde in the reaction kettle, stir until the solid is fully dissolved, add 0.5 grams of sodium dodecylsulfonate at room temperature, slowly Add 5ml of 98% sulfuric acid, and react at room temperature for 2 hours after the dropwise addition; then stir for 1.5 hours, then insert a suction filter tube with a mesh of 80 μm filter screen into the reactor to depressurize and extract the filtrate out of the reactor. Dry. Then inject water into the reaction kettle, stir, and then use a suction filter tube equipped with a filter screen to insert into the reaction kettle to depressurize and extract the filtrate water out of the reaction kettle. Repeat several times until the pH is neutral. Stir and heat up to 80 degrees to dry.

[0072] After drying, add 160ml of toluene and 60ml of triethylamine into the original reaction kettle, stir until the solid is fully dissolved, slowly add 20ml of pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com