Separation and purification process for L-tryptophane

A technology for separation and purification of tryptophan, applied in the field of separation and purification of L-tryptophan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

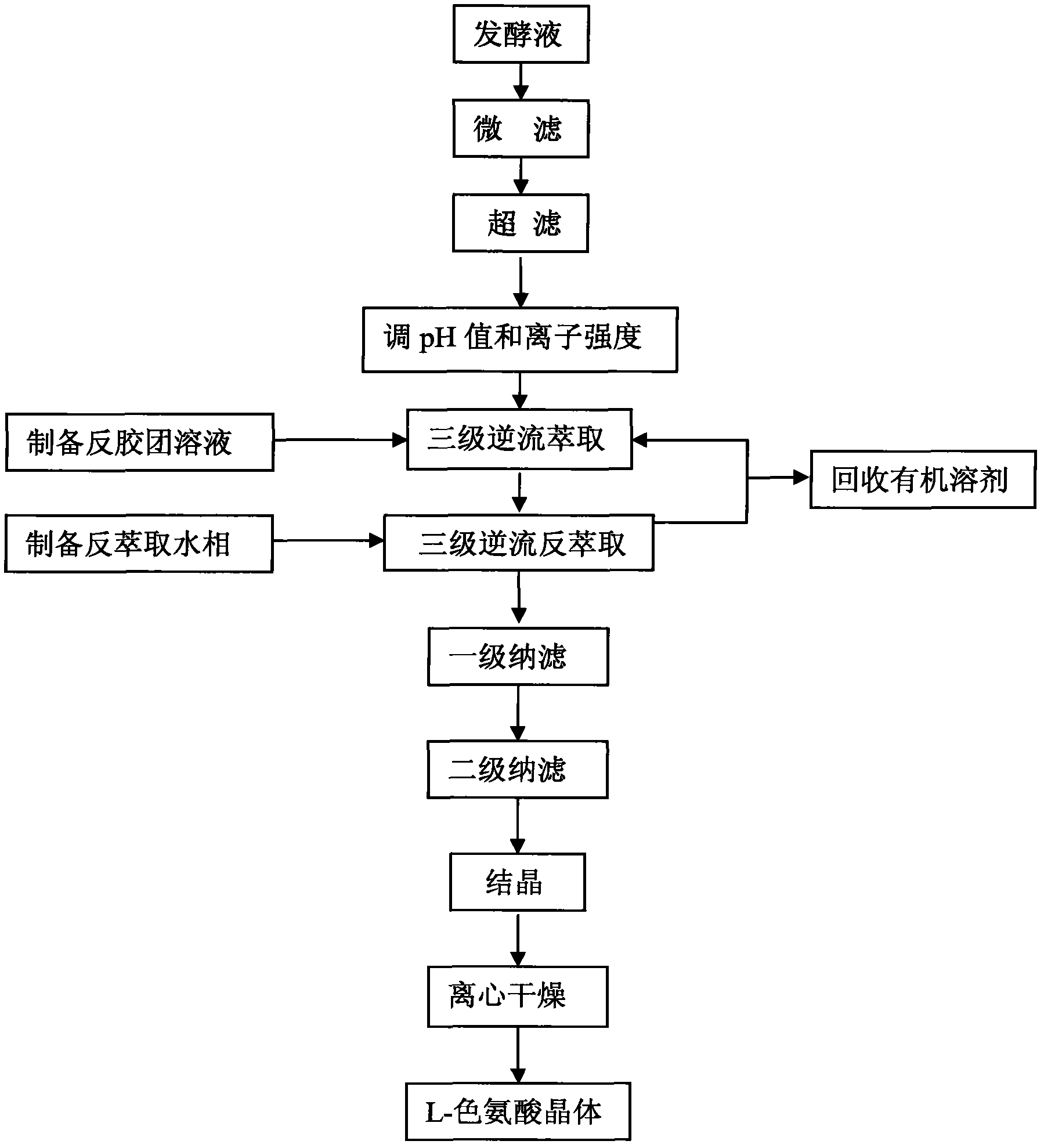

Image

Examples

Embodiment 1

[0024] After diluting 5 L of L-tryptophan fermentation liquid with a concentration of 28.4 g / L by 1 time, use a 0.2 μm microfiltration membrane to filter and sterilize at 60° C. to obtain 9.5 L of sterilized liquid.

[0025] The sterilizing solution is ultrafiltered through a membrane with a molecular weight cut-off of 1000. The ultrafiltration temperature is 60°C to remove protein, macromolecular impurities and pigments. The pH of the permeate is adjusted to 2.5 with hydrochloric acid, and the ionic strength is adjusted to 0.15M by adding KCl to obtain 9.3 L of extracted aqueous phase, ready for reverse micelles extraction.

[0026] Adopt centrifugal extractor to carry out three-stage counter-current extraction to the filtrate that adjusts ion concentration and pH value, extraction condition is: organic phase: water phase=1: 2, organic phase is AOT / isooctane (AOT concentration is 60mmol / L) , three-stage countercurrent extraction was carried out at a temperature of 20° C. and ...

Embodiment 2

[0030] After diluting 4 L of L-tryptophan fermentation broth with a concentration of 32.5 g / L by 1 time, use a 0.15 μm microfiltration membrane to filter and sterilize at 80° C. to obtain 7.8 L of sterilized solution.

[0031] The sterilizing solution is ultrafiltered through a membrane with a molecular weight cut-off of 1000. The ultrafiltration temperature is 60°C to remove protein, macromolecular impurities and pigments. The pH of the permeate is adjusted to 2.5 with hydrochloric acid, and the ionic strength is adjusted to 0.15M by adding KCl to obtain 7.5 L of the extracted aqueous phase, ready for reverse micelles extraction.

[0032] Adopt centrifugal extractor to carry out three-stage countercurrent extraction to the filtrate that has adjusted ion concentration and pH value, and extraction condition is: organic phase: aqueous phase=1: 5, and organic phase is AOT / isooctane (AOT concentration is 80mmol / L) , the organic phase and the aqueous phase were mixed for three-sta...

Embodiment 3

[0036] After diluting 2L of L-tryptophan fermentation broth with a concentration of 26g / L by 1 time, use a 0.05μm microfiltration membrane to filter and sterilize at 40°C to obtain 3.8L of filtrate.

[0037] The filtrate was ultrafiltered through a membrane with a molecular weight cut-off of 1000. The ultrafiltration temperature was 40°C to remove protein, macromolecular impurities and pigments. The pH of the permeate was adjusted to 2.0 with hydrochloric acid, and the ionic strength was adjusted to 0.10M by adding KCl to obtain 3.5L The extracted aqueous phase is ready for reverse micellar extraction.

[0038] Adopt centrifugal extractor to carry out three-stage countercurrent extraction to the filtrate that adjusts pH value and ion concentration, extraction condition is: organic phase: water phase=1: 1, organic phase is AOT / isooctane (AOT concentration is 40mmol / L) , the organic phase and water were subjected to three-stage countercurrent extraction at an equal volume ratio,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com