Sand feeding method in manufacturing process of diamond roller

A technology of diamond roller and manufacturing process, which is applied in the direction of manufacturing tools, metal processing equipment, grinding devices, etc. It can solve the problems of low sanding efficiency, difficult processing of diamond rollers, and inability to process large-grained diamonds, and achieve high-efficiency sanding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

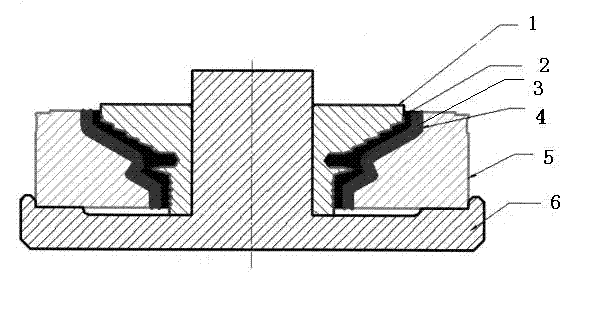

[0018] figure 1 It is a schematic diagram of the casting of the diamond roller manufacturing process, 1 is the mandrel, 2 is the low melting point alloy, 3 is the coating, 4 is the diamond layer, 5 is the female mold, and 6 is the casting fixture; figure 2 It is a hierarchical structure diagram of a diamond roller, including a mandrel 1, a low melting point alloy 2, a coating 3, and a diamond layer 4.

[0019] Such as figure 1 As shown, the manufacturing process of the diamond roller is divided into: the first step, use the forming tool to turn the curved surface required by the part on the female mold, such as image 3 Shown, flat type female mold 51, right-angle type female mold 52, curve type female mold 53 etc.; The second step is the sanding process of covering one deck diamond on the curved surface; First, make a V-shaped pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com