Battery possessing phase change material

A phase-change material and phase-change technology, applied in the fields of batteries, secondary batteries, secondary battery manufacturing, etc., can solve problems such as lack of rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

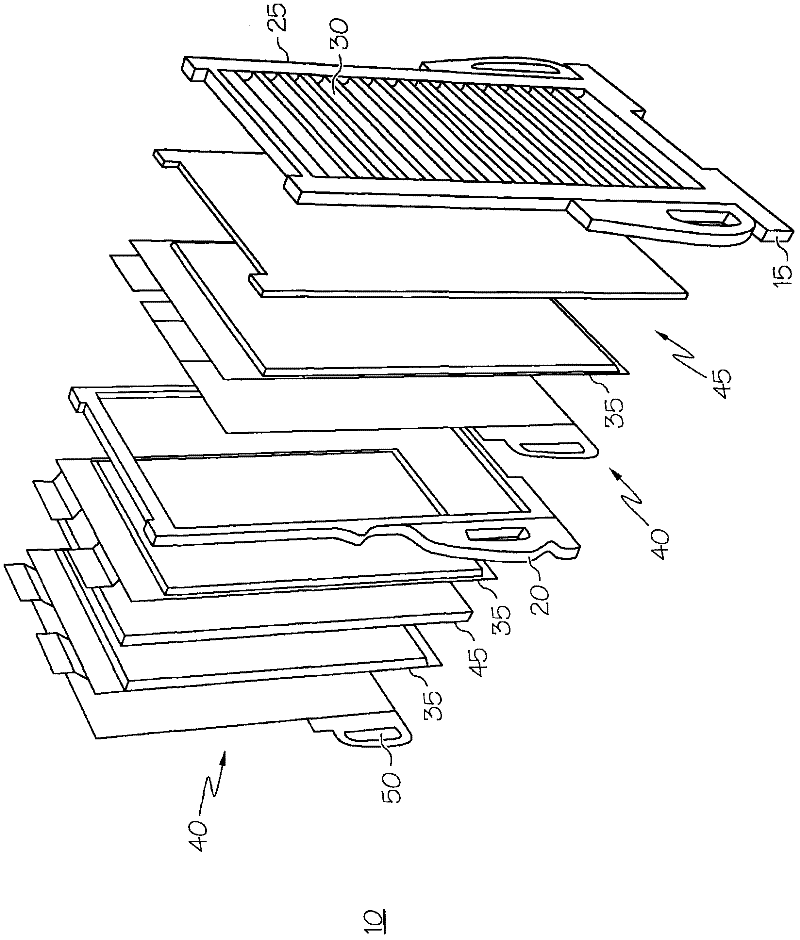

[0037] Batteries with phase change materials (PCM), such as lithium-ion batteries, can improve heating and cooling capabilities under different vehicle operating conditions. PCM can help minimize unwanted operating temperature variations, increase heating and cooling uniformity, and reduce heating and cooling requirements.

[0038] Batteries utilizing PCM are able to control temperature excursions and maintain temperature uniformity with little or no active cooling components such as fans, blowers or pumps present in air / liquid cooling systems. Thus, a compact, light-weight, energy-efficient system can be obtained with energy usage of battery life and performance over the full operating range of hybrid electric vehicles (HEV) / plug-in electric vehicles (PEV) is optimized.

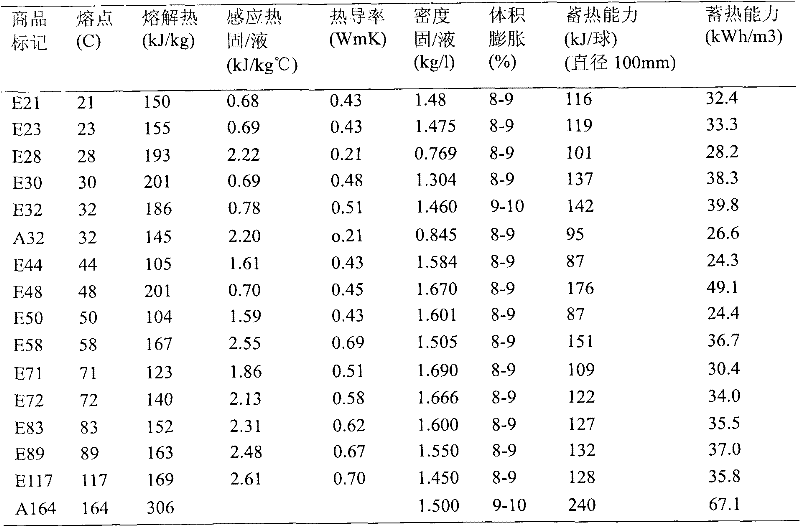

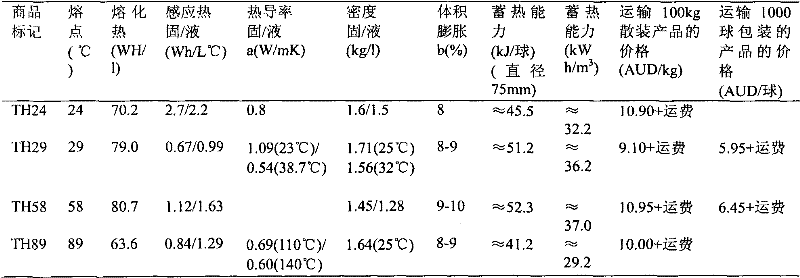

[0039] The thermal performance and heat transfer enhancement methods of various PCMs are described in Kenisarin and Mahkamov, "Solar energy storage using phase change materials", Renewable and Sustainable E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com