A multi-barrel molecular sieve runner intermittent circulation dehumidification dryer

A molecular sieve and circulation technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of energy consumption, excessive cooling water, waste of residual heat, etc., and achieve the reduction of dew point fluctuations and coordination Low equipment requirements and reduced installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

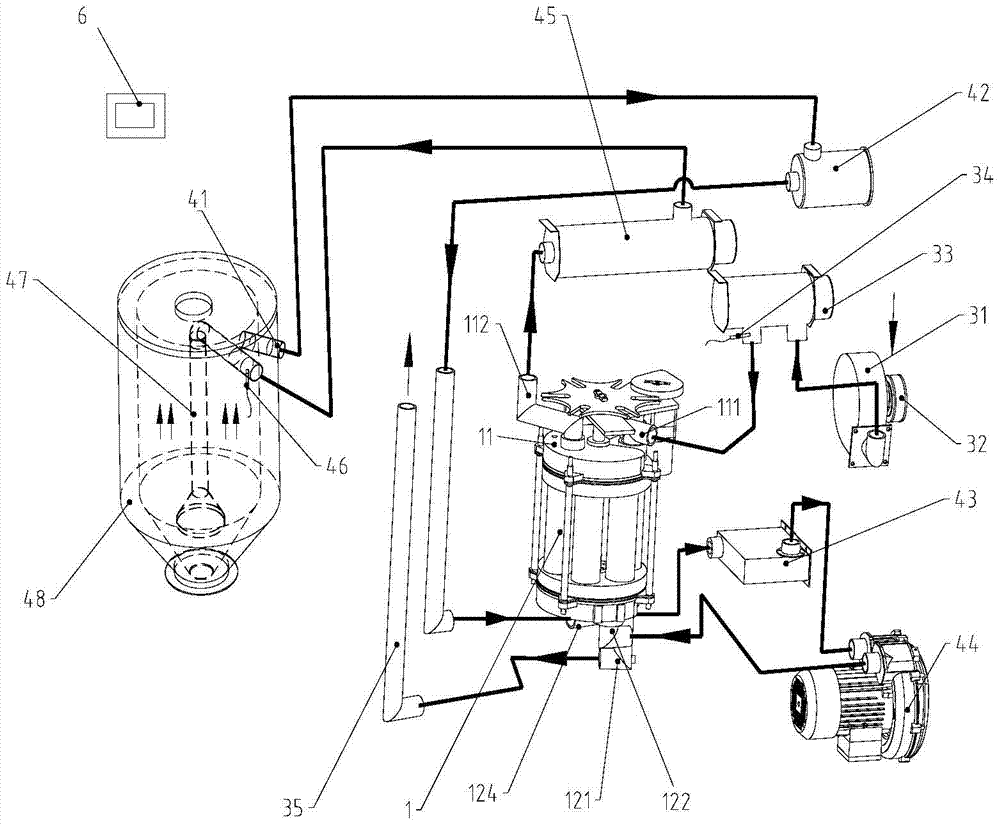

[0069] Such as figure 1 As shown, a multi-barrel molecular sieve runner intermittent circulation dehumidification dryer is used for drying and dehumidifying plastic particles in the drying hopper 48, which includes a multi-barrel molecular sieve runner 1, an intermittent drive mechanism 2, a fan 31, and a first filter 32. The first heater 33, the processing blower 44, the second filter 42, the cooler 43 and the system controller 6.

[0070] Such as image 3 As shown, the multi-barrel molecular sieve runner 1 includes a top cover 11, a bottom cover 12, at least three dehumidification barrels 14 between the top cover 11 and the bottom cover 12, a positioning guide post 13, a porous plate 15, a rotating base 16, Gasket 17 and bearing 18.

[0071] Such as Figure 5 As shown, the bottom cover 12 has an internal passage and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com