Multi-group multi-barrel molecular sieve runner alternate intermittent cycle dehumidification dryer

A molecular sieve, circulating technology, used in non-progressive dryers, dryers, drying and other directions, can solve problems such as energy consumption, excessive cooling water, waste of residual heat, etc. Low requirements and the effect of reducing installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

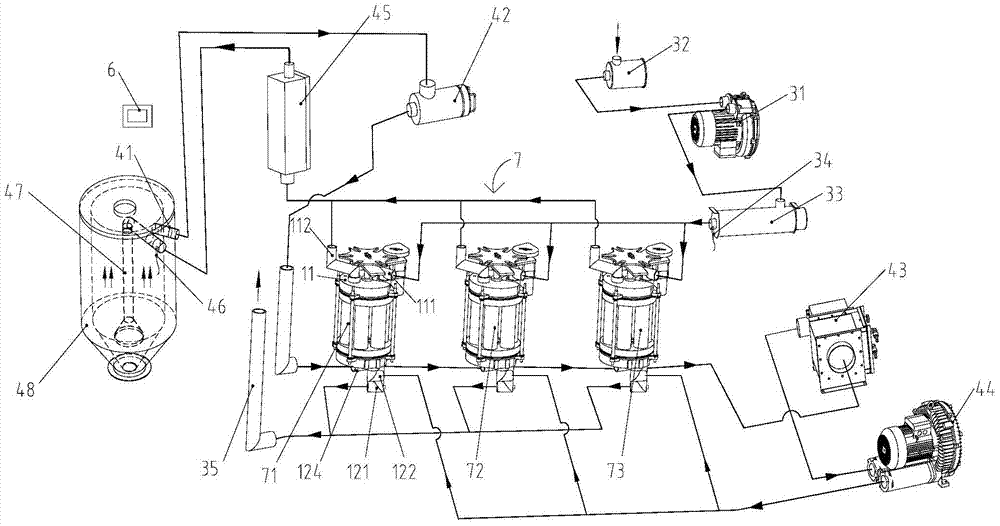

[0072] Such as figure 1 As shown, a multi-group multi-barrel molecular sieve runner alternate intermittent cycle dehumidification dryer is used for drying and dehumidification of plastic particles in the drying hopper 48, which includes at least two multi-barrel dehumidification runner groups 7 connected in parallel, preferably for example for 3 pcs.

[0073] The three multi-barrel dehumidification runners 7 are respectively the first multi-barrel dehumidification runner 71, the second multi-barrel dehumidification runner 72 and the third multi-barrel dehumidification runner 73. The three multi-barrel dehumidification runners 7 Alternate interval cycles.

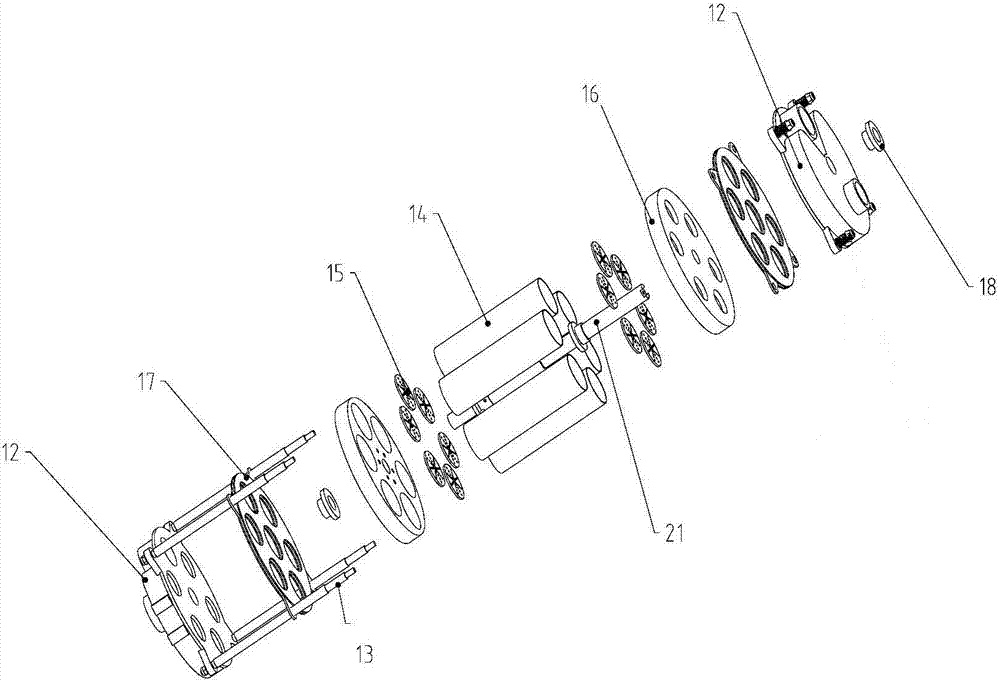

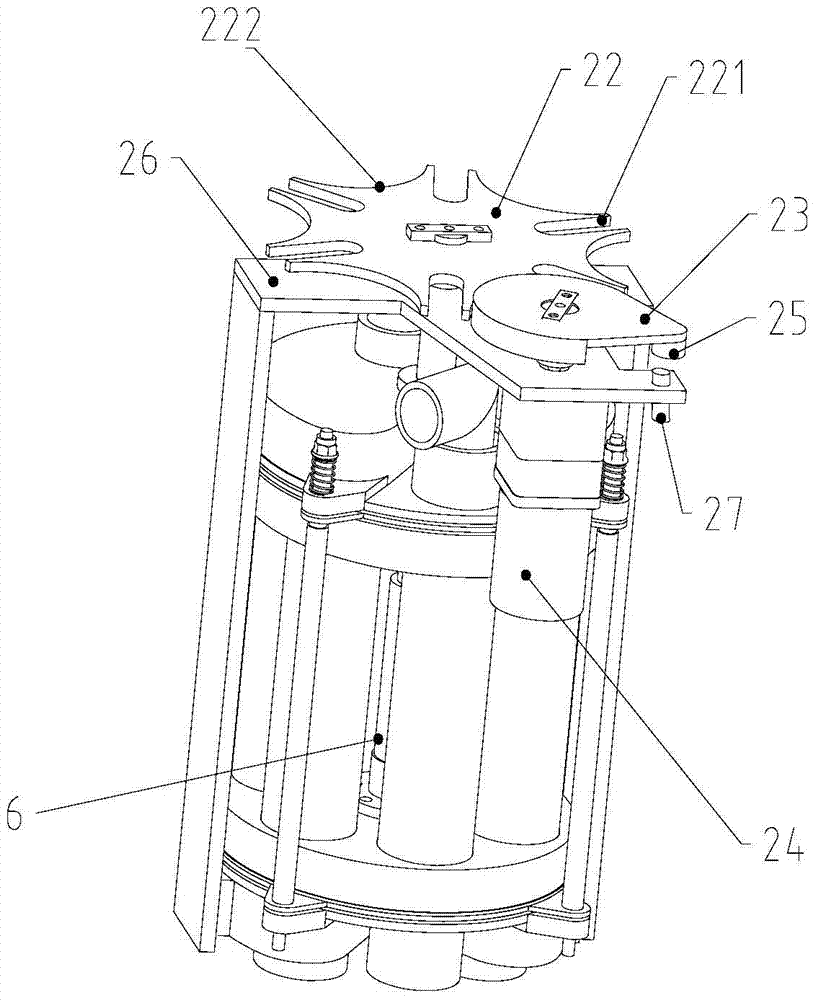

[0074] Each multi-barrel dehumidification runner group 7 includes a multi-barrel molecular sieve runner 1, an intermittent drive mechanism 2, a fan 31, a first filter 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com