Radioactive Ray Sensitive Resin Composite, Solidification Film, Preparing Method Of Solidification Film, Color Filter And Preparing Method Of Color Filter

A technology of resin composition and radiation, which is applied in the direction of equipment, optical filter, photoplate making process of pattern surface, etc., can solve the problems of lower storage stability, compression characteristics of cured film, heat resistance, relative dielectric constant and solvent resistance In order to avoid problems such as unsatisfactory resistance, hardness, and voltage retention rate, and no pattern, etc., it achieves the effect of excellent voltage retention rate, storage stability, hardness, and voltage retention rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0189]

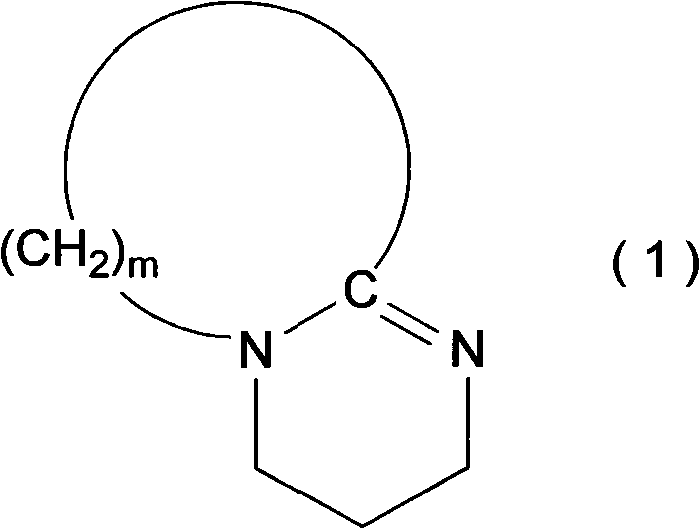

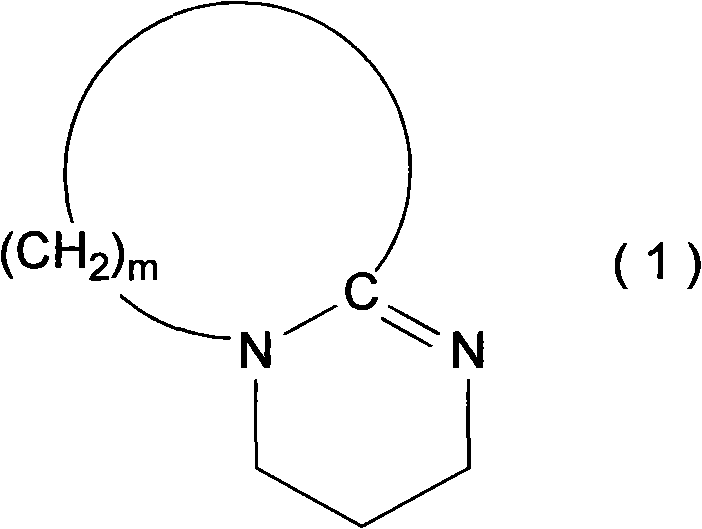

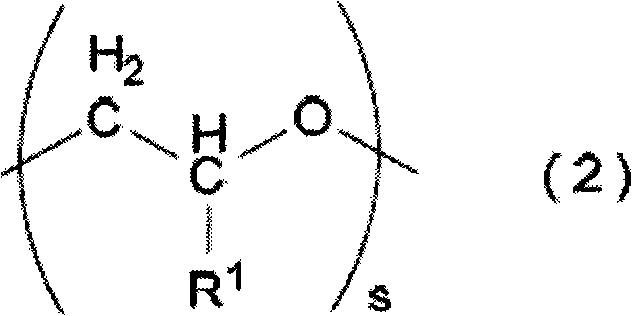

[0190] In addition to mixing [A] alkali-soluble resin, [B] polymerizable compound, [C] radiation-sensitive polymerization initiator, [D] compound, and [E] compound, the radiation-sensitive resin composition of the present invention may optionally , to prepare by mixing optional ingredients in a prescribed ratio. This radiation-sensitive resin composition can be prepared by mixing an amidine salt formed of [D] compound and [E] compound with [A] alkali-soluble resin, [B] polymerizable compound, and [C] radiation-sensitive polymerization initiator . Through the above steps, the radiation-sensitive resin composition containing the amidine salt can be efficiently produced.

[0191] As the solvent used in the preparation of the radiation-sensitive resin composition, one that can uniformly dissolve or disperse the components but does not react with the components can be used. Examples of the solvent include the same ones as those exemplified as solvents that can be used ...

Embodiment

[0238] Hereinafter, the present invention will be described in detail based on examples, but the present invention is not limitedly interpreted in these examples.

[0239]

Synthetic example 1

[0241] In a flask with a condenser and a stirrer, 7 parts by mass of 2,2'-azobis(2,4-dimethylvaleronitrile) and 200 parts by mass of diethylene glycol ethyl methyl ether were added. Then add 16 parts by mass of methacrylic acid as (A1) compound, 20 parts by mass of glycidyl methacrylate as (A2) compound and 16 parts by mass of tricyclic [5.2.1.0 as (A3) compound 2.6 ] Dec-8-yl methacrylate, 38 parts by mass of methyl methacrylate and 10 parts by mass of styrene, after replacing with nitrogen, slowly stirred, and the solution was heated to 70 ° C, and kept at this temperature for 4 hours to carry out polymerization, Thus, a solution (solid content concentration=34.4% by mass, Mw=8000, Mw / Mn=2.3) containing the copolymer (A-1) was obtained. In addition, the solid content concentration refers to the ratio of the copolymer mass to the total mass of the copolymer solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com