Color composition for pixel-forming ink, pigment dispersion liquid, pixel-forming ink, color filter, and production methods thereof

A technology for coloring composition and manufacturing method, which is applied in the direction of ink, pigment paste, photoplate making process of patterned surface, etc., can solve the problems of reduced physical properties of dispersed pigments, color tone changes, etc., and achieve high color concentration and high fineness , high transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Example 1 (Preparation of Cyan Pigment Dispersion Used in CF Applications)

[0102] (a) Micronization of cyan pigments used in CF applications

[0103] PB15:6 (ε-type copper phthalocyanine blue pigment, called "cyan pigment-1") is subjected to micronization treatment for use as a cyan pigment in CF applications. Mix 90 parts of PB15:6, 5 parts of copper phthalocyanine monosulfonated derivatives, and 5 parts of copper phthalocyanine phthalimide methyl derivatives, and add them together with 400 parts of sodium chloride and 130 parts of diethylene glycol In a kneader fitted with a pressurized lid. Pre-mix in the kneader until a uniform wet mass is formed, then close the pressurized lid at 6kg / cm 2 Kneading and grinding were performed for 7 hours while squeezing the contents under high pressure. Put the obtained ground material into 3000 parts of 2% sulfuric acid aqueous solution and stir it for 1 hour, then filter it with a filter press to remove sodium chloride and di...

Embodiment 2

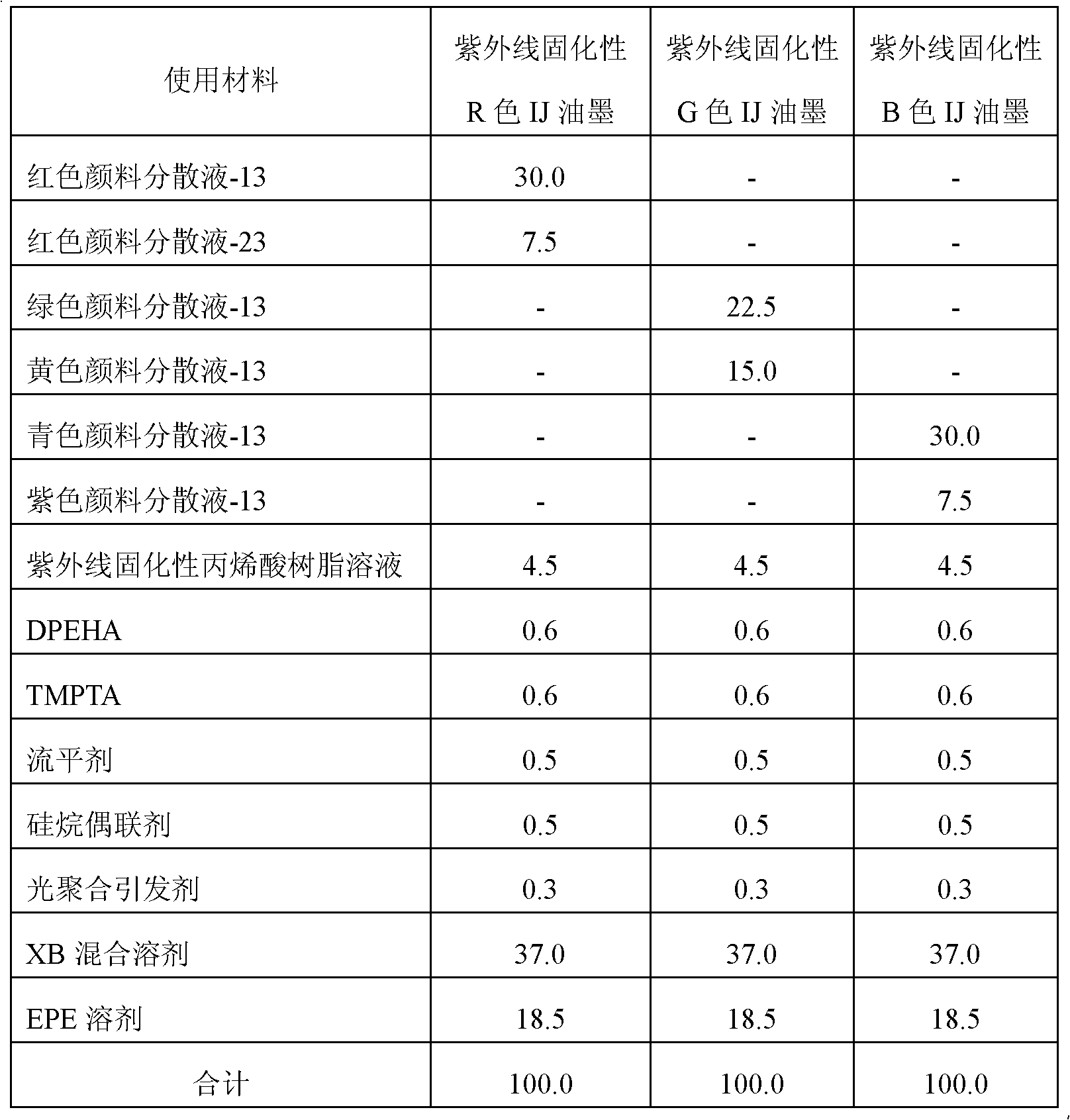

[0111] Embodiment 2 (preparation of various colored pigment dispersions)

[0112] (a) Micronization of various pigments used in CF applications

[0113] Other pigments used for CF were ground in the same manner as in Example 1(a). Instead of PB15:6 used in Example 1(a), PR177 (anthraquinone-based red pigment, referred to as "Red Pigment-1"; hereinafter the same), PR254 (diketopyrrolopyrrole-based red pigment, "red pigment -2"), PR242 (high molecular weight disazo red pigment, "red pigment-3"), PG36 (bromo-chlorinated copper phthalocyanine green pigment, "green pigment-1"), PG58 (bromo-chlorinated Zinc phthalocyanine green pigment, "green pigment-2"), poly(13~16) brominated copper phthalocyanine green pigment, "green pigment-3"), PG7 (copper chloride phthalocyanine green pigment, "green pigment- 4"), PY150 (nickel complex azo-based yellow pigment, "Yellow Pigment-1"), PY138 (quinophthalone-based yellow pigment, "Yellow Pigment-2") and PV23 (dioxazine purple pigment, "Yellow P...

Embodiment 3

[0125] Preparation of "Pigment Dispersion Liquid (2)" of various colors used in the application of Example 3CF

[0126] (a) Preparation of "Pigment Color Paste (2)"

[0127] In the same manner as in Example 1(b), 10 parts of XB solvent and 50 parts of 40% XB solution of polymer dispersant-1 were added to a water squeezer equipped with a heating device and a vacuum distillation device, and they were uniformly mixed. 40 parts of the filter paste of the micronized cyan pigment obtained in Example 1 (a) and the red pigment, green pigment, yellow pigment, and purple pigment obtained in Example 2 (a) were added thereto in terms of solid content. The filter paste of each micronized pigment is squeezed after kneading. The separated water was discharged to the outside of the system, and the residual water was distilled off by operating the vacuum distillation apparatus while kneading. Next, the obtained squeeze color pastes of pigments of various colors were kneaded using a twin-roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com