Mn-Fe composite pellet and preparation method thereof

A technology of composite pellets and ferromanganese, which is applied in the production of manganese-based alloy raw materials, can solve the problems of lower furnace grade, high ferromanganese ratio, power consumption, and unsatisfactory economic and technical indicators of recovery rate, etc., so as to improve the furnace grade , Reduce the weight ratio of ferromanganese and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

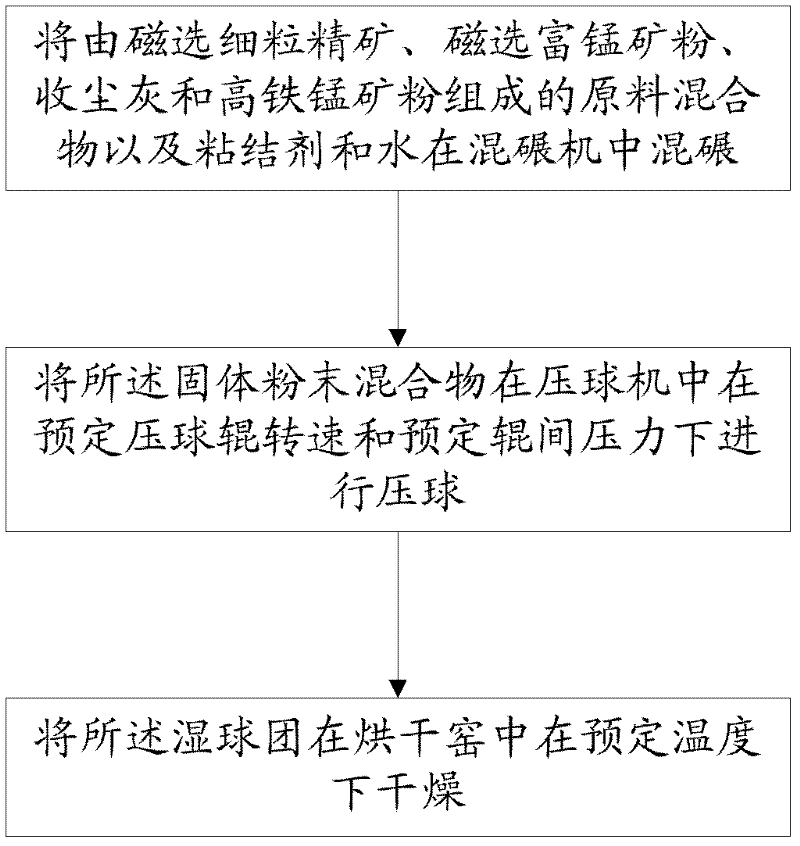

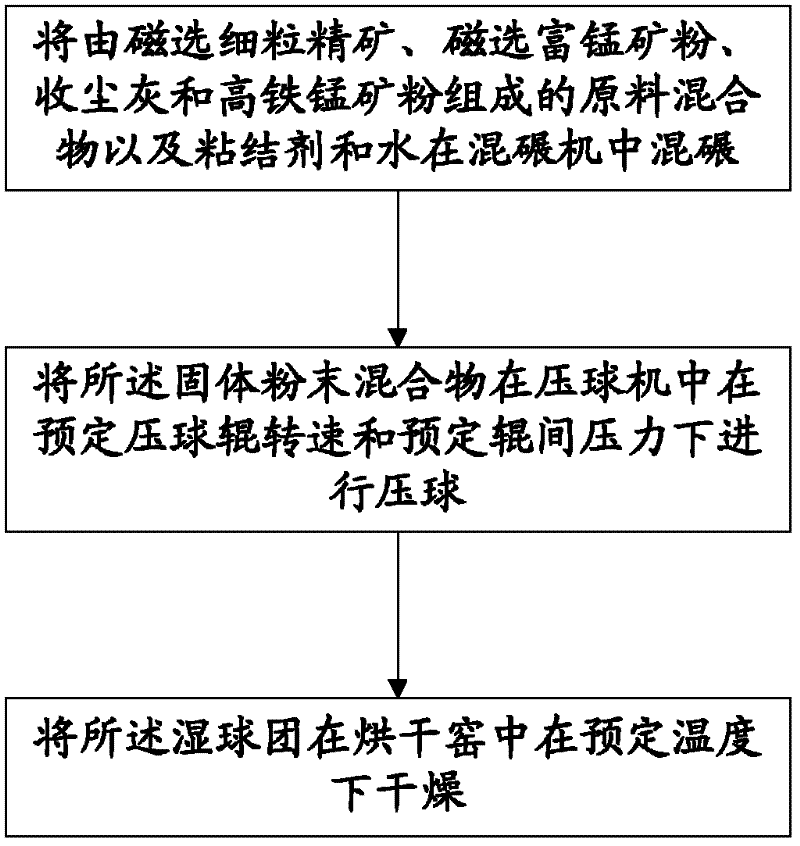

[0047] In the mixing mill, 40 parts by weight of magnetically separated fine ore concentrate, 20 parts by weight of magnetically separated manganese-rich ore powder, 30 parts by weight of dust collection ash, 10 parts by weight of ferromanganese ore powder, and 1.5 parts by weight of bonding The powder and appropriate amount of water were mixed and milled for 6 minutes to obtain a solid powder mixture. Then, in the briquetting machine, the solid powder mixture was briquetted at a briquetting roller speed of 6 rpm and an inter-roll pressure of 5 MPa to obtain wet pellets. Finally, in a drying kiln, the wet pellets were dried at 200 degrees Celsius for 3 hours to obtain ferromanganese composite pellets. Tested by a dynamometer, the compressive strength of the composite pellets was 36MPa, indicating that the quality of the pellets was qualified.

Embodiment 2

[0049] In the mixing mill, 40 parts by weight of magnetically separated fine ore concentrate, 20 parts by weight of magnetically separated manganese-rich ore powder, 30 parts by weight of dust collection ash, 10 parts by weight of ferromanganese ore powder, and 2 parts by weight of sticky The binder and an appropriate amount of water were mixed and milled for 7 minutes to obtain a solid powder mixture. Then, in the briquetting machine, the solid powder mixture was briquetted at a briquetting roller speed of 8 rpm and an inter-roll pressure of 4 MPa to obtain wet pellets. Finally, in a drying kiln, the wet pellets were dried at 180 degrees Celsius for 2.5 hours to obtain ferromanganese composite pellets. Tested by a dynamometer, the compressive strength of the composite pellets was 38MPa, indicating that the quality of the pellets was qualified.

Embodiment 3

[0051] In the mixing mill, 40 parts by weight of magnetically separated fine ore concentrate, 20 parts by weight of magnetically separated manganese-rich ore powder, 30 parts by weight of dust collection ash, 10 parts by weight of ferromanganese ore powder, and 2.5 parts by weight of sticky The binder and an appropriate amount of water were mixed and milled for 8 minutes to obtain a solid powder mixture. Then, in the briquetting machine, the solid powder mixture was briquetted at a briquetting roller speed of 9 rpm and an inter-roll pressure of 7 MPa to obtain wet pellets. Finally, in a drying kiln, the wet pellets were dried at 210 degrees Celsius for 5 hours to obtain ferromanganese composite pellets. The compressive strength of the composite pellets was 40MPa after testing by a dynamometer, indicating that the quality of the pellets was qualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com